Leave Your Message

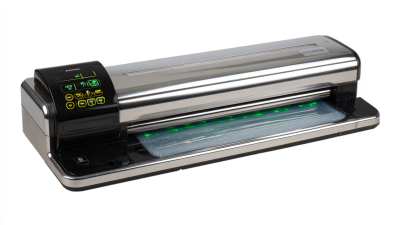

In today’s fast-paced business environment, efficiency and protection of products during transportation and storage are paramount. One innovative solution that has gained popularity across various industries is the Shrink Packing Machine. This cutting-edge technology not only enhances the presentation of goods but also provides a robust layer of protection against external factors such as dust, moisture, and tampering. Businesses that adopt shrink packing machines can significantly reduce the risk of product damage, ensuring that their products reach customers in pristine condition.

Moreover, the use of a shrink packing machine can streamline the packaging process and improve operational efficiency. By automating the packaging tasks, businesses can save time and labor costs, allowing employees to focus on more critical functions that drive growth. As companies continue to seek competitive advantages, the strategic implementation of shrink packing technology can serve as a game changer, providing both quality and cost-effectiveness in product presentation.

In summary, the Shrink Packing Machine offers a multitude of benefits that cater to the diverse needs of businesses looking to enhance their packaging solutions. From improving product protection and aesthetic appeal to increasing operational efficiency, this technology stands out as an essential tool for modern enterprises aiming for success in their respective markets.

Shrink packing machines have become indispensable in various industries, particularly due to their ability to enhance product protection. These machines utilize heat to shrink plastic films tightly around products, providing a robust barrier against environmental factors such as moisture, dust, and physical damage. According to a report by the Freedonia Group, the demand for shrink packaging in the U.S. alone is expected to reach $2.7 billion by 2024, highlighting the growing recognition of its benefits among businesses.

One of the key advantages of using shrink packing machines is their contribution to extending shelf life. Products that are well-sealed in shrink films are less susceptible to contamination, leading to reduced spoilage rates. A study published in "Packaging Technology and Science" noted that products stored in shrink-wrapped packaging showed a 15-20% longer shelf life compared to those in traditional packaging. This is particularly advantageous for perishable goods and can result in significant cost savings for businesses by minimizing losses due to damaged or expired items.

Moreover, shrink packaging enhances product visibility and branding while maintaining protection. High-quality shrink films can be printed with vibrant graphics, drawing consumer attention while simultaneously safeguarding the contents. As per a report from MarketsandMarkets, the global shrink packaging market is projected to grow at a compound annual growth rate (CAGR) of 4.9% from 2021 to 2026, indicating a heightened awareness among companies regarding the dual benefits of enhanced protection and marketing potential offered by shrink packing machines.

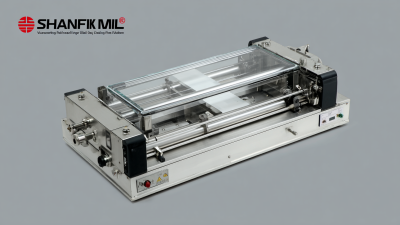

Shrink packing machines have revolutionized packaging processes for businesses, significantly enhancing both efficiency and speed. These machines streamline the workflow by automating tasks that would typically require manual labor. When packaging products, the shrink wrapping method provides a tight, protective seal that not only preserves the quality of the items but also facilitates faster processing times. This automation minimizes human error, ensuring a consistent packaging quality that meets industry standards, which ultimately can lead to reduced labor costs and increased output.

Tips for maximizing the efficiency of shrink packing machines include regular maintenance checks to ensure optimal performance. Keeping the machine well-maintained reduces the chances of breakdowns, which can lead to delays in the packaging process. Additionally, training employees thoroughly on the operation of these machines can result in quicker turnaround times. A well-informed team can easily identify and resolve minor issues without significant downtime.

Another tip is to optimize the layout of the packaging area. Positioning the shrink packing machine near the production line can further reduce handling times, allowing for a smoother transition from production to packaging. By considering these factors, businesses can leverage shrink packing machines to enhance their overall efficiency and speed in packaging processes.

Shrink packing machines offer a variety of advantages that can significantly enhance the efficiency of business operations, especially in terms of cost-effectiveness. One of the primary benefits lies in their ability to reduce material waste. Traditional packing methods often require excessive materials that go beyond the actual needs of the products, leading to inefficiency and added costs. With shrink packing, the film molds tightly around the product, minimizing excess and ensuring that only the necessary amount of material is used. This not only cuts down on packaging expenses but also supports sustainability efforts by producing less waste overall.

In addition to reducing material costs, shrink packing machines can streamline labor efforts. Automation in packaging processes typically means that fewer workers are required for the same amount of packing work, translating to lower labor costs. Employees can be reassigned to other critical tasks, enhancing overall productivity within the organization. Furthermore, the speed and consistency of shrink packing machines lead to quicker turnaround times, which can positively impact order fulfillment and customer satisfaction. Overall, the integration of shrink packing into business operations provides a dual advantage of cutting costs while boosting efficiency.

Shrink packing machines offer exceptional versatility that makes them an ideal solution for businesses dealing with a wide range of products. These machines can accommodate various product types, from irregularly shaped items to standard packages, ensuring a snug and secure fit. Whether packaging food items, electronics, cosmetics, or other consumer goods, shrink wrapping provides reliable protection while enhancing the presentation of the products.

Moreover, the ability to handle different sizes and configurations adds to the appeal of shrink packing machines. Businesses can easily adjust the machine settings to cater to small individual items or larger bulk packages without compromising quality or efficiency. This adaptability not only streamlines the packaging process but also minimizes downtime, allowing companies to meet diverse customer demands swiftly. By investing in shrink packing technology, organizations can effectively enhance their packaging capabilities, meeting the specific needs of an ever-evolving market.

Shrink wrapping is not just a method of packaging; it’s an effective way to enhance your brand’s presentation and aesthetic appeal. Utilizing shrink packing machines allows businesses to create a polished and professional appearance for their products. The tight, transparent film hugs the contours of the item, highlighting its design while offering a sleek look that can attract potential customers. This clean presentation is essential in a marketplace saturated with options, as it helps products stand out on shelves and online platforms.

Moreover, the aesthetic of shrink wrap can be customized to align with brand identity. Businesses can incorporate printed designs, logos, or promotional messaging directly onto the shrink film, further reinforcing brand recognition. This branding element not only beautifies the product but also communicates to customers that the company cares about quality and detail. By prioritizing aesthetics through shrink packing, companies can effectively influence consumer perceptions, increase perceived value, and ultimately drive sales. In an era where visual appeal is key to attracting customers, investing in shrink packing technology becomes a strategic move for enhancing both product visibility and brand image.

| Benefit | Description | Impact on Business |

|---|---|---|

| Enhanced Aesthetic Appeal | Shrink wrapping provides a sleek and professional look that can attract customers. | Increased customer engagement and purchase likelihood. |

| Product Protection | Protects products from dust, moisture, and damage during handling and transport. | Reduction in product returns and damages. |

| Cost Efficiency | Automating shrink packing can lower labor costs and increase packaging speed. | Improved operational efficiency and lower production costs. |

| Versatility | Suitable for a variety of products and materials, allowing for diverse packaging solutions. | Ability to package multiple products enhances adaptability in the market. |

| Extended Shelf Life | Shrink wrapping can help preserve the freshness and longevity of perishable items. | Increased sales and customer satisfaction due to product quality. |