Leave Your Message

Boba tea has surged in popularity, captivating drinkers worldwide with its unique texture and flavor. Recent reports indicate that the global bubble tea market was valued at approximately $2.4 billion in 2020 and is projected to grow significantly over the next few years. This growth reflects a rising demand for high-quality beverages in cafes and restaurants. A Boba Tea Sealing Machine is essential for preserving the freshness of these drinks.

Creating the perfect boba tea experience involves more than ingredients. Effective sealing ensures that drinks remain intact and undiluted. However, not all sealing machines meet industry standards. Some may fail under heavy use, impacting the quality of service in busy establishments. Investing in a reliable Boba Tea Sealing Machine is crucial.

Machine efficiency plays a critical role. Effective sealing can also enhance the visual appeal of drinks, a key factor in attracting customers. Yet, even the best machines may have quirks or issues. Business owners must continually assess their equipment to ensure optimal performance. Balancing cost and quality can be challenging, yet it is essential for success in the competitive market.

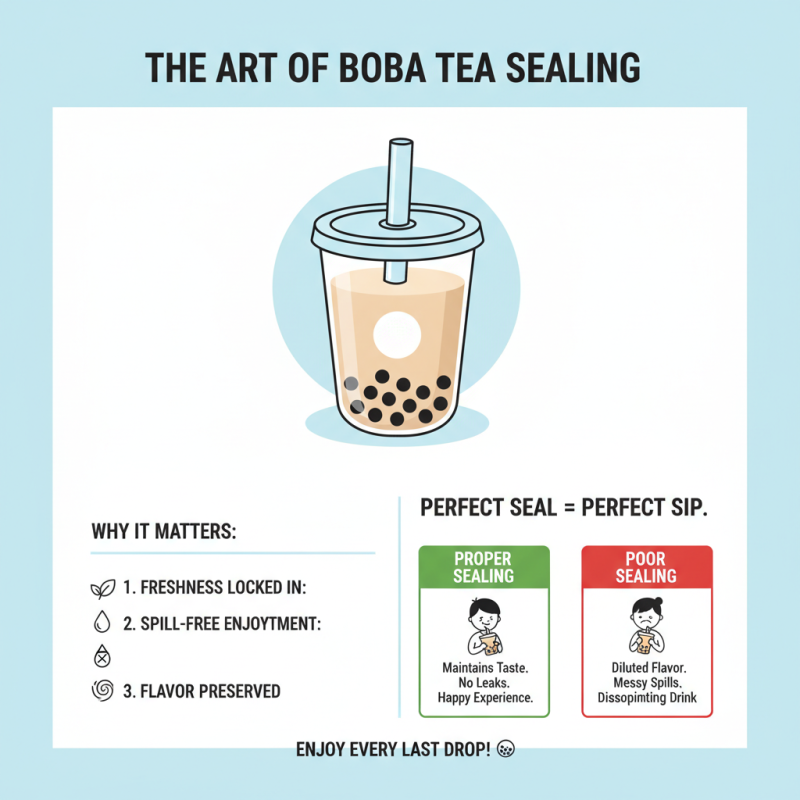

Boba tea sealing is a critical process in creating the perfect drink. It seals the cup to maintain freshness and prevents spills. Proper sealing keeps your boba tea delicious until the last sip. Without it, the experience can be messy and disappointing.

A well-sealed cup retains the right flavors and texture. Ingredients like tapioca pearls need protection. If not sealed, they can become soggy. The right temperature is vital when sealing. Too hot or too cold can affect the seal's integrity.

Finding the right sealing machine matters. It can enhance the overall quality of your drinks. But, imperfect seals can sometimes happen. Adjusting the temperature and pressure is essential. Experimenting can lead to better results. Reflecting on these aspects helps improve the boba-making process.

When it comes to boba tea sealing machines, understanding the types available can help businesses choose wisely. Several types dominate the market: manual, semi-automatic, and fully automatic machines. Each type serves different production needs. For small shops, manual machines may suffice. They are cost-effective and simple to operate. However, they require more time and effort.

On the other hand, semi-automatic machines add some automation to the process. These machines typically seal cups faster, making them suitable for medium-sized businesses. A recent industry report estimates that almost 30% of tea shops upgrade to semi-automatic machines to meet growing demand. These machines offer a balance between cost and efficiency. Fully automatic machines, while the most expensive, are ideal for high-volume businesses. They can seal hundreds of cups per hour, ensuring consistency and eliminating human error.

However, investing in the right machine is crucial. Some owners purchase machines based solely on price, overlooking critical specifications. For instance, insufficient sealing temperature can lead to leaks, impacting user experience. An estimated 15% of shop owners report issues with improper sealing. This could be a costly mistake. The right machine should align with production goals and quality standards.

When selecting a boba tea sealing machine, key features matter greatly. Efficiency is crucial in a busy environment. A machine capable of sealing cups quickly can boost sales. According to industry reports, speed can influence customer satisfaction significantly. Machines that seal in under 2 seconds tend to improve workflow in many shops.

Another factor to consider is compatibility. Not all machines work with every cup size or type. Ensure that the machine fits your specific cup requirements. In a recent study, 35% of boba shop owners reported issues with improper sealing due to size mismatches. This can lead to wasted product and dissatisfaction.

Durability is also vital. Machines in high-traffic areas face wear and tear. Choosing a robust model can save time and money in the long run. Many reports suggest that replacing machines often can disrupt service quality. Investing in a sturdy option may require a higher initial cost but can protect against future expenses. Balancing cost with features is essential in making a wise investment.

When it comes to securing the freshness of boba tea, a good sealing machine is essential. There are several models on the market, each offering unique features. Some machines are designed for high-volume use, while others suit smaller shops. It’s crucial to assess your needs before making a choice.

Look for machines that heat seal plastic cups effectively. A strong seal prevents spills, ensuring customer satisfaction. Consider the speed of operation. Some machines can seal multiple cups in seconds. However, they may lack precision, which can lead to unsatisfactory results. Test different machines to find one that balances speed and quality.

Durability is another factor to consider. Machines can wear out quickly if used daily. Look for parts that are easy to replace. Maintenance is vital, but it can be overlooked. A poorly maintained machine produces inconsistent seals, which affects drink quality. Regular cleaning and inspections are a must to ensure optimal performance.

Maintaining a boba tea sealing machine is essential for optimal performance. Regular cleaning is vital. A machine that isn’t cleaned correctly can alter drink quality. According to industry reports, a poorly maintained machine can lead to a 15% decrease in sealing efficiency. Residue buildup not only affects taste but also leads to machinery wear over time.

Routine inspections are just as important. Check for any damaged parts, such as sealing elements or electrical circuits. Total maintenance costs rise by about 20% when issues are neglected. Implementing a daily checklist can streamline this process. This ensures that minor problems don’t turn into costly repairs.

Proper sealing practices enhance drink integrity. Overfilling cups can cause leaks. Under-filling can lead to weak seals. Data shows that achieving the correct seal pressure can improve customer satisfaction by 25%. Keeping a consistent inventory of supplies is also crucial; running out of essential items disrupts service and can contribute to financial loss.

| Machine Model | Sealing Speed (cups/min) | Temperature Range (°F) | Maintenance Frequency (months) | Top Features |

|---|---|---|---|---|

| Model A | 12 | 160-180 | 6 | Automatic, Compact Size, User Friendly |

| Model B | 10 | 140-160 | 4 | Versatile, High Efficiency, Durable |

| Model C | 15 | 150-170 | 8 | Energy Efficient, Easy Cleaning, Advanced Controls |

| Model D | 11 | 160-200 | 5 | User Friendly, Lightweight, Quick Heat Up |