Leave Your Message

In the rapidly growing bubble tea industry, the efficiency and quality of service can make a significant difference in customer satisfaction and loyalty. One of the essential tools that support this endeavor is the Bubble Tea Sealing Machine. This device not only enhances the presentation of beverages by sealing them securely but also helps maintain the freshness and flavor until the moment they are served. When selecting the right Bubble Tea Sealing Machine for your business needs, it is crucial to consider various factors that align with your operational goals.

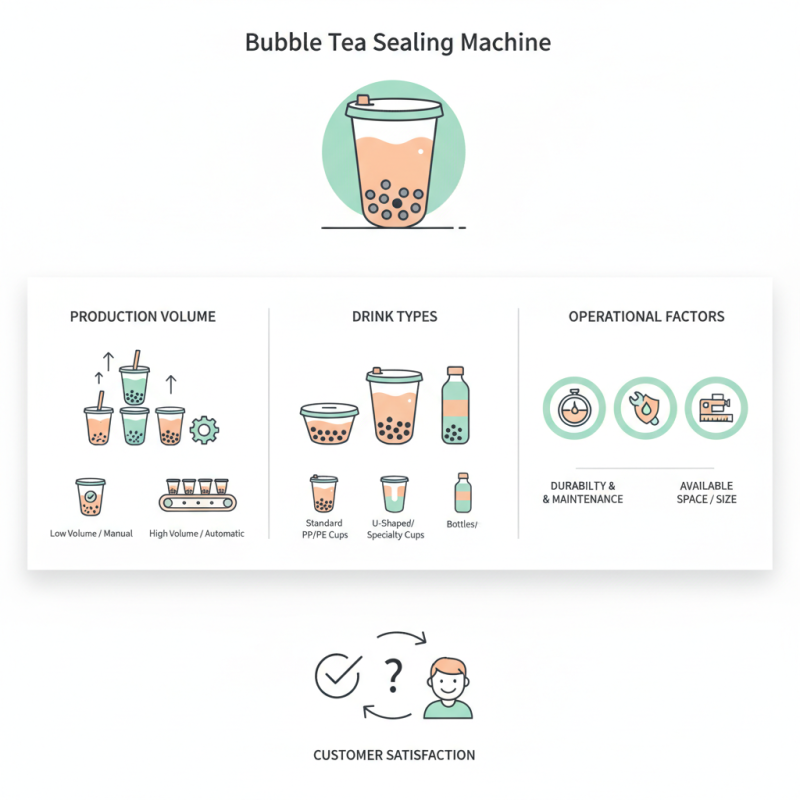

Choosing the best Bubble Tea Sealing Machine involves understanding the specific requirements of your business, such as production volume, type of drinks offered, and available space. Features like sealing speed, durability, and ease of maintenance play vital roles in the decision-making process. This guide will provide insights into the key aspects you need to evaluate to find a Bubble Tea Sealing Machine that perfectly fits your needs, ensuring that you can deliver high-quality beverages that meet customer expectations effectively.

A bubble tea sealing machine plays a vital role in ensuring the quality and freshness of beverages in the bubble tea business. Proper sealing not only enhances the visual appeal of drinks but also preserves their flavors and prevents spills. For businesses, a reliable sealing machine is essential for maintaining customer satisfaction; customers expect their drinks to be perfectly sealed and ready for enjoyment without any mess.

Understanding the importance of a bubble tea sealing machine goes beyond just functionality. A high-quality sealing machine can improve operational efficiency by allowing staff to serve drinks quickly and consistently. Furthermore, it plays a crucial role in food safety by preventing contamination and extending the shelf life of tea, which is particularly important in a fast-paced retail environment. Choosing the right machine means considering factors such as sealing speed, ease of use, and durability to meet the specific demands of your business. As bubble tea continues to grow in popularity, investing in an effective sealing solution can be a key differentiator in a competitive market.

When selecting a bubble tea sealing machine, it's crucial to focus on a few key features that can greatly enhance your business operations. First and foremost, consider the machine's sealing mechanism. There are automatic and semi-automatic options available; automatic machines tend to increase efficiency, whereas semi-automatic machines may offer more control for smaller establishments. Evaluate the sealing technology employed, ensuring it provides consistent seals without compromising the quality of your product. A reliable sealing mechanism prevents leakage and maintains the integrity of your beverages, which is vital for customer satisfaction.

Another important feature to examine is the machine’s compatibility with various cup sizes and materials. Choose a model that can accommodate a range of cup types, from plastic to paper, and adjust to different diameters. This flexibility allows your business to cater to different beverage offerings and seasonal trends, enhancing your capability to adapt to market demands. Additionally, consider the machine's speed and durability. A high-speed machine is essential for busy hours, while robust construction ensures it can withstand the daily rigors of a bustling environment without frequent breakdowns. Prioritizing these features will help you select a sealing machine that meets your operational needs effectively.

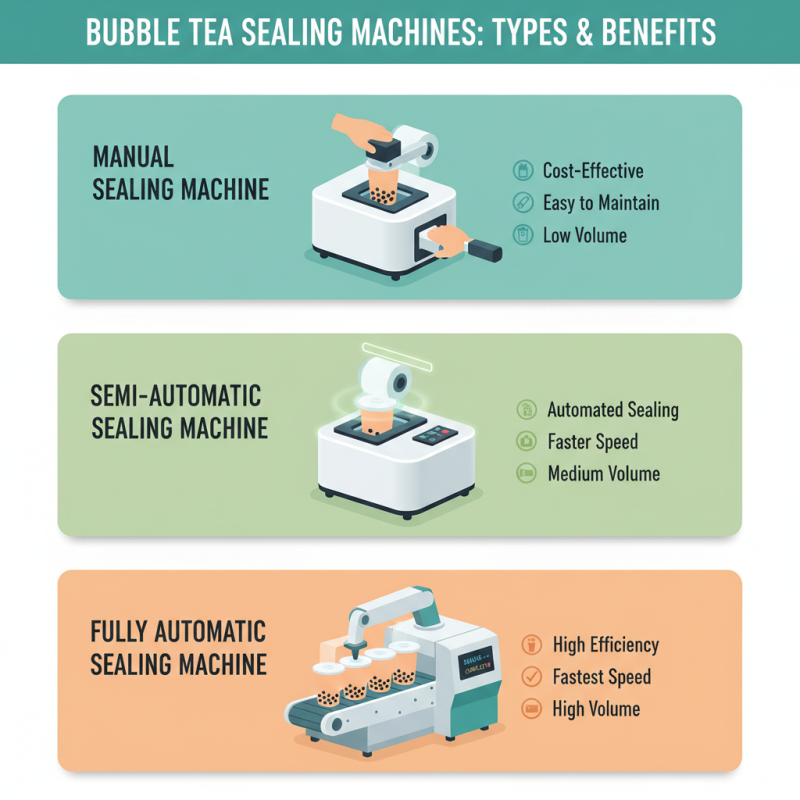

When selecting a bubble tea sealing machine, it's crucial to understand the different types available and how they cater to varying business needs. Generally, bubble tea sealing machines can be classified into manual, semi-automatic, and fully automatic types. Manual machines require the operator to handle most of the process, making them more suited for small businesses or establishments with limited service hours. Despite being labor-intensive, they are cost-effective and easy to maintain.

In contrast, semi-automatic machines streamline some aspects of the sealing process while still requiring human intervention. These machines typically offer adjustable settings for sealing temperatures and times, allowing for better flexibility and consistency. They are ideal for businesses that experience moderate to high customer traffic and are looking to enhance efficiency without committing to a fully automated solution.

Fully automatic bubble tea sealing machines represent the pinnacle of technology, offering the fastest sealing capabilities and the least amount of manual labor. They are equipped with advanced features that ensure high accuracy and repeatability while minimizing the risk of human error. These machines are perfect for high-volume bubble tea shops aiming to maximize production speed and maintain product quality. Assessing the specific demands of your business will help in selecting the right type of sealing machine that optimally balances cost, efficiency, and output.

When choosing a bubble tea sealing machine, it's essential to balance price and quality effectively. A lower-priced machine may seem like a good deal initially, but it can lead to long-term dissatisfaction if it fails to meet operational demands or compromises the quality of your product. High-quality machines often feature enhanced durability and better sealing capabilities, which can significantly influence customer experience. Investing in a reputable sealing machine could save you money in repairs and replacements down the line.

Tips for assessing the price versus quality include conducting thorough research on different sealing machines available in the market. Look for user reviews and ratings to gauge the performance and reliability of various models. Additionally, consider the materials and technology used in the machines; those built with higher-grade components tend to last longer and perform better. It's also a good idea to look for machines that offer warranties or guarantees, indicating manufacturers' confidence in their product's quality.

Upgrading your equipment is not merely an expense but rather an investment in your business's reputation and efficiency. Consider the long-term operational costs associated with cheaper machines, as downtime and product waste can quickly erode initial savings. By prioritizing quality while evaluating prices, you can ensure you select a machine that will support your business needs and foster customer loyalty.

When investing in a bubble tea sealing machine, maintenance and support are critical for ensuring the equipment's longevity and operational efficiency. Regular maintenance can significantly reduce downtime, which is essential for businesses that rely on high-volume production. According to industry research, properly maintained equipment can extend its lifespan by up to 30%, translating into substantial cost savings over time. Scheduled maintenance checks can address potential issues before they escalate, thereby enhancing productivity levels and maintaining quality.

Moreover, having reliable support from equipment suppliers is paramount. A recent survey indicated that 68% of bubble tea business owners prioritize after-sales support when selecting equipment, highlighting its importance in the decision-making process. Timely access to professional technicians and spare parts can minimize disruption and keep operations running smoothly. For bubble tea businesses aiming for long-term success, it is vital to ensure that their sealing machines come with robust maintenance plans and dedicated customer support, ultimately safeguarding their investment and maintaining customer satisfaction.