Leave Your Message

Are you looking for the right Can Sealer Machine? With the growing popularity of home canning, choosing the best model is crucial. Canning at home can save you money and help preserve food. But not all machines are created equal. With so many options, it can be overwhelming.

The right Can Sealer Machine can make a big difference in your experience. Some machines seal jars tightly, while others leave gaps. You want a machine that ensures freshness over time. Features like speed and ease of use matter, too. This doesn’t mean that choosing is easy.

Sometimes, the reviews are mixed. Some users praise a model, while others find it lacks durability. It's essential to read various opinions. Mistakes happen, even in research. You might find a machine that seems perfect only to be disappointed later. Taking the time to explore options will help you make an informed choice.

The can sealer machine market is evolving rapidly. In 2026, these machines are becoming more essential for food preservation. They help maintain freshness and improve shelf life. Many industries are adopting advanced sealing technology. This trend is driven by the demand for efficient packaging solutions.

Consumers are increasingly seeking user-friendly machines. The focus is on ease of use and maintenance. Many machines now offer automated features. Yet, some users find complex interfaces challenging. There’s a need for better instructions and support. Not every machine meets all users' needs effectively.

Sustainability is also a growing concern. Manufacturers are working towards eco-friendly materials. While this is promising, not all solutions are practical. Some designs lack durability, leading to frustrating experiences. It’s crucial for buyers to research thoroughly before purchasing. The right machine can make a significant difference in efficiency and quality.

| Model | Capacity (cans/min) | Power (W) | Weight (lbs) | Price ($) | Rating (out of 5) |

|---|---|---|---|---|---|

| Model A | 30 | 300 | 25 | 399 | 4.5 |

| Model B | 45 | 450 | 30 | 499 | 4.7 |

| Model C | 20 | 250 | 20 | 299 | 4.2 |

| Model D | 50 | 500 | 35 | 599 | 4.8 |

| Model E | 25 | 300 | 28 | 379 | 4.4 |

When selecting a can sealer machine in 2026, there are essential features to consider. Reliability is crucial. A robust machine should consistently produce well-sealed cans. Reports indicate that nearly 75% of users prioritize sealing consistency. A machine that fails to seal properly wastes materials and incurs costs.

Efficiency is another key feature. Many modern machines can seal around 25 cans per minute. This speed can significantly enhance production rates. However, some machines struggle with different can sizes. A flexible machine capable of handling various dimensions is invaluable. Moreover, ease of maintenance should not be overlooked. If a machine is complicated to clean, downtime increases.

User-friendly interfaces also promote productivity. Machines that offer intuitive controls reduce the learning curve. Research suggests that nearly 40% of operators prefer machines with simple layouts. While manual options can be less expensive, they may lack the convenience of automatic systems. Careful consideration of these features can lead to better investment decisions.

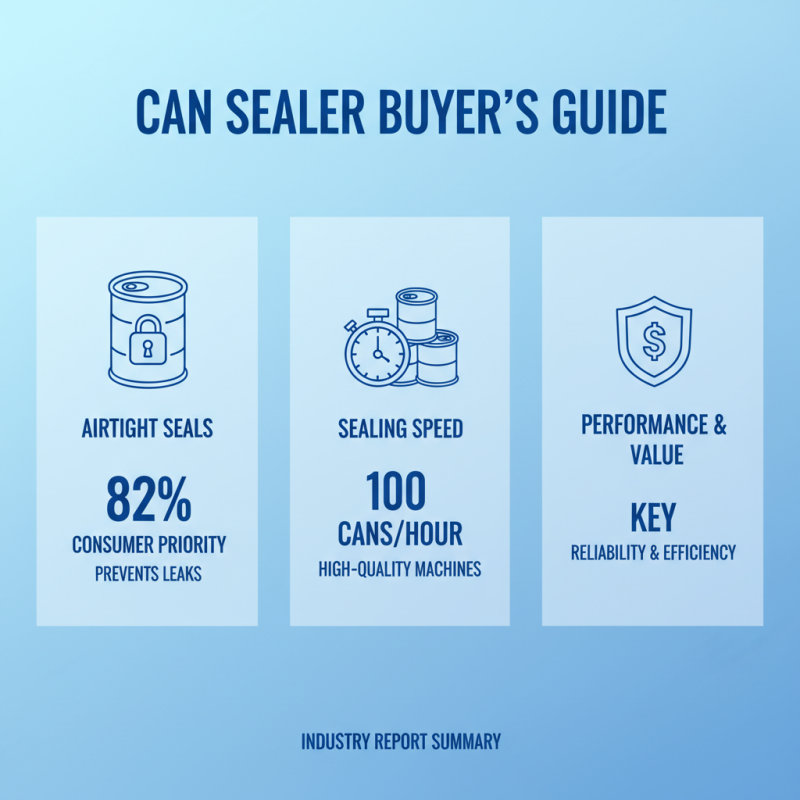

When selecting a can sealer machine, performance and value should be key considerations. According to industry reports, high-quality machines must consistently ensure airtight seals. A study found that 82% of consumers prioritize leak prevention. A machine's sealing speed also plays a critical role. Many models can seal up to 100 cans per hour, but this number drops significantly with low-quality machines.

Durability is another essential aspect. Machines made with rust-resistant materials last longer and offer better value. Research shows that machines with high-quality components can reduce maintenance costs by 30%. However, not every machine meets these standards. Some options may seem affordable but might need more frequent repairs. This can lead to more downtime and wasted resources.

Ease of use affects overall performance too. Complicated machines can frustrate users and slow down production. A survey indicated that 45% of users faced challenges with operation. It's crucial to balance advanced features with user-friendly designs. Machines that expend less energy and time are often worth the investment, even if the initial cost is higher. Evaluating these factors will lead to a more informed purchasing decision.

When exploring can sealers, user experience is crucial. Real-world testing reveals much about their effectiveness. Some models struggle with consistent sealing. Others perform well but have steep learning curves. Feedback often highlights issues like difficulty operating certain machines. Users frequently report frustration when seals fail during the process.

Some machines are reliable yet bulky, which can be inconvenient. Many users appreciate portability, but lightweight models can sacrifice build quality. Real-world tests show that while some machines seal cans quickly, they may not create airtight seals. Observing these outcomes helps potential buyers make informed choices. Always consider your specific needs before deciding.

In practical use, every can sealer has limitations. Some don’t handle different can sizes well. This can lead to wasted resources and time. Take note of users' experiences after prolonged use. Testing reveals that user comfort matters; poor ergonomics can lead to dissatisfaction. Overall, personal testing and feedback are essential when picking the right can sealer for your needs.

Maintaining a can sealer machine is essential for its longevity.

Regular cleaning is key. After each use, wipe the sealing area.

Remove any food residues. This prevents clogs and ensures efficient sealing.

Don’t neglect the gaskets. Inspect them monthly for wear and tear, replacing when necessary.

A small crack can ruin the seal.

Lubrication is another important step. Use appropriate oil on moving parts.

A little goes a long way. Over-lubrication can attract dust and grime. Keep an eye out for any unusual sounds.

Sudden changes might indicate a need for maintenance. It's easy to overlook small issues.

But addressing them early can prevent bigger problems later.

Storing the machine properly extends its lifespan. Avoid damp areas, as moisture can cause rust.

Cover the machine when not in use. This simple practice will help. However, it’s a good idea to check periodically

for any signs of rust or damage. Even the best machines need care to remain effective.

Regular attention makes a noticeable difference.