Leave Your Message

The packaging equipment industry is evolving rapidly. By 2025, the global market size is projected to reach $50 billion. This growth is driven by the need for efficiency and sustainability in production lines. Companies are seeking innovative solutions to enhance productivity and reduce waste.

In recent years, there has been a noticeable shift towards automated packaging equipment. Automated systems increase speed and accuracy, but they also require significant investment. However, businesses must consider the long-term savings and reduced labor costs. According to a 2022 report, automation can boost production efficiency by up to 25%.

Yet, not all packaging equipment solutions are perfect. Many businesses struggle with integrating new technologies into existing systems. Training staff and ensuring a smooth transition can be challenging. Failures in equipment can lead to production delays and increased costs. Nevertheless, the right packaging equipment can transform production, assisting companies in achieving their goals while adapting to market demands.

In 2026, packaging equipment is evolving rapidly. Trends are pushing for higher efficiency in production processes. Automation is becoming commonplace. Machines can now operate with minimal human intervention. This change cuts down labor costs and increases speed. However, complete reliance on technology raises concerns about job security.

Sustainability is also driving innovation. Many companies seek eco-friendly materials and processes. Machines that minimize waste or use recyclable materials are gaining traction. Yet, the challenge remains in balancing efficiency with environmental impact. Some systems may be too focused on speed, neglecting the importance of sustainable practices.

Flexibility is crucial in today's market. Equipment that adapts to different products without lengthy changeovers is in demand. However, not all manufacturers can invest in such versatile systems. Limited resources can restrict innovation. Companies must reflect on their capabilities and strive for improvement without sacrificing quality.

In 2026, packaging machines must adapt to evolving production needs. Efficient machines should combine speed, precision, and flexibility. High-performance models handle various materials with ease. Simplicity in operation is vital. Operators need less training time to manage complex systems.

Automation remains crucial for modern packaging. Machines equipped with advanced sensors can detect errors swiftly. This feature minimizes waste and ensures quality. High-speed integration enhances overall productivity but requires smooth collaboration with existing systems. Adjusting to these changes presents challenges. A vendor might not provide enough support.

Sustainability continues to impact packaging choices. Eco-friendly materials are gaining traction. Machines that accommodate these materials show innovation. However, the transition may expose inefficiencies. Regular maintenance is essential, yet it can be overlooked in fast-paced environments. The balance between efficiency and reliability must be carefully measured.

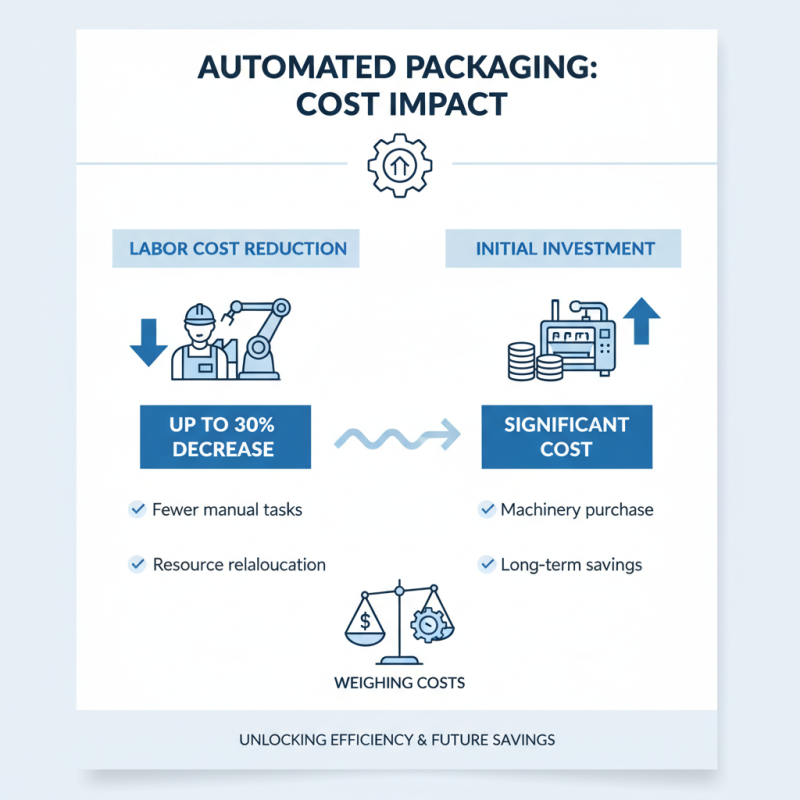

The impact of automated packaging on production costs is significant and multifaceted. Many industries see a reduction in labor costs when machinery takes over manual tasks. Estimates suggest that automation can decrease labor expenses by up to 30%. This allows companies to allocate resources to other areas of their operations. However, the initial investment in machinery can be daunting for some businesses. It's essential to consider the long-term savings when weighing these costs.

In addition to labor savings, there's an increase in speed and efficiency. Automated systems can operate continuously, reducing downtime. For example, a fully automated packaging line may handle thousands of units per hour. Mistakes and inconsistencies are also minimized, leading to fewer product recalls. Yet, companies must remain vigilant. Over-reliance on machinery can lead to complacency in workforce skills and knowledge. Those errors might not show up immediately but can turn into deeper issues if not addressed.

Another factor is maintenance costs. Automated systems require regular upkeep and occasional repairs, which can add to ongoing expenses. Businesses need a plan for training employees on maintenance practices. Otherwise, they risk incurring higher costs in the long run. Companies should embrace automation but remain adaptable. Balancing technology with skilled labor is crucial for sustainable production.

As companies strive for sustainability, eco-friendly packaging solutions have become crucial. More businesses are turning to biodegradable materials. These materials break down naturally and reduce landfill waste. A common option is plant-based plastics. They come from renewable resources, aiming to minimize environmental impact.

Innovations in packaging design also play a significant role. For instance, reusable packaging systems are gaining traction. They allow consumers to return packaging for refills, cutting down on single-use waste. Smart technologies can track how products are used. These insights help brands refine their packaging strategies.

However, challenges remain. Not all eco-friendly options are cost-effective. Companies may hesitate to invest in new materials due to higher prices. There’s also confusion around what truly qualifies as sustainable. Many claims lack transparency, leading to skepticism among consumers. This area still needs improvement. More clarity in regulations could support better choices for businesses and customers alike.

In the fast-paced world of production, efficiency is paramount. New packaging technologies can significantly boost productivity. By streamlining processes, they reduce waste and save time. Advanced automation, for example, allows for quicker adjustments in packaging lines. This can lead to fewer errors and enhanced precision. Implementing these systems requires careful planning and investment.

Evaluating ROI is crucial. Initial costs of new technology can be daunting. However, the long-term benefits often outweigh these expenses. Many firms struggle to track efficiency gains accurately. This makes justifying investments challenging. Periodic assessments and metrics are essential to measure real improvements in production. Without these efforts, businesses may overlook valuable insights. Striving for continuous enhancement is an ongoing journey.

Training staff on new equipment is equally important. Many employees resist changes. Their concerns should not be dismissed. Investing in proper training fosters acceptance and maximizes potential gains. Balancing technology and human skill is a delicate process. It often requires reflection and adaptation as companies navigate new landscapes in packaging.