Leave Your Message

In the vibrant world of bubble tea, the bubble tea sealing machine plays a crucial role. This device ensures that every cup is perfectly sealed. Renowned expert, Dr. Lisa Chen, once stated, “A good sealing machine enhances the customer experience.” This emphasizes the importance of quality equipment in the industry.

The bubble tea sealing machine functions by applying heat to seal the plastic film over the cup’s rim. Its design contributes to freshness, preventing spillage. Each seal preserves the flavors and textures that customers love. However, not all machines deliver the same quality. Some might seal poorly, leading to leaks or stale drinks.

Understanding how a bubble tea sealing machine operates can greatly impact beverage quality. Frequent maintenance and adjustments are necessary. Recognizing these details can be challenging. Yet, improving the sealing process can elevate a business. In this dynamic market, striving for perfection with sealing machines is essential for success.

A bubble tea sealing machine is an essential tool for bubble tea shops. It securely seals cups with a plastic film. This helps in keeping drinks fresh and free from spills. The machine uses heat or pressure to seal the film tightly over the cup. This simple process helps maintain bubble tea's unique texture and flavors.

Sealing machines come in various sizes. Some are compact, ideal for small shops, while others are larger for high-volume production. Operators place the cup in the machine, ensuring it is aligned correctly. After pressing the button, the machine does its job. Observing the sealing process can be fascinating, with steam and warmth at work. However, mistakes can happen if the cup is not centered properly.

Maintaining the machine is crucial. Neglecting it can lead to inefficiencies. For example, sealed cups may leak if the machine's heating element is worn. Regular cleaning helps avoid issues. Sometimes, the film may not stick well due to humidity. These factors must be monitored closely. The effectiveness of a bubble tea sealing machine significantly impacts customer satisfaction and product quality.

| Feature | Description | Benefits |

|---|---|---|

| Sealing Method | Heat sealing with plastic film | Ensures freshness and prevents spills |

| Speed | Seals up to 400 cups per hour | Increases efficiency in high-demand settings |

| Compatibility | Works with different cup sizes and materials | Versatile for various bubble tea products |

| Maintenance | Easy to clean and maintain | Reduces downtime and prolongs machine life |

| Control System | Digital control panel for settings | User-friendly and programmable options |

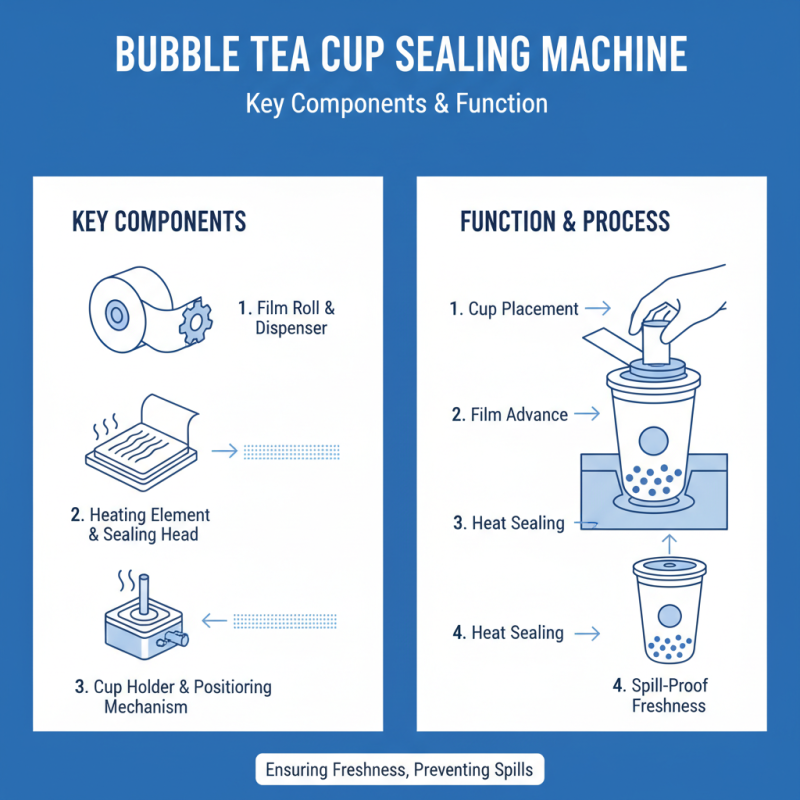

A bubble tea sealing machine plays a vital role in the bubble tea industry. Its primary purpose is to seal beverage cups, ensuring their freshness and preventing spills. Understanding the key components of this machine provides insight into its operation.

The heating element is crucial. It melts the sealing film, creating a tight seal over the cup's opening. This component needs careful attention. Overheating can lead to compromised seals. The pressure mechanism is equally important. It applies force to ensure the seal sticks properly. If not, customers might face messy experiences.

Other components include the conveyor belt and the control panel. The conveyor belt moves cups into the sealing area. A sticky situation arises if it malfunctions. The control panel allows users to set temperatures and timings. Sometimes, settings need tweaking for optimal results. Understanding these aspects can really enhance bubble tea production.

Bubble tea sealing machines are essential for cafés and beverage shops. They create a tight seal on cups, enhancing the bubble tea experience. This sealing process is simple yet effective. After filling the cup with tea and toppings, the machine uses heat to seal a plastic film over the opening. This prevents spills and keeps the drink fresh longer.

How does the machine operate? Typically, a sealing machine has a heating element and a holder. The cup is placed in the holder. Once positioned, the sealing film is applied. The heating element melts the film slightly, ensuring a strong bond. Machines can vary in size and capacity, but they all aim for efficiency. Proper calibration is important for consistent results.

Tips: Regular maintenance of the machine is crucial. Clogged seals can lead to messy results. Clean the sealing area frequently to avoid residue buildup. Experiment with sealing temperatures to find the best fit for different cup sizes and materials. Pay attention to the film type, as not all are compatible with every drink. Adjustments might be needed when switching between products.

Bubble tea sealing machines are essential for modern bubble tea shops. They provide a quick and efficient way to seal cups, preventing spills and ensuring freshness. Sealing machines create a tight barrier over the cup, maintaining the quality of beverages. This feature is especially important when serving drinks to go.

Using a sealing machine also enhances the customer experience. When customers see their drinks securely sealed, they feel more confident in the product. The visual appeal is undeniable. Plus, a well-sealed cup keeps drinks insulated for a longer time. This can improve customer satisfaction and increase repeat visits.

Tips: Regular maintenance of the sealing machine is vital. A clean machine ensures optimal performance and reduces the risk of contamination. Staff training is important, too. Proper sealing techniques can prevent leaks and preserve the drink's flavor. Remember, not all machines are the same. Take time to understand how your specific model works.

Maintaining a bubble tea sealing machine is crucial for ensuring optimal performance. Regular cleaning is a must. You should wipe down surfaces after each use. Sticky residue can build up quickly and negatively impact sealing quality. Use a soft cloth and a gentle cleaning solution. Pay special attention to the sealing area. A clean machine seals better.

Check the sealing film regularly. It should fit snugly around the cups. If it’s too loose or too tight, you might face issues. Replace the film when necessary. Frayed or damaged film can lead to spills. This creates mess and waste.

Also, inspect the machine for any signs of wear. Look for loose screws or worn-out parts. Noticing small issues early can save time and money. Listen for unusual noises during operation. They may signal a bigger problem. Regular maintenance can extend the life of your machine. However, if issues persist, consider professional help.