Leave Your Message

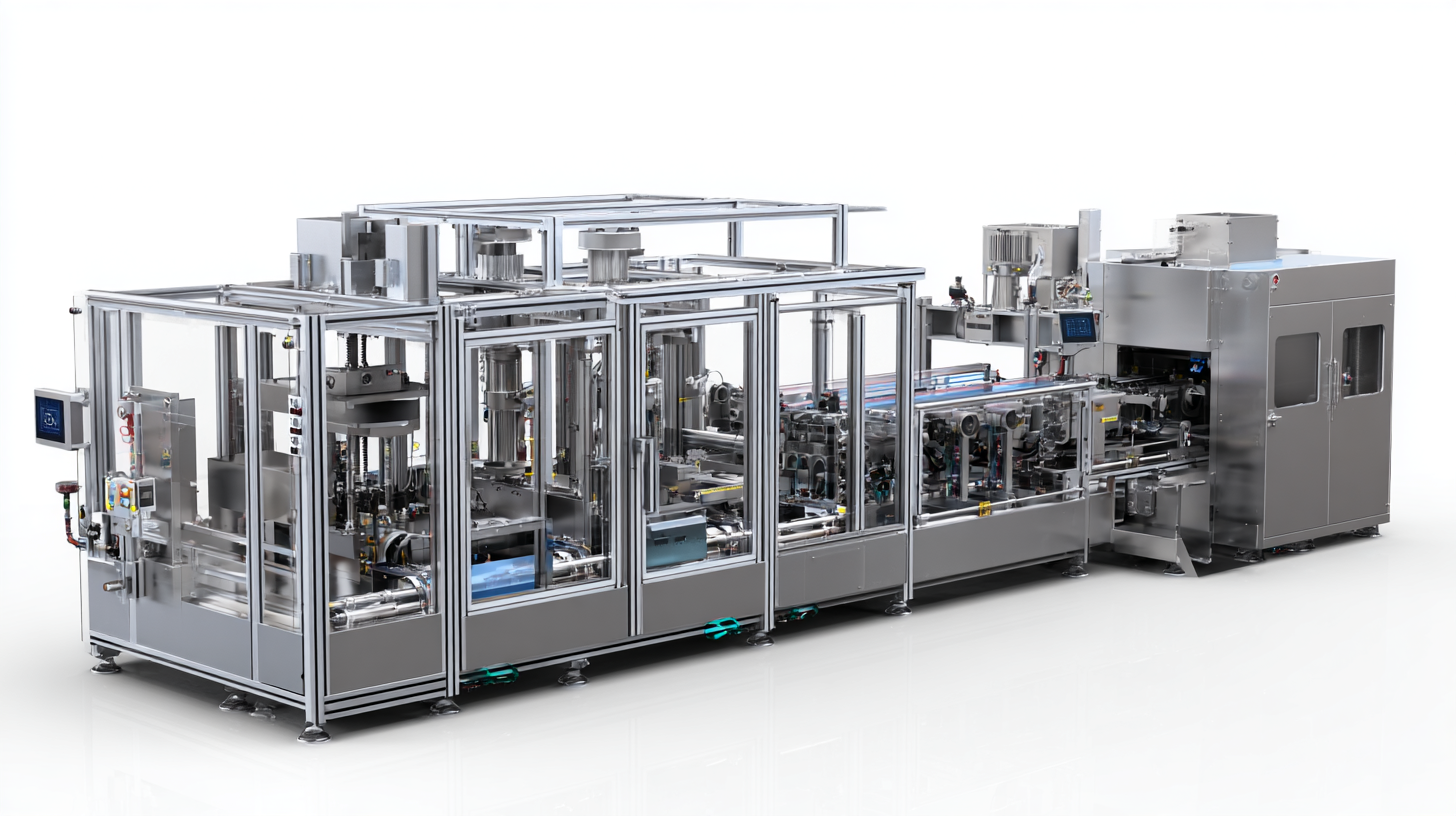

In today's fast-paced manufacturing landscape, selecting the right packing machine has become crucial for businesses aiming to enhance efficiency and maintain competitiveness. As we look toward the industry's future, particularly the technological trends projected for 2025, understanding the essential features and advantages of modern packing machines is vital. These machines not only streamline operations but also play a significant role in ensuring product quality and operational sustainability.

This blog will provide an essential checklist to guide you in choosing the best packing machine tailored to your specific business needs, keeping in mind the advancements and innovations that are shaping the industry. Whether you're in food packaging, pharmaceuticals, or consumer goods, the right packing machine can transform your workflow, boosting productivity and adaptability in an ever-evolving market.

When it comes to choosing the best packing machine for your business, understanding the key features is essential. A recent market analysis indicated that the global packing machine market is expected to reach $45 billion by 2027, growing at a CAGR of 3.5% from 2020. This growth underscores the importance of investing in the right equipment to enhance efficiency and productivity.

When it comes to selecting the ideal packing machine for your business, understanding the different types and their specific applications is crucial. Packing machines can be broadly categorized into several types—vacuum sealers, horizontal flow wrappers, and vertical form-fill-seal machines, among others. Each type serves distinct purposes depending on the nature of the products being packaged. For instance, vacuum sealers are perfect for perishable goods as they extend shelf life by removing air. In contrast, horizontal flow wrappers are ideal for packaging items like snacks and bakery products, providing a tight seal that maintains freshness.

Moreover, the choice of packing machine should align with the scale of your operations and production speed requirements. Vertical form-fill-seal machines are well-suited for high-volume production, efficiently packaging granules, powders, or liquids. For businesses involved in the packaging of fragile items, a custom machine often incorporated with protective features is necessary. Understanding the specific needs of your products will guide you to select a packing machine that not only enhances efficiency but also ensures product integrity.

When selecting the best packing machine for your business, key factors such as speed, efficiency, and size should be prioritized to optimize your operations. Speed, measured in packages per minute, can significantly impact your production flow. According to industry reports, businesses that upgrade to high-speed packing machines can see a 30-50% increase in throughput, ultimately improving their competitiveness in the supply chain.

Efficiency is not merely about speed; it also involves energy consumption and maintenance costs. A recent study highlighted that transitioning to energy-efficient packing machines can lead to a 20-30% reduction in operational costs. Moreover, the integration of machine learning techniques in packing systems allows for better inventory control, ensuring machines adjust to varying package sizes without compromising on sealing integrity or production speed.

Size also plays a critical role in the decision-making process. Machines that can accommodate a range of package sizes help in minimizing the need for multiple equipment, which can clutter the workspace and lead to inefficiencies. Advanced packing machines can adapt their configurations through adaptive algorithms, reflecting trends in various sectors, from food packaging to general goods. This adaptability not only conserves space but also streamlines the packing process, positioning businesses for a more sustainable future.

When it comes to investing in a packing machine for your business, conducting a thorough cost analysis is critical. According to a study by Freedonia Group, the U.S. packaging machinery market is projected to reach $10.9 billion by 2024, with a compound annual growth rate (CAGR) of 4.7%. This growth signifies the increasing importance of advanced packaging solutions in enhancing efficiency and reducing operational costs. Therefore, budgeting for a packing machine should not only encompass the initial purchase cost but also the extensive long-term benefits it can provide in terms of cost reduction and productivity.

When assembling your budget, consider factors such as machine capabilities, maintenance costs, and potential downtime. Research from PMMI highlights that equipment-related downtime can lead to losses of up to $50,000 per hour for large operations. Therefore, selecting a machine that minimizes maintenance needs and maximizes operational uptime is essential. Additionally, don't forget to account for training costs for your staff, as effective usage of the machinery can significantly impact your return on investment (ROI). Assessing these elements will ensure that you make a well-informed decision that aligns with your financial goals and operational requirements.

When investing in packing machinery for your business, ensuring its longevity is as crucial as selecting the right equipment. Maintenance and support play pivotal roles in prolonging the life of your packing machines. Regular maintenance schedules should be established to keep machinery running at optimal performance. It is essential to clean and inspect your packing equipment frequently, identifying any wear and tear before they escalate into costly repairs. Additionally, training staff on proper handling and operation minimizes the risk of damage, contributing significantly to the machine's durability.

Moreover, choosing a machine from a reputable manufacturer often comes with long-term support options that provide peace of mind. Look for companies that offer comprehensive service packages, including routine check-ups, quick repairs, and readily available spare parts. Establishing a good relationship with your equipment provider can lead to faster resolutions and tailored solutions that meet your specific needs. Investing time and resources into maintenance and support not only protects your initial investment but also enhances productivity, helping your business thrive in a competitive landscape.