Leave Your Message

In the ever-evolving world of packaging, the choice of a Heat Sealing Machine is crucial. Industry expert Jane Doe, a leading figure in packaging technology, once stated, "Investing in a Heat Sealing Machine transforms efficiency and quality." This statement resonates deeply in today's fast-paced market.

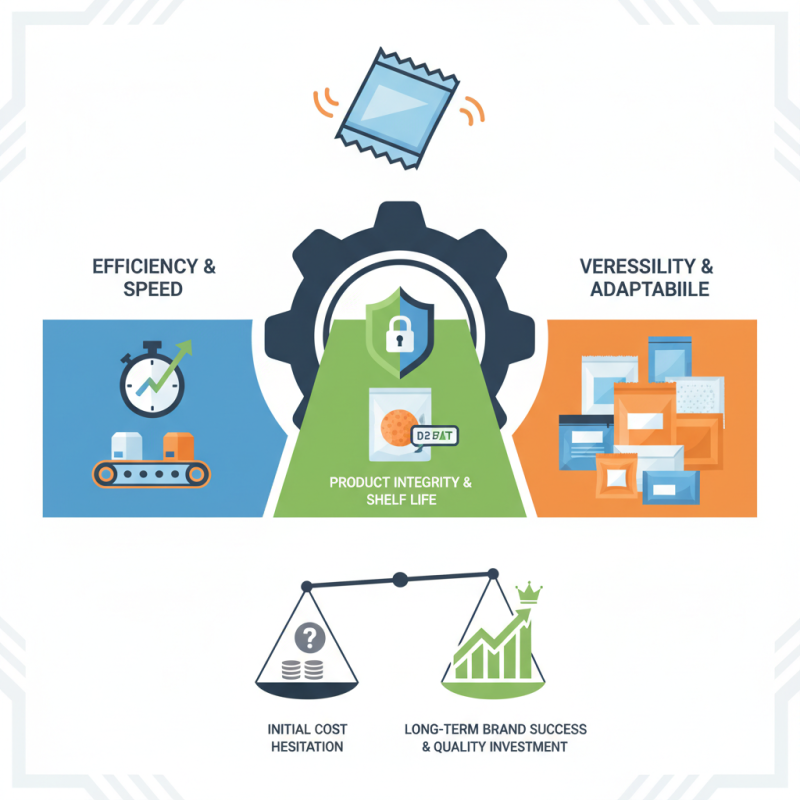

Heat sealing technology has become an industry standard for packaging. It not only ensures product integrity but also enhances shelf life. Many businesses overlook the importance of a reliable sealing solution. The process requires precision, and any lapse can lead to failures. A Heat Sealing Machine can help mitigate such risks.

Moreover, the versatility of these machines cannot be ignored. They cater to various materials and design specifications. Yet, some companies hesitate due to initial costs. Reflecting on this, companies must evaluate long-term benefits. Is it worth sacrificing quality for cheaper alternatives? Ultimately, investing in a Heat Sealing Machine could be the key to a brand's success.

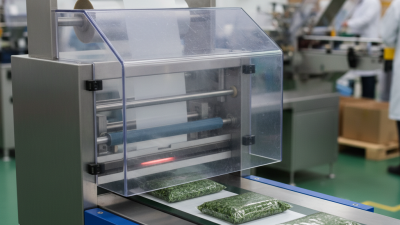

Heat sealing machines are essential in modern packaging. They provide a reliable solution for sealing various materials, ensuring product safety and integrity. According to a recent industry report, the heat sealing machine market is expected to grow by 5.8% annually. Such growth highlights their increasing popularity among manufacturers.

One major benefit of heat sealing is the versatility it offers. These machines can seal a wide range of materials, including plastic, paper, and aluminum. This adaptability allows businesses to use them for various products, from snacks to electronics. However, there's a learning curve. Improper settings can lead to weak seals, resulting in product spoilage.

Another significant advantage is efficiency. Heat sealing machines operate quickly, increasing production speed. In many cases, they can seal hundreds of packs in just an hour. However, some operators may overlook maintenance. Neglecting this can affect sealing quality. Regular checks are essential to ensure optimal operation and avoid unexpected downtime.

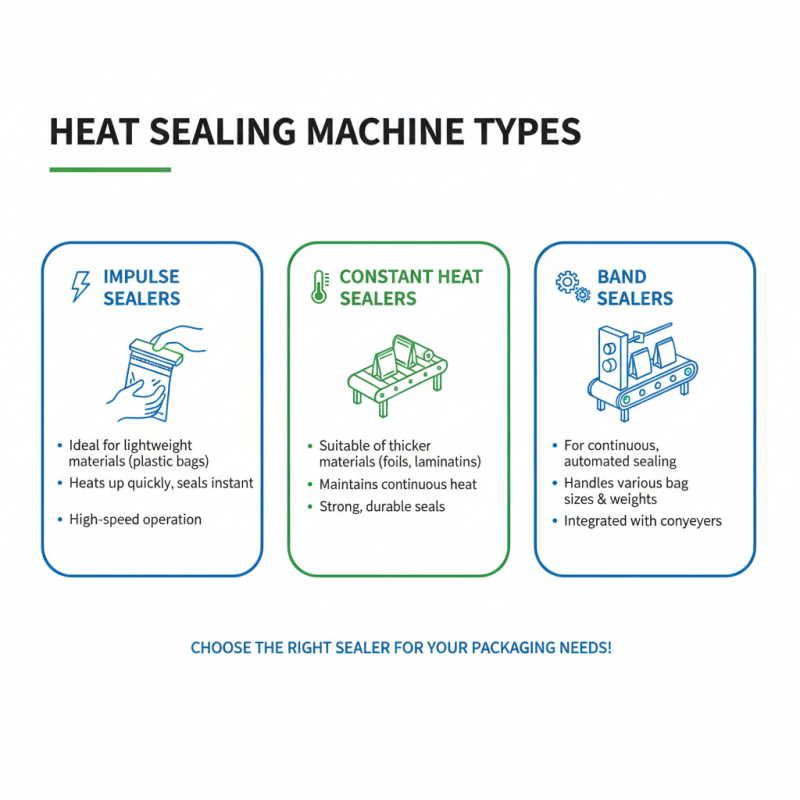

When considering heat sealing machines, it’s important to understand the various types available. There are several models designed for different packaging needs. For example, impulse sealers are ideal for lightweight materials, like plastic bags. They heat up quickly and seal in a matter of seconds. That's perfect for high-speed operations.

Another popular type is the continuous heat sealer. This machine works great for long runs of products. It can maintain a consistent sealing process. It’s more efficient for manufacturing environments. However, it requires a higher initial investment. That’s something to consider based on budget and production volume.

Tips: Always assess your packaging material before choosing a machine. Some materials may need special considerations. Test seals before full runs. An imperfect seal can lead to product spoilage or waste, which can be costly. Take time to train staff on using these machines. An untrained operator can slow down production and lead to errors.

When selecting a heat sealing machine, key features can greatly impact your packaging efficiency. One crucial aspect is sealing speed. According to industry reports, machines with higher sealing speeds can significantly reduce bottlenecks in production lines. For instance, equipment capable of sealing up to 30 packages per minute can enhance overall output. This is vital in sectors where time is money.

Another factor to consider is the versatility of sealing options. A good heat sealing machine should handle various materials, such as plastic, foil, and paper. Some machines can adjust temperatures and pressures, providing custom seals for different packaging types. This flexibility is highlighted in a study that found businesses using multi-material sealing machines reduced waste by 15%.

Lastly, user-friendly interfaces are essential. Operators should not struggle with complex settings. Machines with intuitive controls allow quick adjustments. Difficulty in operation can lead to errors, slowing the production process. In some surveys, 40% of workers reported training on complex machines contributed to inefficiencies. Thus, ease of operation plays a significant role in productivity and user satisfaction.

Heat sealing machines offer significant advantages in packaging. Their efficient sealing process can dramatically reduce costs. This equipment uses heat to bond materials. It’s a simple yet effective method. Businesses often see a quick return on investment. A well-made seal enhances product protection and shelf life. This is crucial for maintaining quality.

When considering a heat sealing machine, focus on your specific needs. Assess the materials you will use. Different machines work better with certain materials. Test samples before making a purchase. Additionally, think about maintenance. Regular upkeep can lower long-term expenses.

Tips: Invest in staff training. Properly trained employees will reduce errors. Errors can lead to wasted materials and increased costs. Also, consider the volume of production. A high-speed machine may be necessary for larger operations. But, sometimes a slower, more precise machine is more beneficial.

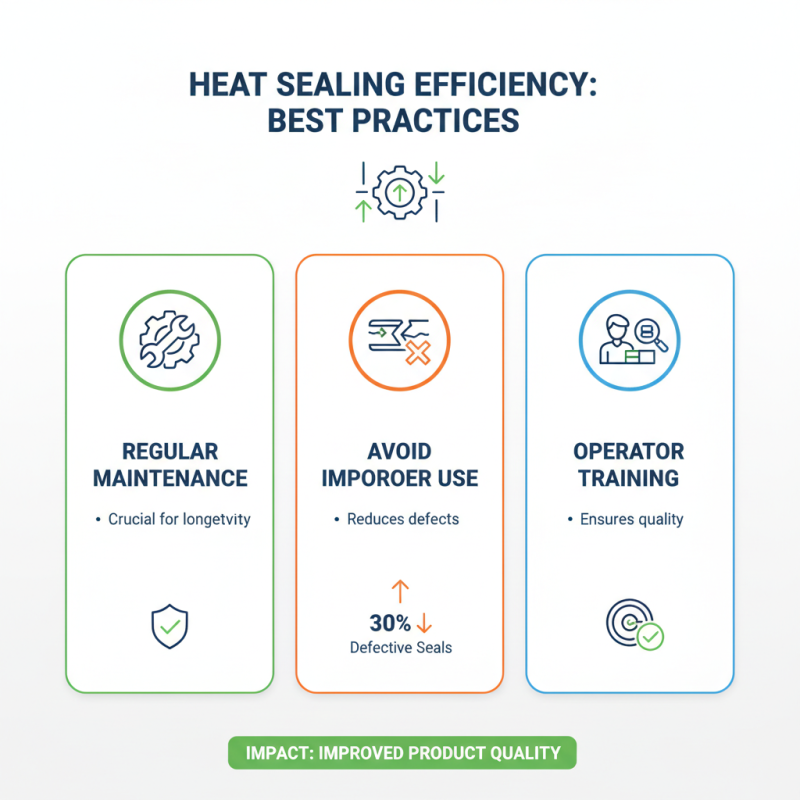

Heat sealing machines are essential in packaging. However, using them efficiently requires best practices. Regular maintenance is crucial. According to industry reports, improper use can lead to a 30% increase in defective seals. Many operators overlook this aspect, which can significantly impact product quality.

Cleaning the machine is one of the best practices. Dust and debris can accumulate, affecting performance. Studies show that 25% of machines fail due to a lack of cleaning. Operators should ensure the sealing area is free from contaminants. Routine inspections are also vital. Each part should be checked for wear. This simple step can prevent costly breakdowns.

Training staff is equally important. Experienced operators can identify issues early. Some companies report a reduction in errors by up to 40% with better training programs. However, many still operate under outdated practices. Regularly reviewing procedures can highlight areas for improvement. Operators must stay informed about new technologies and techniques.