Leave Your Message

Choosing the right Vacuum Packaging Machine for your business is a crucial decision that can significantly impact your operational efficiency and product quality. In today’s competitive market, having the appropriate packaging equipment not only helps in preserving the freshness and extending the shelf life of your products but also enhances your brand's appeal to customers. With a variety of models and features available, understanding your specific business needs, such as production volume, product type, and budget, is essential in making an informed choice. This guide aims to provide you with the necessary insights and considerations to help you navigate the selection process, ensuring you invest in a Vacuum Packaging Machine that aligns perfectly with your operational goals and enhances your overall packaging strategy. Making the right choice can lead to improved efficiency, reduced waste, and ultimately, greater customer satisfaction.

When selecting a vacuum packaging machine, it's crucial to first identify your specific business needs.

Consider the types of products you'll be packaging, whether it's food, medical supplies, or industrial items.

The features you require, such as the size of the bags, the volume of packaging needed daily, and the level of automation,

will depend on your industry. Your choice should align with both your product specifications and operational capacity.

When selecting a vacuum packaging machine, it's crucial to first identify your specific business needs.

Consider the types of products you'll be packaging, whether it's food, medical supplies, or industrial items.

The features you require, such as the size of the bags, the volume of packaging needed daily, and the level of automation,

will depend on your industry. Your choice should align with both your product specifications and operational capacity.

Tips:

Assess your product dimensions and weight to ensure the vacuum machine can accommodate your inventory.

Also, evaluate whether you need a chamber vacuum sealer for large quantities or a tabletop model for smaller batches.

Understanding the shelf life requirements of your products is essential, as different machines offer varying levels of vacuum quality and sealing capabilities.

Furthermore, consider your budget and maintenance needs. A higher upfront investment may lead to better durability

and efficiency in the long run. Look for equipment that offers ease of use and minimal upkeep while still meeting your production demands.

Investing in the right vacuum packaging machine not only enhances your packaging process but also boosts

overall product quality and shelf life.

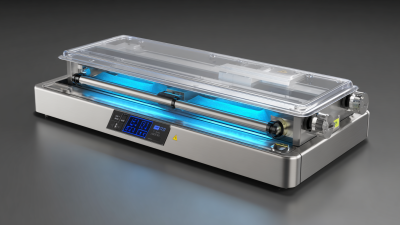

When selecting the right vacuum packaging machine for your business needs, it’s essential to understand the different types available in the market. Vacuum sealers primarily come in two categories: external suction sealers and chamber vacuum sealers. External suction sealers are generally more user-friendly and are suitable for home cooks or small-scale operations. They are perfect for sealing dry goods or marinated items but may struggle with liquids due to the nature of their design.

On the other hand, chamber vacuum sealers offer advanced features that cater to commercial applications. These machines remove air from both the bag and chamber, which allows for sealing liquids and sous vide preparations more effectively. They are particularly advantageous in industries like food processing, where preserving freshness is crucial.

Additionally, innovations such as high-speed wrapping capabilities and user-friendly interfaces make these machines appealing for businesses aiming to enhance productivity and reduce waste. As the vacuum packaging market continues to grow, understanding these distinct types will help you make an informed decision tailored to your specific needs.

When selecting a vacuum packaging machine for your business, several key features should be taken into consideration to ensure optimal performance. First and foremost, size matters. The dimensions of the machine should align with your production space and the volume of products you need to package. A compact model may suffice for small-scale operations, while larger businesses might require industrial-sized machines capable of handling greater output without compromising efficiency.

Seal quality is another critical aspect to evaluate. A superior vacuum packaging machine will create airtight seals, preventing air from entering the package, thus extending the shelf life of products. Look for machines with adjustable sealing settings, allowing for the packaging of various items, from delicate produce to robust meats. Additionally, speed is an important factor; a high-speed vacuum sealer can significantly increase productivity, enabling your business to meet demand quickly and effectively. Consider machines that offer a balance between speed and seal integrity to ensure quality remains uncompromised during high-volume runs.

| Feature | Option A | Option B | Option C |

|---|---|---|---|

| Size (L x W x H) | 18"x 10"x 8" | 24"x 14"x 10" | 30"x 16"x 12" |

| Seal Quality (Pressure) | 15 inHg | 20 inHg | 25 inHg |

| Speed (Bags per Hour) | 120 | 200 | 300 |

| Power Consumption (W) | 400 | 600 | 800 |

| Weight (lbs) | 25 | 45 | 75 |

When selecting a vacuum packaging machine for your business, one of the primary concerns is budget. It's essential to balance cost and quality to ensure that you get a machine that meets your operational needs without overspending. While cheaper models may seem attractive initially, they can often lead to higher long-term costs due to frequent maintenance issues or shorter lifespans. Investing in a reliable, quality machine can prevent these problems, ultimately saving your business money.

Another aspect to consider is the features that are most relevant to your operations. Higher-end machines may offer advanced functionality, such as adjustable sealing times and vacuum levels, which can enhance product preservation and packaging efficiency. However, it's crucial to assess whether these features align with your production scale and packaging requirements. By carefully evaluating your budget against the benefits of each machine, you can make an informed decision that supports both your financial and operational goals.

Maintaining and troubleshooting a vacuum packaging machine is crucial for maximizing its efficiency and extending the life of your food items. Regular maintenance involves cleaning the machine's components, such as the sealing bars and vacuum chamber, to prevent any residue build-up that could interfere with performance. It's important to inspect the seal quality periodically; if you notice any air leaks or uneven seals, this may indicate a need for recalibration or replacement of worn parts. Addressing these issues promptly ensures that your food remains sealed properly, thereby extending its shelf life and reducing waste.

In addition to routine maintenance, being knowledgeable about common troubleshooting techniques can save time and resources. For instance, if the machine fails to create a vacuum, checking for blockages in the intake or ensuring that the bags used are compatible can often resolve the issue. Furthermore, understanding the specific needs of the foods you are sealing—like moisture content or the types of materials used—can enhance the sealing process. By staying proactive with maintenance and learning to troubleshoot common problems, businesses can efficiently utilize vacuum packaging technology to preserve freshness and reduce food waste effectively.