Leave Your Message

Selecting the right heat sealing machine can be challenging. Many factors come into play. It's essential to understand your specific needs before making a decision.

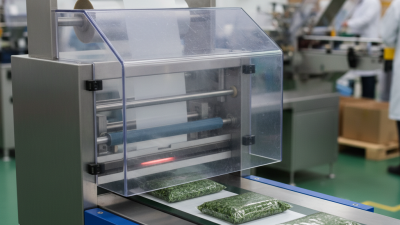

A heat sealing machine is crucial for businesses in packaging. This equipment ensures that products remain sealed and protected. However, not all machines are created equal. Some may lack the features necessary for your unique applications. Choosing the wrong one could lead to inefficiency and waste.

Consider the types of materials you'll be working with. Different machines excel with various packaging materials. It's also vital to assess the machine’s size and speed. A mismatched machine could hinder your operation. Take time to evaluate all options available. A well-informed choice can lead to better productivity. Don’t rush; reflect on your needs and the machine's capabilities.

When choosing a heat sealing machine, it's crucial to understand the different types available. There are several types to consider, each with its own unique features. For instance, impulse sealers work by applying heat for a short duration. They are ideal for sealing plastic bags quickly. However, they may not offer the strongest seals for thicker materials. Not everyone realizes this disadvantage, which can lead to product wastage.

Another type is continuous heat sealers. These machines are designed for higher production rates. They keep sealing without interruption, making them suitable for long runs of packaging. Yet, they require more space and careful setup. Misalignment during operation can result in poor quality seals. Users must pay attention to these details to avoid costly mistakes.

There's also the option of handheld sealers. These machines are portable and convenient for smaller tasks. However, they may lack the power needed for more demanding applications. Their variability in performance is common. Users might find themselves frustrated with inconsistent results if they don't have adequate training. Each type has its pros and cons, necessitating careful consideration of your specific sealing needs.

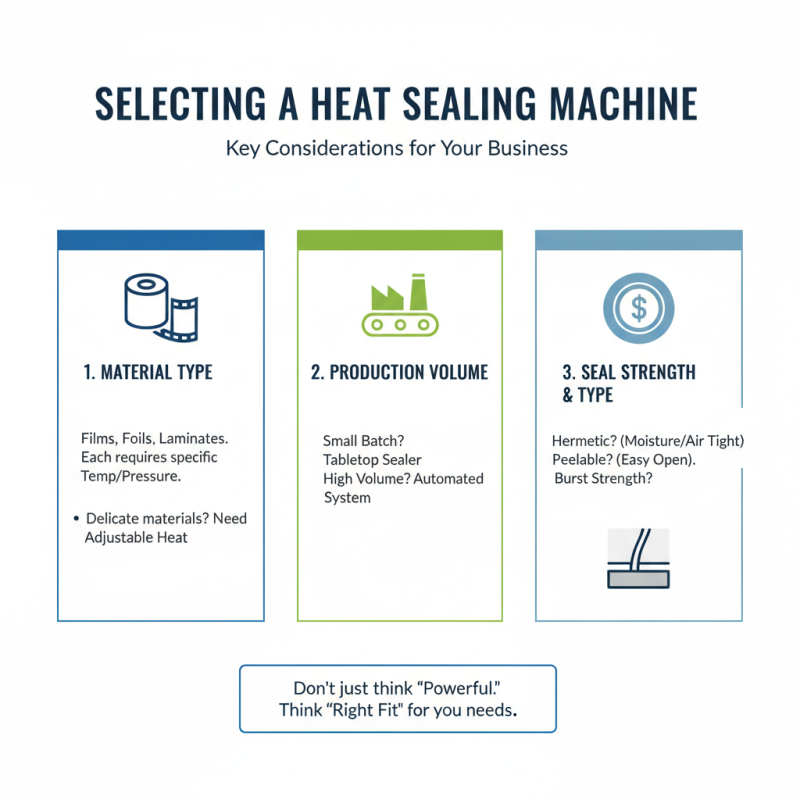

When selecting a heat sealing machine, it's vital to assess your specific sealing requirements. Think about the materials you frequently use. Different films and foils require different sealing temperatures and pressures. If you're working with delicate materials, a machine with adjustable heat settings is a must. Sometimes, you might think you need a robust, powerful machine, but a more gentle option could fit better.

Consider the sizes of your products. A larger machine might seem tempting, but not all operations need it. Packaging smaller items can be done effectively with a compact unit. Carrying out a test run is essential. You may discover that what works in theory isn’t practical in practice. The right machine can save time and materials, but if it doesn't meet your needs, it could lead to frequent adjustments and frustrations.

Check the sealing speed as well. Faster isn't always better. A quick seal could lead to poor quality if not monitored carefully. You might find a slower, more controlled process yields better results. Reflecting on your workflow can bring clarity to your decision. Not all machines offer the same efficiency. You might need to balance speed, quality, and ease of use based on your specific needs. Be open to considering aspects you might have overlooked at first.

When choosing a heat sealing machine, it’s crucial to consider specific features that align with your needs. One key aspect is the sealing mechanism. Machines can be impulse, continuous, or band sealers. Impulse sealers are great for low-volume tasks, sealing only when a pedal is pressed. Conversely, continuous sealers work well for high-volume production.

Temperature control is another vital feature. The right temperature ensures a secure seal without damaging materials. Research indicates that around 75% of production issues arise from improper sealing temperatures. Additionally, consider the machine’s portability. Some industries may require machines to be moved frequently. Compact designs can save space and facilitate ease of use.

Lastly, look into the warranty and support provided by the manufacturer. A robust warranty indicates quality. However, companies often fall short in after-sales support. This can lead to frustration during critical times. Choosing a machine with thorough support can mitigate potential downtime. Balancing these features based on your specific needs is essential for effective heat sealing operations.

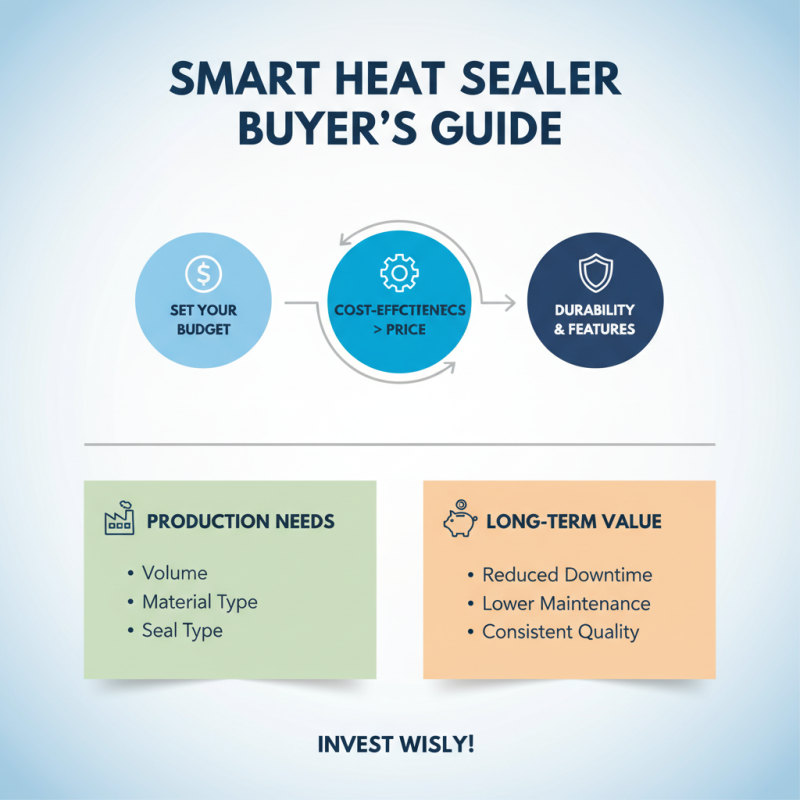

When selecting a heat sealing machine, budget is crucial. Determine how much you can spend. Remember that cost-effectiveness often outweighs the initial price. A higher-priced machine may offer better durability and features over time. Look for machines that fit your production needs and budget.

Tips: Always consider the long-term savings. While you might be tempted by low-cost options, they may lead to higher repair costs. Do your research on the average lifespan of different models.

Inexpensive machines might seem appealing. However, evaluate the potential for breakdowns and maintenance issues. A machine that is too cheap may not perform well under heavy use. This could lead to lost time and revenue. Assess whether spending a bit more could ultimately save you money.

When choosing a heat sealing machine, reliability and performance are crucial. Numerous brands and models flood the market, but not every option fits every need. Look for machines that offer consistent sealing without frequent calibration. A reliable machine minimizes downtime, which is vital in fast-paced environments.

Performance is often linked to the build quality and design. Consider machines with adjustable temperature settings. Some operate well at lower temperatures, reducing the risk of damaging sensitive materials. Investigate user reviews to identify models known for their long-lasting performance. However, be cautious—some machines may have glowing reviews but can disappoint in real-life use.

Finding the right machine may involve some trial and error. Smaller operations may benefit from budget-friendly models, but these may lack durability. Reflect on your specific needs before making a purchase. Remember, the right machine adds value to your process. Evaluate features critically and pay attention to details that influence usability.