Leave Your Message

In the bustling beverage industry, the art of crafting the perfect cup of boba tea extends beyond just ingredients and flavor; it also encompasses the crucial aspect of packaging. A key tool in this process is the Boba Sealing Machine, which ensures that each cup is securely sealed, preserving the freshness and flavor while enhancing the overall presentation. With a plethora of options available in the market, choosing the best Boba Sealing Machine for your business needs can seem overwhelming. Whether you're a small startup or an established enterprise, understanding the features, capacity, and efficiency of various sealing machines is vital for streamlining your operations. This ultimate guide will equip you with the necessary insights to make an informed decision, ensuring that your boba offerings not only taste fantastic but are also delivered in packaging that speaks to quality and professionalism.

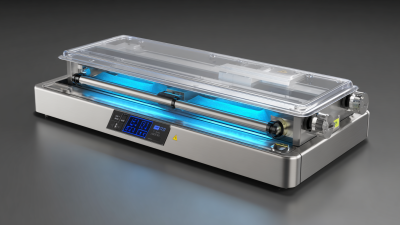

When selecting a boba sealing machine, it’s important to consider essential features that align with your business needs. One key feature is the sealing speed. A machine that can seal quickly and efficiently will help you keep up with high demand during peak hours. Look for machines that offer adjustable sealing speeds so you can optimize performance according to your volume needs.

Another crucial aspect is the machine's versatility. A good boba sealing machine should be compatible with various cup sizes and materials. This flexibility allows you to offer a broader range of beverages and ensures that you can adapt to changing customer preferences. Consider machines that come with customizable settings for different cup types to enhance your business offerings.

Lastly, durability is paramount. Investing in a robust machine that can withstand daily use will save you time and money in the long run. Tips for ensuring durability include choosing machines made from high-quality materials and checking for warranties. Regular maintenance is also essential for keeping the machine in top condition and prolonging its lifespan. By focusing on these essential features, you can choose a boba sealing machine that best supports your business needs.

When selecting the best boba sealing machine for your business needs, it’s essential to understand the different types available on the market. There are primarily three types of boba sealing machines: manual, semi-automatic, and fully automatic. Manual machines require the operator to place the cups and film sheets, sealing them by applying pressure. These are great for low-volume shops looking for budget-friendly options. Semi-automatic machines streamline the process by requiring less human interaction, making them suitable for moderate business volumes.

When selecting the best boba sealing machine for your business needs, it’s essential to understand the different types available on the market. There are primarily three types of boba sealing machines: manual, semi-automatic, and fully automatic. Manual machines require the operator to place the cups and film sheets, sealing them by applying pressure. These are great for low-volume shops looking for budget-friendly options. Semi-automatic machines streamline the process by requiring less human interaction, making them suitable for moderate business volumes.

Fully automatic boba sealing machines are the top choice for high-demand establishments. They handle the entire sealing process, from cup placement to sealing, with minimal human involvement. This efficiency not only saves time but also ensures consistency in production. When choosing a machine, consider your production volume, space, and budget to find the perfect fit for your business.

Tip: Always check for the machine's sealing speed and capacity. Knowing how many cups you can seal per hour can help you match the machinery to your expected customer flow. Additionally, investigate whether the machine accommodates different cup sizes, as flexibility can be beneficial in serving a wider range of customers.

When investing in a boba sealing machine for your business, comparing prices is essential to ensure you find the best value. A wide range of machines are available, so it’s crucial to analyze not only the upfront costs but also the long-term benefits they offer. Some machines might be cheaper initially but could lack durability or require frequent repairs, leading to higher costs over time. Assessing the total cost of ownership, including maintenance and operational efficiency, will help you make an informed decision.

Additionally, consider the features that come with different pricing tiers. While budget options may tempt you with their low prices, investing a bit more in a high-quality machine with advanced functionalities can enhance your customer experience and boost your business reputation. Look for machines that offer versatility, such as adjustable sealing options for different cup sizes and the ability to handle various cup materials. By prioritizing both quality and functionality in your comparison, you can ensure that your chosen boba sealing machine meets your operational requirements while providing excellent value for your investment.

When selecting a boba sealing machine for your business, particularly for high-volume production, several key considerations emerge that can significantly impact efficiency and profitability. First, it's essential to assess the machine's sealing speed. According to the National Restaurant Association, the demand for bubble tea has surged by 20% annually over the past five years, creating a pressing need for machines that can maintain high throughput to meet consumer demand. A machine capable of sealing 400 cups per hour can help maintain fast service during peak hours, ensuring customer satisfaction and repeat business.

Another crucial factor is the machine's reliability and ease of maintenance. A recent industry report highlighted that equipment downtime due to malfunctions can cost businesses up to $25,000 per year. Therefore, investing in a high-quality sealing machine with a user-friendly design and readily available maintenance support is vital. Additionally, consider the versatility of the machine. Many successful boba shops are expanding their offerings to include various beverage types, so selecting a machine that accommodates different cup sizes and materials can enhance operational flexibility and cater to a broader customer base.

| Feature | Consideration | Recommended Option |

|---|---|---|

| Sealing Speed | How many cups can be sealed per hour? | 500+ cups/hour |

| Machine Size | Will it fit in your available space? | Compact designs are preferable |

| Material Compatibility | What types of cups can be sealed? | Plastic and paper cups |

| Ease of Use | Is it user-friendly? | Intuitive controls are essential |

| Durability | How long will it last under regular use? | High-quality materials for prolonged use |

| Price | What is your budget? | $800 - $2000 based on features |

| Warranty | What kind of warranty is offered? | At least 1 year warranty |

When considering a boba sealing machine for your business, maintenance and support should be at the forefront of your decision-making process. The longevity of your boba sealer is crucial in ensuring operational efficiency and minimizing downtime. Industry reports indicate that regular maintenance can extend the lifespan of a sealing machine by up to 30%, which translates to significant savings on replacement costs. Machine manufacturers often provide comprehensive maintenance packages, including routine inspections and on-site repairs, which can be invaluable especially for businesses experiencing high volumes of output.

Furthermore, after-sales support is essential for troubleshooting and operational guidance. According to a recent survey, 70% of operators reported that having access to reliable technical support was a key factor in their satisfaction with equipment performance. This highlights the importance of choosing a supplier with a strong reputation for customer service. With the ongoing growth in the bubble tea market, evidenced by emerging brands and expanding chains, the right sealing machine—backed by robust maintenance and support—can provide a competitive edge in meeting consumer demands and maintaining product quality.