Leave Your Message

When it comes to streamlining production processes, selecting the right Liquid Filling Machine can significantly influence the efficiency and success of your business. As companies strive to enhance their operational capabilities, the importance of investing in suitable equipment becomes increasingly evident. A Liquid Filling Machine not only automates the filling process but also ensures accuracy, reduces waste, and increases overall productivity.

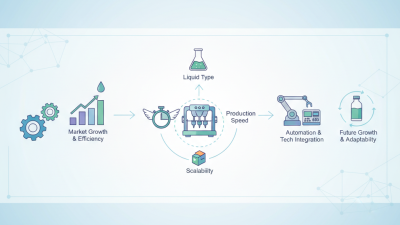

Understanding your specific business needs is crucial when choosing a Liquid Filling Machine. Various factors such as the type of liquid being processed, production volume, and packaging requirements must be considered. Additionally, features such as machine capacity, ease of use, and maintenance requirements play pivotal roles in optimal equipment selection. As the market offers a myriad of options, making an informed decision can help businesses achieve their operational goals while enhancing product quality and customer satisfaction.

When selecting the right liquid filling machine for your business, it’s essential to understand the various types available. Liquid filling machines generally fall into categories such as gravity fillers, piston fillers, and pump fillers.

Gravity fillers rely on the force of gravity to dispense liquid, making them ideal for thin and free-flowing liquids. Piston fillers, on the other hand, utilize a piston to draw and expel liquid, making them suitable for thicker fluids and products with varying viscosities. Pump fillers use a pump mechanism to control the flow of liquid, providing versatility for a wide range of liquid types.

Tips: When assessing the type of liquid filling machine you need, consider the viscosity of your product. For thicker liquids, a piston filler may be your best option, while gravity fillers might suffice for water-like substances. Additionally, evaluate the production speed requirements; some machines are better suited for high-volume outputs, while others excel in smaller runs with more precision.

Another key aspect to consider is the machine's compatibility with your packaging. Different filling machines may have varying filling nozzles and capabilities, which can affect how your products are presented.

It’s crucial to select a machine that aligns with your bottle or container designs to ensure a seamless filling process and maintain product integrity. Always test the machine with your specific liquid to confirm it meets both quality and operational standards.

When selecting a liquid filling machine for your business, the compatibility with your product characteristics is paramount.

Factors such as viscosity, temperature, and particle size significantly impact the type of machine that will function optimally.

For instance, a report by the Packaging Machinery Manufacturers Institute (PMMI) indicates that approximately 35% of machinery breakdowns are attributed to incompatibility with product viscosity, leading to operational inefficiencies.

Therefore, a thorough assessment of your product’s physical attributes is crucial in choosing a machine that aligns with your operational requirements.

Additionally, the container type and size play a vital role in ensuring compatibility. According to a recent market analysis, 70% of manufacturers prefer filling machines adaptable to various container shapes and sizes to maximize their production line's flexibility.

Whether dealing with glass bottles, plastic containers, or pouches, understanding the specific dimensions and material characteristics will guide you in selecting equipment that minimizes downtime and maximizes throughput.

Furthermore, consult industry standards and guidelines on ‘fill accuracy’ related to your specific product to ensure compliance and maintain product quality during the filling process.

These considerations are essential for streamlining production and enhancing your overall business efficiency.

When choosing a liquid filling machine, evaluating production speed and efficiency requirements is pivotal to align with your business goals. Understanding the volume of production your operation demands will guide you in selecting a machine with speed capabilities that meet your expectations. For instance, consider factors such as the number of bottles filled per minute, fill accuracy, and the time required for machine setup. Optimizing production speed helps minimize downtime and maximizes output, which is essential in a competitive market.

Efficiency is also critical when selecting a liquid filling machine. It encompasses not only how quickly the machine can fill containers but also how effectively it utilizes resources such as labor, energy, and materials. An efficient machine will streamline the process by reducing waste and ensuring consistent quality. This might involve looking at features like automated cleaning cycles, minimal part changes, and ease of operation. Ultimately, a well-chosen filling machine will not only meet your current production needs but also adapt to future demands, ensuring long-term viability for your business.

When considering a liquid filling machine for your business, it's crucial to balance the initial costs with the long-term investment potential. According to a report by Grand View Research, the global liquid filling machine market is expected to reach USD 5.4 billion by 2025, indicating a growing demand for efficient and versatile filling solutions. While the upfront costs for high-quality machines can be substantial—ranging from $10,000 to $100,000—these should be viewed through the lens of the return on investment (ROI) they can provide over time.

Tips: Always conduct a thorough cost-benefit analysis before making a purchase. Consider factors like machine durability, maintenance costs, and operational efficiency, as these will significantly impact your overall expenses in the long run.

Investing in a reliable liquid filling machine may mean higher initial costs, but the benefits often outweigh these expenses. A well-implemented filling system can enhance production speed by up to 25%, reduce waste, and minimize labor costs by automating repetitive tasks. According to industry studies, companies that invest in upgraded equipment typically see an ROI of over 150% within the first three years of operation.

Tips: Look for machines with flexible features that can adapt to different products and container types. This adaptability can help avoid future costs associated with replacing machines as your product line expands.

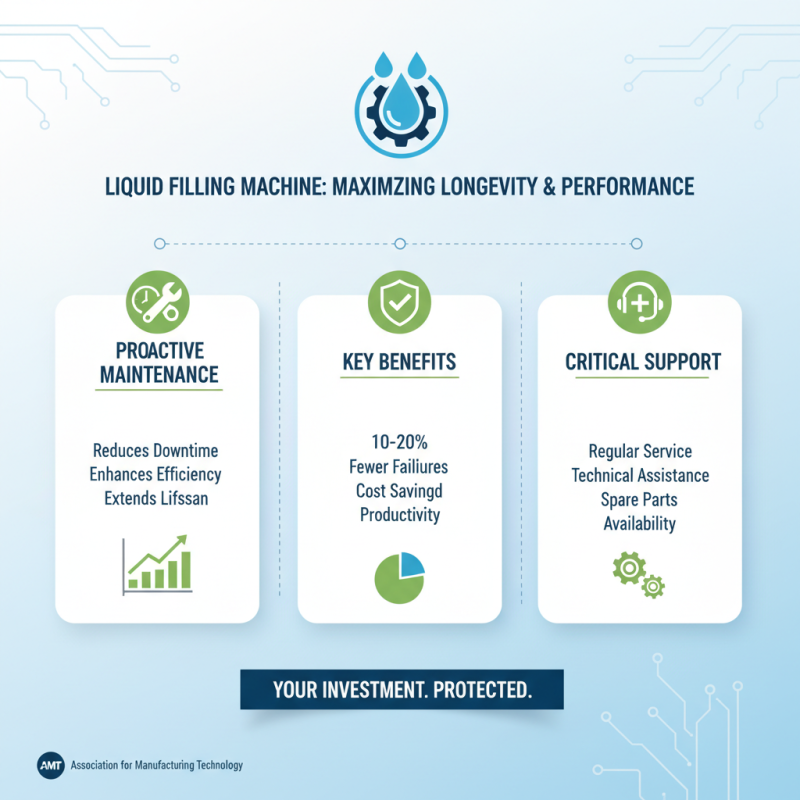

When selecting a liquid filling machine, maintenance and support are paramount to ensure the longevity and performance of your equipment. Regular maintenance not only enhances efficiency but also reduces downtime, which is critical for production schedules. According to a report from the Association for Manufacturing Technology, effective maintenance programs can lead to a 10-20% reduction in machine failures. Implementing a proactive maintenance strategy can extend the lifespan of your liquid filling machinery, ultimately saving costs and improving productivity.

Tips: Schedule routine inspections and adhere to the manufacturer’s recommended servicing intervals. Keeping detailed maintenance logs can also help identify recurring issues, allowing for more efficient troubleshooting and repair processes.

Moreover, consider the availability of technical support from the equipment supplier when making your choice. A reliable support system can greatly impact your operations, ensuring that any issues are promptly addressed. A survey by the National Association of Manufacturers shows that 76% of businesses prioritize after-sale service quality when selecting equipment. This suggests that beyond the purchase price, long-term support and maintenance capabilities should play a significant role in your decision-making process.

Tips: Before finalizing a machine purchase, gather information on the supplier’s customer service reputation and response times. During the selection process, ask about the typical turnaround times for parts and technical support to ensure minimal disruption to your operations.