Leave Your Message

In today's fast-paced commercial landscape, selecting the right packing machine is crucial for optimizing efficiency and ensuring product integrity. With an overwhelming array of options on the market, businesses face a daunting task when it comes to identifying the best machinery to suit their unique needs. This comprehensive comparison guide aims to demystify the selection process by providing critical insights into various types of packing machines, their features, and their applications. Whether you are a small startup or an established enterprise, understanding the nuances of packing machines will empower you to make informed decisions that enhance productivity, reduce waste, and ultimately drive profitability. Join us as we explore the key considerations and criteria to help you find the ideal packing machine that aligns with your business goals.

When choosing the best packing machine for your business, a fundamental step is to clearly identify your packaging needs. This includes analyzing the specific requirements of your products, the target market, and the volume of production. In the rapidly growing sterile medical packaging market, for instance, the demand for reliable, high-quality packaging solutions is driving significant industry investments. By 2032, the market is projected to expand considerably, showcasing various materials such as plastics, glass, and paper, which necessitates careful selection of machines capable of handling these differing materials efficiently.

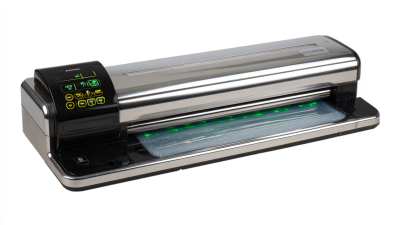

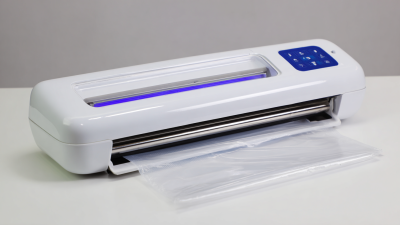

Furthermore, the wet process equipment market is expected to reach $2.9554 billion by 2033, highlighting the increasing need for innovative packaging technologies that cater to the demands of sectors like food and pharmaceuticals. Notably, the vacuum packaging machine segment is poised for substantial growth, with projections indicating revenues exceeding $4.9 billion by 2024 due to the food industry's push for extended shelf life. In this context, understanding the nuances of your packaging requirements will guide you in selecting a machine that not only meets your current needs but also aligns with future market trends.

When selecting a packing machine for your business, understanding the different types available is crucial. There are several categories of packing machines, including vertical form fill seal (VFFS), horizontal form fill seal (HFFS), and flow wrapping machines. According to a recent market report from Grand View Research, the global packaging machinery market is expected to grow at a compound annual growth rate (CAGR) of 6.0% from 2021 to 2028, emphasizing the rising demand for efficient packing solutions across various industries.

VFFS machines are particularly popular among manufacturers looking to package loose products like grains or snacks, due to their versatility and speed. Meanwhile, HFFS machines are favored in sectors that require horizontal packaging, such as the pharmaceutical or cosmetic industries. A study by MarketsandMarkets indicates that the demand for HFFS machines is projected to reach $14.6 billion by 2025. Additionally, flow wrapping machines are ideal for products that require a tight seal, often seen in food packaging. Each type of machine offers distinct advantages tailored to specific operational needs, making it essential for businesses to assess their unique packaging requirements before making a decision.

When it comes to selecting the right packing machine for your business, knowing what features to evaluate is crucial. First, consider the type of packaging that your products require. Different machines cater to various materials—be it bags, boxes, or shrink wrap. It's essential to choose a machine that aligns with your specific packaging needs to ensure optimal efficiency. Additionally, take into account the machine's speed and capacity. A higher throughput can significantly enhance productivity, making it vital to balance speed with the quality of packaging.

Another key feature to assess is the ease of operation and maintenance. A user-friendly interface will streamline the training process for your staff, minimizing downtime. Moreover, consider machines with automated features that reduce manual input, thereby cutting down labor costs. Durability and reliability are also significant; investing in a robust machine will lead to long-term savings by reducing repairs and replacements. Overall, by closely evaluating these features, you can make an informed decision to enhance your business’s packing processes effectively.

| Feature | Machine A | Machine B | Machine C |

|---|---|---|---|

| Speed (packages/min) | 30 | 45 | 25 |

| Package Size (L x W x H cm) | 10x5x5 | 15x10x10 | 12x8x6 |

| Power Consumption (kW) | 2.5 | 3.0 | 2.0 |

| Weight (kg) | 200 | 250 | 180 |

| Price ($) | 5000 | 7500 | 4500 |

When selecting a packing machine for your business, balancing cost and efficiency is crucial. Industry reports indicate that inefficient packaging processes can lead to increased operational costs, with some estimates suggesting that companies can lose up to 20% of profits due to suboptimal packing systems. For instance, a study by Smithers Pira highlights that automating packing operations can reduce labor costs by up to 30%, making it imperative for businesses to consider the long-term savings gained from optimal performance.

However, the initial investment in high-performance packing machines can be daunting for many small to mid-sized businesses. According to a recent report by ResearchAndMarkets, while basic machines can cost as little as $5,000, advanced automated systems may exceed $100,000. The key is to find a solution that fits your budget while enhancing efficiency. A thorough evaluation of your packing needs—including speed, flexibility, and compatibility with existing systems—will guide you in making an informed decision that aligns with both financial constraints and operational goals. Adopting a machine that balances these factors can lead to improved throughput and ultimately drive business growth.

Maintaining packing machinery is crucial for ensuring long-term operational efficiency and reducing unexpected downtime. A report by the Food Processing Suppliers Association (FPSA) highlights that regular maintenance can extend the lifespan of packing machines by up to 30%. Implementing a scheduled maintenance plan not only minimizes the risk of breakdowns but also optimizes performance, ensuring that machines operate within designated parameters.

Moreover, having robust support systems in place is essential for tackling emergencies when they arise. According to a recent study by Packaging World, companies that invest in comprehensive training programs for their operators report a 25% decrease in maintenance-related issues. This underlines the importance of continuous education and support, which can lead to a more knowledgeable workforce adept at handling machinery. By prioritizing maintenance and support, businesses can achieve greater efficiency, reduce costs associated with repairs, and ultimately enhance their production capabilities.