Leave Your Message

In the rapidly growing bubble tea industry, the right equipment is crucial for maintaining product quality and operational efficiency. One essential tool that has garnered attention is the Boba Sealing Machine, which plays a pivotal role in preserving the freshness and flavor of bubble tea by sealing cups securely. According to the recent "Bubble Tea Market Report" by IBISWorld, the bubble tea market has seen a staggering growth of over 8% annually, reflecting the increasing demand for this popular beverage. Choosing the right Boba Sealing Machine can ensure that your business not only meets customer satisfaction but also enhances productivity. With numerous options available in terms of size, capacity, and sealing speed, it's vital to navigate these choices carefully to align with your business needs and maximize profitability.

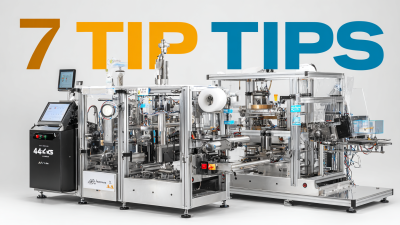

When it comes to choosing the right boba sealing machine for your business needs, understanding the different types available on the market is crucial. The primary categories of boba sealing machines include manual, semi-automatic, and fully automatic machines. Manual machines are ideal for small businesses or low-volume operations, allowing for hands-on control and flexibility. These machines typically require more labor but come at a lower initial cost, which can be appealing for startups.

On the other hand, semi-automatic and fully automatic machines cater to larger operations that prioritize speed and efficiency. Semi-automatic machines require some manual input but automate key processes, making them suitable for medium-sized businesses. Fully automatic machines, designed for high-volume production, streamline the entire sealing process, drastically reducing labor costs and increasing output. Each type has its own set of features, such as different sealing capacities and plate sizes, which need to be considered based on your specific production goals and space constraints.

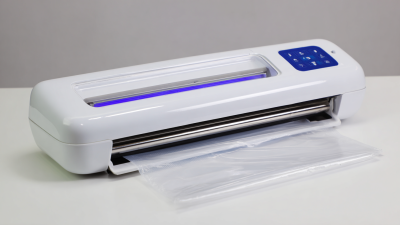

When selecting a boba sealing machine for your business, it's crucial to consider several key features that can significantly impact your operational efficiency. First and foremost, look for a machine with adjustable temperature settings. This flexibility allows you to accommodate various types of sealing films and beverages, ensuring that every cup is securely sealed without compromising quality. Additionally, machine speed and capacity are vital—opt for a model that can handle your expected volume during peak hours while maintaining a consistent sealing quality.

Another important factor is the ease of use and maintenance. A boba sealing machine with an intuitive interface will streamline operations for your staff, minimizing training time and errors. Furthermore, consider machines with easy-to-clean designs and accessible parts, as this will save you time and effort in the long run. Lastly, check for warranty and customer support options; a reliable machine backed by solid support can provide peace of mind and help you address any issues swiftly, ensuring your business runs smoothly.

When it comes to selecting the ideal boba sealing machine for your business, understanding the balance between cost and performance is crucial. A high initial investment in a top-tier machine may seem appealing, especially with features that promise speed and efficiency. However, it’s important to analyze whether those enhancements align with your business volume and customer needs. For small cafes or startups, a more affordable option that offers reliable basic functions might be sufficient to get started without breaking the bank.

On the other hand, businesses experiencing high demand should consider investing in machines that deliver superior performance, such as faster sealing times and improved durability. These machines often come with a higher price tag but can significantly reduce operational downtime and increase throughput. By closely assessing your budget against expected output, you can make an informed decision that maximizes profitability while minimizing potential losses from equipment failures or inefficiencies. Always consider the long-term benefits and maintenance costs to truly understand the value of your investment.

The automation of boba sealing machines is revolutionizing the way bubble tea businesses operate. As the demand for boba drinks continues to surge, efficient production methods become essential. Automation in sealing technology not only streamlines the process but also minimizes the risk of human error, ensuring that each cup of boba is sealed perfectly. This efficiency translates to faster service times, allowing businesses to handle higher volumes of orders during peak hours.

Moreover, incorporating advanced features such as programmable settings and automatic sealing adjustments can significantly enhance productivity. Businesses can customize their sealing operations according to different cup sizes and types without manual intervention, saving both time and labor costs. As the industry trend leans towards automation, entrepreneurs should consider investing in modern boba sealing machines that align with their operational needs. Ultimately, the right machine can bolster a company’s efficiency, contribute to customer satisfaction, and keep pace with an increasingly competitive market.

When investing in a boba sealing machine, proper maintenance is essential for maximizing your investment. Regular upkeep not only prolongs the lifespan of the machine but also ensures efficiency and quality in your bubble tea production. According to industry reports, routine maintenance can extend the lifespan of food equipment by up to 30%, saving businesses significant replacement costs in the long run. Simple practices such as cleaning the sealing plates, checking for wear and tear, and ensuring proper lubrication can prevent more extensive repairs and downtime.

Another critical aspect of maintenance is understanding the machine's operational nuances. Studies indicate that machines that are calibrated correctly perform up to 20% more efficiently, producing better quality seals that keep beverages fresher for longer. Regularly inspecting for any misalignments or mechanical issues is crucial. Additionally, training staff on the correct operating procedures can minimize misuse and prolong the machine's functionality. By prioritizing maintenance and proper usage, businesses can maximize their investment and enhance their service quality in a competitive market.