Leave Your Message

Choosing the right Label Printing Machine for your business needs is a crucial decision that can significantly impact your operational efficiency and branding efforts. With a variety of options available, ranging from compact, desktop models to large industrial machines, it can be overwhelming to determine which one best fits your specific requirements. Understanding the features, capabilities, and costs associated with different label printing machines is essential for making an informed choice.

This guide will explore key factors to consider, including print speed, resolution, label material compatibility, and scalability for future growth. By taking the time to evaluate your business's unique demands, you can select a label printing machine that will not only improve productivity but also enhance your brand image and customer satisfaction.

When selecting a label printing machine for your business, it is crucial to understand your specific printing requirements and objectives. Start by evaluating the types of labels you need to produce. Considerations such as size, material, and adhesive type will significantly impact your choice. For instance, if your products require durable labels that can withstand harsh conditions, you may need a machine that can handle thicker materials and higher-quality ink. Identifying the application of your labels—whether for retail, shipping, or branding—will also guide you in choosing the right machine.

Next, think about your printing volume and frequency. Are you printing labels in large batches or only as needed? High-volume operations might benefit from more industrial machines that can print quickly and efficiently, while smaller businesses might find that desktop printers suit their needs perfectly, allowing for flexibility. Additionally, assess the ease of use and maintenance of the machine, as these factors will influence your productivity. Collectively, these considerations will help you set clear objectives for your label printing needs, ensuring you invest in a machine that aligns perfectly with your business goals.

When choosing a label printing machine for your business needs, it’s essential to evaluate the various types available in the market. According to a report by Smithers Pira, the global label printing market is projected to reach $48 billion by 2024, driven by the increasing demand for custom packaging and the rise of e-commerce. Businesses must align their printing technology with these trends to maintain a competitive edge.

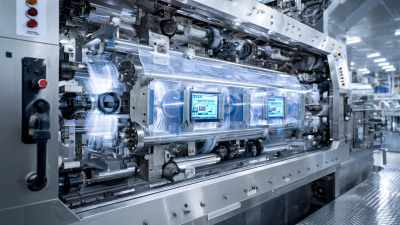

Different types of label printing machines, including thermal transfer, direct thermal, and inkjet printers, each have their advantages depending on the application. Thermal transfer printers, for instance, are known for producing durable labels suitable for harsh environments, with a lifespan of up to 5 years, as highlighted in a recent industry analysis. On the other hand, inkjet printers offer exceptional color quality and flexibility, making them ideal for short-run jobs. Understanding these distinctions can greatly influence production efficiency and cost-effectiveness for a business, ensuring that the chosen machine aligns with operational demands and product specifications.

When selecting the right label printing machine for your business needs, it's crucial to consider key features that align with your operational requirements. According to a report by Smithers Pira, the global label market is set to exceed $50 billion by 2025, emphasizing the need for efficient and versatile labeling solutions. Look for machines that offer high-speed printing and consistent quality, ensuring that you can meet increasing demand without compromising on precision.

One important feature to consider is the printing method. Thermal transfer printers are ideal for durable labels, while direct thermal printers may be more suitable for shorter runs. Furthermore, assess the compatibility with various label materials, as this flexibility can significantly impact your production process. As reported by the Freedonia Group, the demand for digital label printing is expected to grow substantially, making machines that support digital workflows increasingly valuable.

Tip: Before making a purchase, evaluate the machine's ease of use and maintenance requirements. A user-friendly interface can save time during training and operation, while machines with lower maintenance needs can reduce long-term costs. Additionally, consider the support and resources available from manufacturers, as having access to technical assistance can streamline your workflow when challenges arise.

When considering the right label printing machine for your business, budget plays a crucial role in your decision-making process. The label printer market is expected to reach a value of approximately $684 million by 2030, with a compound annual growth rate (CAGR) of 6.2% from 2024 to 2030. This growth reflects the increasing demand for high-quality labels that enhance business operational efficiency, from shipping labels to retail barcodes.

In the small business sector, it's essential to recognize the balance between cost and functionality. For instance, the latest thermal printers are designed to produce clear, high-quality labels swiftly, which can significantly streamline your inventory management and sales processes. With options tailored to various business needs, small enterprises can find solutions that fit comfortably within tighter budgets while still benefiting from advanced features. Investing in a reliable label printing machine is not just about upfront costs; it's about selecting equipment that will yield a strong return on investment through improved productivity and reduced operational hassles.

When selecting a label printing machine, considering scalability and upgrade options is crucial for future-proofing your business. As your company grows, your labeling needs will likely evolve. A machine that accommodates a variety of label sizes and materials can save you from having to invest in new equipment as your demands shift. Look for models that support modular upgrades or enhancements—such as additional print heads or cutting capabilities—that allow you to expand your functionality without overhauling your entire system.

Additionally, consider the software compatibility of your label printing machine. The right software can streamline your design process and provide greater flexibility in label production. Opt for solutions that offer regular updates and new features, enabling your business to remain competitive in an ever-changing market. Investing in a label printing machine that is inherently upgradeable ensures you can adapt to new trends and technologies, securing long-term efficiency and effectiveness in your label production endeavors.

| Feature | Entry Level | Mid-Range | High-End |

|---|---|---|---|

| Print Resolution (dpi) | 300 dpi | 600 dpi | 1200 dpi |

| Print Speed (ipm) | 10 ipm | 30 ipm | 60 ipm |

| Media Width (inches) | 2-4 inches | 2-8 inches | 2-12 inches |

| Connectivity Options | USB | USB, Ethernet | USB, Ethernet, Wi-Fi |

| Scalability Features | Limited | Moderate | High |

| Upgradeability | None | Possible | Extensive |