Leave Your Message

Choosing the right packing machine for your business needs is a crucial decision that can significantly impact efficiency, product quality, and overall operational costs. With a multitude of options available on the market, it can be overwhelming to determine which packing machine will best suit your specific requirements. This guide will explore essential tips and factors to consider when selecting a packing machine, ensuring that your investment aligns with your unique business objectives. From understanding the various types of packing machines and their functionalities to evaluating your production volume and product specifications, we will provide you with valuable insights to help you make an informed choice. Whether you are a small business or an established enterprise, selecting the right packing machine is vital for streamlining your packaging process and enhancing your competitive edge.

When choosing the right packing machine for your business, it's crucial to understand your packaging requirements and objectives. The packaging machinery industry focuses on automating and enhancing packaging processes across various sectors, including food, pharmaceuticals, and consumer goods. As sustainability becomes an increasingly significant factor, businesses must consider their environmental impact while meeting customer expectations for efficiency and effectiveness.

Tips: First, assess your business scale and product types. Different machines cater to specific needs such as filling, sealing, labeling, or packing. Secondly, consider the market trends toward sustainable packaging; this includes machines designed to use biodegradable or recycled materials, which can enhance your brand image and meet consumer demand.

Additionally, it's important to evaluate the technological advancements in the packing machinery market. Selecting equipment that integrates with e-commerce platforms can provide further efficiency in processing orders, especially in a market projected to grow significantly in the coming years. By aligning your machine choice with your business objectives and market trends, you can ensure a robust and forward-thinking packaging operation.

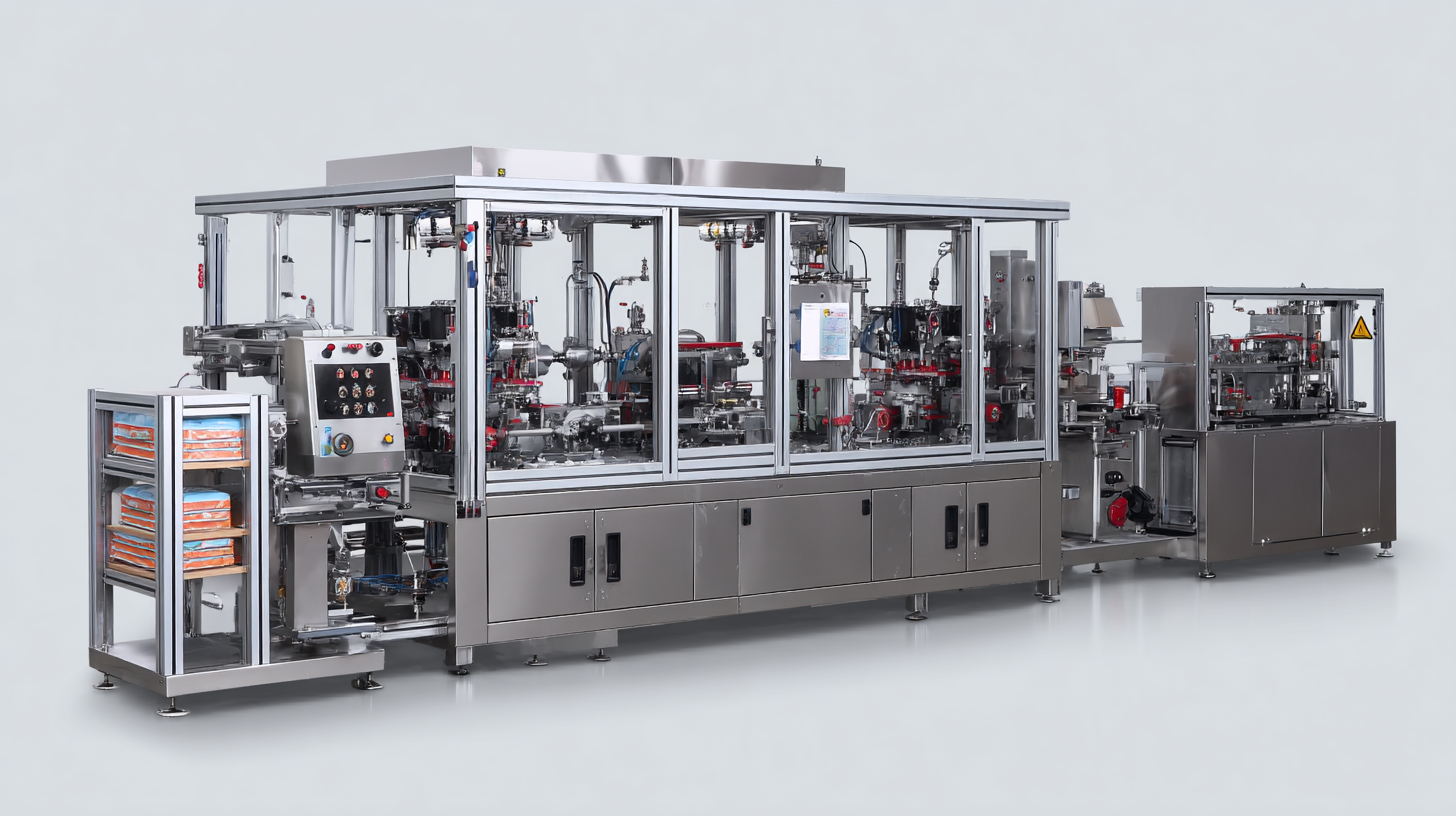

When evaluating different types of packing machines available, it's essential to consider the specific requirements of your business. Different industries may require unique packing solutions, so assessing factors such as product size, weight, and fragility is crucial. For example, lighter products may benefit from a vertical form-fill-seal machine, while heavy-duty items might require a strapping machine. Researching the capabilities of each type can help you make an informed decision.

Tip: Always consider the scalability of the packing machine. As your business grows, you may need to increase production capacity. Investing in a machine that offers upgrade options or higher efficiency can save you time and money in the long run.

Additionally, the type of packing material you intend to use can influence your choice. Some packing machines are designed for specific materials, whether plastic, paper, or eco-friendly alternatives. Understanding the machine's compatibility with your material needs can ensure a smoother workflow.

Tip: Look for machines that offer flexibility in packing styles and sizes, allowing for adjustments as your product lineup evolves. This adaptability can significantly enhance your operational efficiency.

When selecting a packing machine for your business, it's crucial to consider several key features that can significantly impact your operational efficiency. According to a report from Grand View Research, the global packaging machinery market is expected to reach $55 billion by 2027, highlighting the increasing reliance on efficient packing solutions across various industries. One of the primary features to evaluate is the machine's speed and capacity, as this can directly influence your production output. For instance, a machine with a speed of 50 packages per minute can significantly enhance productivity compared to slower models.

Another critical aspect is the machine's versatility. Many businesses require packing machines that can handle different sizes and types of products. Research from Smithers Pira indicates that versatile packing machines that can easily switch between automatic and semi-automatic operations are in high demand, as they adapt to changing market needs more efficiently. Additionally, consider the technological aspects like automation and ease of use. Advanced packing machines equipped with smart technology not only improve accuracy but also reduce labor costs, marking them as a wise investment for businesses looking to enhance their packing processes.

When considering the acquisition of a packing machine, budgeting and cost analysis are critical steps that can significantly impact your business's bottom line. According to a recent report by Technavio, the global packaging machinery market is expected to grow by over $5 billion between 2021 and 2025, driven by rising consumer demand for packaged goods. This growth underlines the importance of not only selecting the right machine for your operational needs but also understanding the associated costs.

Initial investment is just one aspect of the total cost of ownership. A comprehensive cost analysis should also include maintenance, training, and operational costs. For instance, a study by PMMI found that businesses can spend up to 20% of the initial machinery cost on maintenance over the first five years of operation. As such, it is vital to assess the longevity and reliability of the machine, as well as warranty options that can mitigate future costs. Furthermore, consider how automation can reduce labor expenses; businesses that implement automated packing solutions can achieve a reduction in labor costs by up to 30% per unit produced, according to a survey conducted by the International Society of Automation. By carefully evaluating these factors, you can make a more informed decision that aligns with your budget and operational goals.

When choosing the right packing machine for your business, it is essential to assess supplier reputation and after-sales support thoroughly. Supplier reputation plays a crucial role in ensuring that you partner with a reliable company that delivers quality products. Researching customer reviews, industry standards, and any certifications can help you gauge a supplier's credibility. A supplier with a solid reputation is likely to provide superior products and services, reducing the risks associated with your investment.

After-sales support is another critical component to consider. A robust after-sales service can significantly impact the operational efficiency of your packing machine. Look for suppliers that offer comprehensive training, timely maintenance, and quick response times for any issues that may arise. In today's fast-paced market, where supply chain dynamics are constantly shifting, having a partner that prioritizes after-sales support can help ensure your business runs smoothly and maintains its competitive edge. Effective supplier relationships, bolstered by strong after-sales support, can ultimately lead to enhanced productivity and reduced operational costs.