Leave Your Message

In the ever-evolving landscape of food preservation and packaging, Vacuum Sealing Machines have emerged as indispensable tools for both commercial and domestic use. The ability to extend shelf life, reduce food waste, and maintain flavor integrity makes vacuum sealing a game-changer in the food industry. However, procurement of these machines can often be a complex and daunting task, especially with the myriad of brands, specifications, and technologies available. This blog post will explore seven effective tips designed to enhance your procurement strategy for Vacuum Sealing Machines, ensuring that you make informed decisions that align with your operational needs and budget constraints. From assessing vendor reliability to understanding the latest innovations, these insights will empower you to invest wisely in equipment that not only meets but exceeds your expectations in performance and durability.

Vacuum sealing machines have become essential in procurement strategies, especially for businesses dealing with perishable goods. These machines significantly extend the shelf life of products by removing air from packaging, thereby preventing spoilage and reducing waste. This is particularly critical in industries such as food processing, biomedical, and logistics, where timely delivery of fresh products is paramount. By integrating vacuum sealing into their procurement strategy, companies can enhance product safety, improve efficiency, and optimize inventory management.

Moreover, understanding the vital role of vacuum sealing machines allows procurement managers to focus on quality and reliability when sourcing. A well-researched procurement strategy can lead to cost savings in the long run, as quality machines reduce the likelihood of product damage and losses. Emphasizing vacuum sealing can also facilitate better supplier relationships, fostering trust and collaboration with vendors who share an understanding of the importance of maintaining product integrity. This results in a streamlined supply chain, ultimately benefiting the entire organization.

| Tip | Description | Benefits |

|---|---|---|

| 1. Assess Your Needs | Evaluate the specific requirements for vacuum sealing based on your business type. | Ensures you select a machine that fits your operational demands. |

| 2. Research Product Features | Look for essential features such as adjustable settings and sealing options. | Maximizes efficiency and versatility in sealing different products. |

| 3. Compare Pricing | Collect quotes from multiple suppliers to find competitive pricing. | Helps optimize budget without compromising quality. |

| 4. Read Reviews | Check user reviews and ratings to gauge product reliability. | Provides insights into performance and customer satisfaction. |

| 5. Consider Warranty and Support | Examine the warranty period and available customer support. | Ensures peace of mind and assistance if issues arise. |

| 6. Evaluate Durability | Check construction materials and build quality for long-term use. | Reduces the need for replacements and maintenance costs. |

| 7. Test Before Purchasing | If possible, demo the vacuum sealing machine to ensure it meets your standards. | Confirms that the equipment works properly in your environment. |

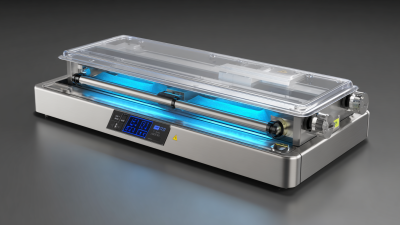

When purchasing vacuum sealers, understanding the critical features can greatly influence the efficiency and effectiveness of your procurement strategy. According to a recent report by Market Research Future, the global vacuum packaging market is estimated to reach $44 billion by 2025, highlighting the growing importance of this technology in various industries. With this increase, it is crucial to identify key features that distinguish high-quality machines from the rest.

Tip 1: Consider the vacuum pressure level. Higher vacuum pressure can significantly extend shelf life, especially in the food industry, where studies have shown that properly vacuum-sealed food can last up to five times longer compared to traditional storage methods. Look for machines that offer adjustable pressure settings to cater to different types of products.

Tip 2: Examine the sealing strip. A longer sealing strip generally allows for larger bags and more versatility in packaging. According to industry standards, a high-quality sealing strip should reach temperatures between 140°F and 160°F to ensure a strong seal.

In addition, Tip 3: assess the ease of use and maintenance. Features such as automatic vacuum sealing and easy-to-clean surfaces can enhance operational efficiencies. A survey by Food & Drug Administration indicated that nearly 30% of food packaging failures are due to improper sealing, emphasizing the importance of investing in user-friendly technology that minimizes error.

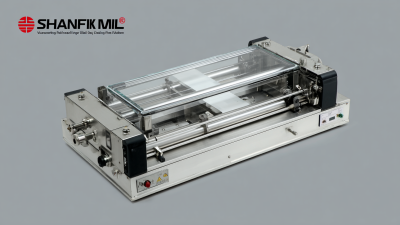

When it comes to procurement strategies for vacuum sealing machines, understanding the specific needs of your operations is essential. Different types of vacuum sealing machines are designed to cater to various requirements, whether it’s for commercial food packaging, kitchen use, or industrial applications. According to a 2022 market analysis by Grand View Research, the global vacuum packaging market is expected to reach $38.83 billion by 2025, emphasizing the growing importance of selecting the right equipment for effective packaging solutions.

For instance, chamber vacuum sealers are ideal for high-volume operations in restaurants or food processing facilities, as they allow for sealing multiple bags at once and ensure a complete vacuum, thus preserving food freshness longer. On the other hand, external vacuum sealers are more suited for home use, where ease of operation and smaller batch sizes are the norms. An industry report from Technavio highlights that the external vacuum sealer segment is projected to grow at a compound annual growth rate (CAGR) of 6% through 2025, reflecting a shift in consumer preferences towards user-friendly machines suited for home kitchens. Understanding these distinctions enables businesses to make informed decisions that align with their specific operational needs.

Establishing a budget for procuring vacuum sealing equipment is a crucial step in ensuring that you maximize your investment while meeting your operational needs. Start by conducting a thorough analysis of your current and projected usage. This will help you understand the capacity and specifications required from the machines. Aim to create a budget that not only accommodates the initial purchase but also considers long-term factors such as maintenance costs and potential upgrades.

When setting your budget, remember to research different brands and models. Prioritize equipment that offers the best value for your specific needs rather than just opting for the cheapest option. Additionally, consider the total cost of ownership, which includes energy consumption and any necessary accessories, as these can significantly impact your overall expenditure. Lastly, it’s beneficial to explore bulk purchasing options or leasing programs, which can provide more flexibility and reduce upfront costs, making your procurement strategy more effective.

When optimizing your vacuum sealing acquisitions, developing strong supplier relationships is crucial. According to a report by MarketsandMarkets, the global vacuum packaging market is projected to grow from $24.1 billion in 2021 to $36.5 billion by 2026, highlighting the increasing demand for efficient sealing solutions. By cultivating partnerships with suppliers, companies can benefit from better pricing strategies, access to the latest technology, and improved customer service. Collaborative relationships often lead to more favorable terms and the chance for joint innovation, especially important as businesses look to enhance operational efficiency.

Furthermore, research conducted by Grand View Research indicates that maintaining long-term supplier relationships can decrease procurement costs by up to 20%. Engaging in open communication with suppliers fosters transparency, allowing for quicker responses to market changes and customer needs. By understanding suppliers' capabilities and constraints, businesses can align their procurement strategies more effectively, ensuring they are not only acquiring high-quality vacuum sealing machines but also tailoring their approach to enhance supply chain resilience. This alignment becomes increasingly vital in a competitive market landscape where agility and responsiveness can dictate success.