Leave Your Message

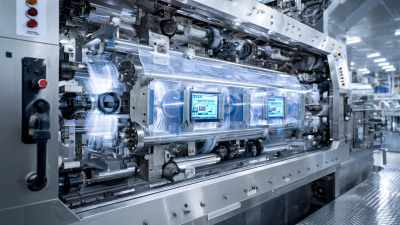

In today’s fast-paced business environment, the integration of advanced Label Printing Machines is crucial for enhancing operational efficiency and meeting the demands of a competitive marketplace. According to a recent industry report by Smithers Pira, the global market for label printing is expected to reach approximately $50 billion by 2024, driven by increasing demand across sectors such as food and beverage, pharmaceuticals, and retail. The adoption of automated labeling systems can reduce errors and improve productivity, with 70% of companies reporting significant time savings and increased accuracy after implementing these technologies. As organizations seek to streamline their processes and reduce operational costs, efficient integration of Label Printing Machines has become an essential strategy for achieving these objectives while delivering high-quality labels that meet regulatory and consumer requirements.

In today's fast-paced business environment, efficient label printing is more than just a convenience; it's a crucial element that can significantly impact operations. Modern businesses rely on accurate and timely labeling for a variety of applications, from product identification to inventory management. Utilizing advanced label printing technologies not only streamlines processes but also enhances productivity, allowing companies to respond quickly to market demands.

Moreover, the integration of label printing machines into business operations can lead to substantial cost savings. By automating the labeling process, businesses can reduce labor costs and minimize human error, ensuring that each product is accurately tagged and ready for distribution. This efficiency not only improves workflow but also boosts customer satisfaction by guaranteeing that products are correctly labeled, which is essential for compliance and traceability in many industries. As businesses continue to leverage technology for growth, the importance of efficient label printing remains paramount in maintaining a competitive edge.

When integrating a label printing machine into your business, several key components play a crucial role in ensuring efficiency and productivity. First and foremost, a seamless software interface is essential. It should be able to communicate effectively with your existing inventory and order management systems. This integration streamlines the design, printing, and application of labels, thereby reducing the risk of errors and enhancing workflow. Choose a solution that allows for easy data import and batch printing, which significantly speeds up the process.

Another critical component is the hardware compatibility. The label printing machine should be compatible with various types of labels and materials to cater to your specific needs. Additionally, consider the speed and resolution of the printer, as these factors directly impact your output quality. Investing in a high-quality printer with advanced features, such as automatic cutting and label alignment, can further enhance operational efficiency. By focusing on these elements, businesses can ensure that their label printing machine integration not only meets current demands but also scales with future growth.

In today’s fast-paced business environment, the integration of efficient label printing solutions can significantly enhance operational productivity. According to a report by Smithers Pira, the global label market is projected to reach $50 billion by 2025, driven by the increasing demand for product labeling across various industry sectors. For instance, companies like Coca-Cola have successfully leveraged advanced label printing technologies to optimize their manufacturing processes and reduce waste. They implemented on-demand digital printing which not only minimized inventory costs but also allowed for rapid response to market trends by quickly changing designs and information on products.

Another example is the pharmaceutical industry, where regulatory compliance and traceability are crucial. According to a study by the National Association of Manufacturers, integrating automated label printing systems can reduce labeling mistakes by up to 45%, ensuring that products are accurately tracked throughout the supply chain. Companies like Johnson & Johnson have adopted such solutions, which streamline their packaging processes and improve accuracy, ensuring that every product meets stringent safety standards. This integration of innovative label printing technologies is not merely a trend; it is a strategic move towards efficiency and competitiveness in the market.

Integrating label printing machines into your business operations can significantly enhance efficiency, but several common challenges may arise. One major issue is compatibility with existing systems. Businesses often struggle when new machines do not work seamlessly with their current software or hardware. To mitigate this, always ensure that the label printing machines you consider use standardized protocols or provide robust API integrations. This can streamline communication between devices and software, preventing potential headaches during implementation.

Another challenge often faced is the training of staff on new equipment. Employees may be hesitant to adopt new technology, leading to disruptions in productivity. A solution to this issue is to invest in comprehensive training programs that include hands-on workshops and easily accessible resources. Encouraging an open dialogue during training can also alleviate concerns and build confidence in using the new machinery.

Lastly, maintenance and troubleshooting can be daunting for businesses. Unexpected downtime can be costly, so it’s essential to have a well-defined maintenance schedule and support plan in place. Regular check-ups and a clear process for reporting issues can help keep operations running smoothly. Implementing these strategies can pave the way for a smoother integration process and boost overall productivity.

| Challenge | Description | Solution | Expected Outcome |

|---|---|---|---|

| Incompatibility with Existing Systems | New machines may not interface smoothly with legacy systems leading to downtime. | Conduct a system compatibility audit before purchase and choose machines that support integrations. | Reduced downtime and improved system efficiency. |

| Training and Skill Gaps | Staff may be unfamiliar with new printing technology and software. | Implement comprehensive training programs and create user manuals and resources. | Increased employee proficiency and output quality. |

| Maintenance and Support | Challenges in troubleshooting and maintaining equipment can arise. | Establish a maintenance schedule and partner with reliable service providers for support. | Minimized downtime and prolonged equipment lifespan. |

| Supply Chain Issues | Delays in obtaining label materials can impact production schedules. | Identify multiple suppliers and maintain inventory buffers for critical materials. | More consistent production timelines and reduced risk of stockouts. |

| Quality Control | Ensuring labels meet quality standards can be challenging with rapid production. | Implement automated quality checks and regular testing protocols. | Higher quality output with fewer defects, improving customer satisfaction. |

As businesses increasingly pivot towards digital transformation, the label printing sector is witnessing remarkable advancements. According to a recent report from Smithers Pira, the global label printing market is estimated to reach $49 billion by 2024, driven by the rise in e-commerce and the demand for customized packaging solutions. Companies are now integrating advanced technologies such as digital printing, automation, and AI to streamline their operations and enhance output quality.

To effectively integrate these innovations, businesses should focus on a few strategic areas. First, adopting a modular printing system can facilitate scalability and flexibility. This approach allows businesses to upgrade or replace specific components as technology evolves, rather than overhauling the entire system. Additionally, training staff on new technologies is essential to maximizing efficiency and reducing downtime, as highlighted in a report by Research and Markets, which noted that proper training can improve productivity by up to 30%.

Tip: Always assess the compatibility of new label printing technologies with your existing systems to minimize integration challenges. Moreover, consider leveraging cloud-based solutions for real-time tracking and data analysis, enabling more informed decision-making and smoother operations as your business grows. Embracing these future trends not only positions your business to thrive today but also ensures longevity in a rapidly changing marketplace.