Leave Your Message

In the rapidly evolving landscape of packaging solutions, the Vacuum Packing Machine stands out as a pivotal innovation, driving efficiency and sustainability in various industries. According to a recent report by Markets and Markets, the vacuum packaging market is projected to reach $32.63 billion by 2025, growing at a CAGR of 5.3%. This rise is primarily attributed to the increasing demand for packaged food products and the expansion of e-commerce, necessitating effective preservation methods. Additionally, the advancement in technology has resulted in vacuum packing machines that not only enhance product longevity but also minimize spoilage and waste, contributing to environmental sustainability. Furthermore, understanding the advantages of after-sales service and maintenance costs associated with these machines can significantly influence procurement decisions, making it imperative for businesses to consider these factors as they invest in future-ready packaging solutions.

In today's fast-paced world, businesses seek innovative ways to improve efficiency in their packaging processes. Traditional packaging methods are increasingly being challenged by advanced techniques like vacuum packing. This method not only preserves products for a longer duration but also minimizes waste, making it an eco-friendly alternative. Embracing vacuum packing technology can enhance storage optimization and reduce transport costs, ultimately benefiting both companies and consumers.

As companies explore various alternatives to conventional packaging, here are some tips to consider. First, assess the nature of your products—perishable or non-perishable—to determine whether vacuum packing is appropriate. Second, invest in a reliable vacuum packing machine that meets your production needs while offering customizable options for different product sizes. Lastly, incorporate sustainable materials into your packaging strategy; using recyclable or biodegradable materials can significantly enhance your brand's image and appeal to environmentally conscious consumers.

Exploring these alternatives not only increases operational efficiency but also positions businesses as leaders in sustainability. Embracing modern technologies and materials ensures a competitive edge in a marketplace that increasingly values both quality and responsibility.

| Packaging Method | Efficiency Rating | Cost (per unit) | Environmental Impact | Shelf Life Extension |

|---|---|---|---|---|

| Vacuum Packing | High | $0.30 | Low | Up to 5 times |

| Modified Atmosphere Packaging (MAP) | Medium | $0.40 | Moderate | 3 to 4 times |

| Shrink Wrapping | Medium | $0.25 | Moderate | 2 to 3 times |

| Foil Packaging | High | $0.50 | Low | 3 to 5 times |

| Biodegradable Packaging | Medium | $0.45 | Very Low | 2 to 3 times |

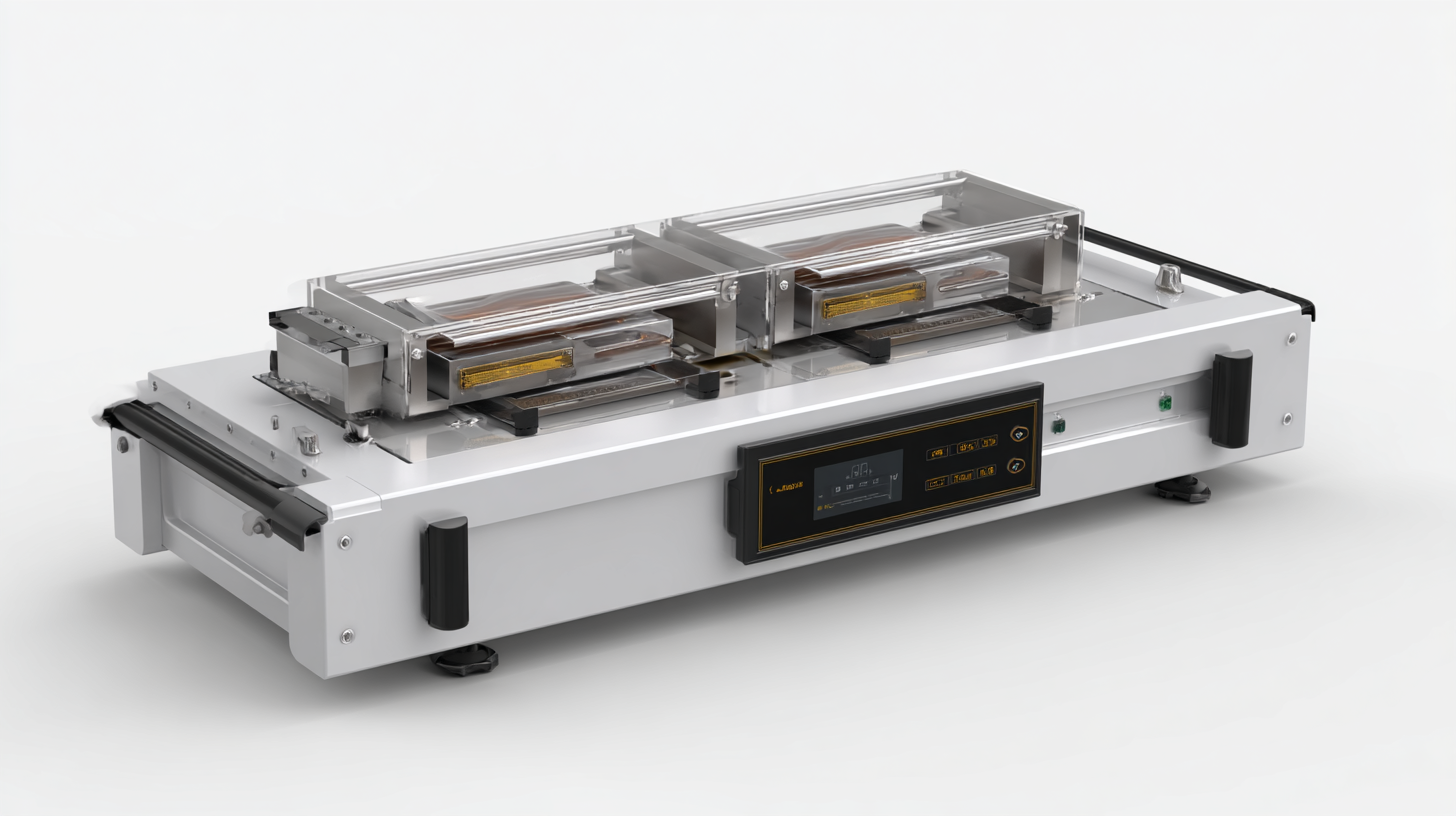

In the quest for sustainable packaging solutions, vacuum packing machines have emerged as a vital tool for businesses aiming to reduce waste and enhance efficiency. By removing air from packaging, these machines not only prolong the shelf life of products but also minimize the volume of materials used. This process leads to significant reductions in plastic waste, as less packaging material is needed to effectively preserve food and other perishables. Moreover, vacuum packing optimizes storage and transportation, allowing companies to move more products with less environmental impact.

The versatility of vacuum packing machines extends beyond food preservation to a range of industries, including e-commerce and pharmaceuticals. In e-commerce, for instance, using vacuum-sealed bags can reduce shipping costs and lessen the carbon footprint associated with transporting products. Additionally, in the pharmaceutical sector, vacuum packing ensures the integrity and safety of sensitive materials, which is crucial for maintaining efficacy. Overall, the integration of vacuum packing technology into various industries is not only a smart business decision but also a crucial step toward a more sustainable future.

In the realm of packaging solutions, vacuum packing stands out as a superior choice compared to traditional methods like box packing and shrink wrapping. Vacuum packing works by removing air from the packaging before sealing, which significantly extends the shelf life of products by minimizing oxidation and inhibiting bacterial growth. This method is particularly advantageous for perishable goods such as food, where freshness is paramount. Compared to other techniques, vacuum packing offers notable efficiency and effectiveness, keeping products fresher for longer and reducing waste.

Moreover, the compact nature of vacuum-packed items contributes to efficient storage and transportation. Unlike rigid packaging, which occupies more space, vacuum packing allows for a more flexible arrangement in storage areas and transport vehicles. This not only optimizes space but also reduces shipping costs, making it a more economical choice for businesses. As sustainability becomes increasingly important, the minimalist approach of vacuum packing aligns well with eco-friendly practices, utilizing less material and reducing the carbon footprint associated with packaging waste. In contrast, other packaging techniques often involve more complex materials that can have a greater environmental impact.

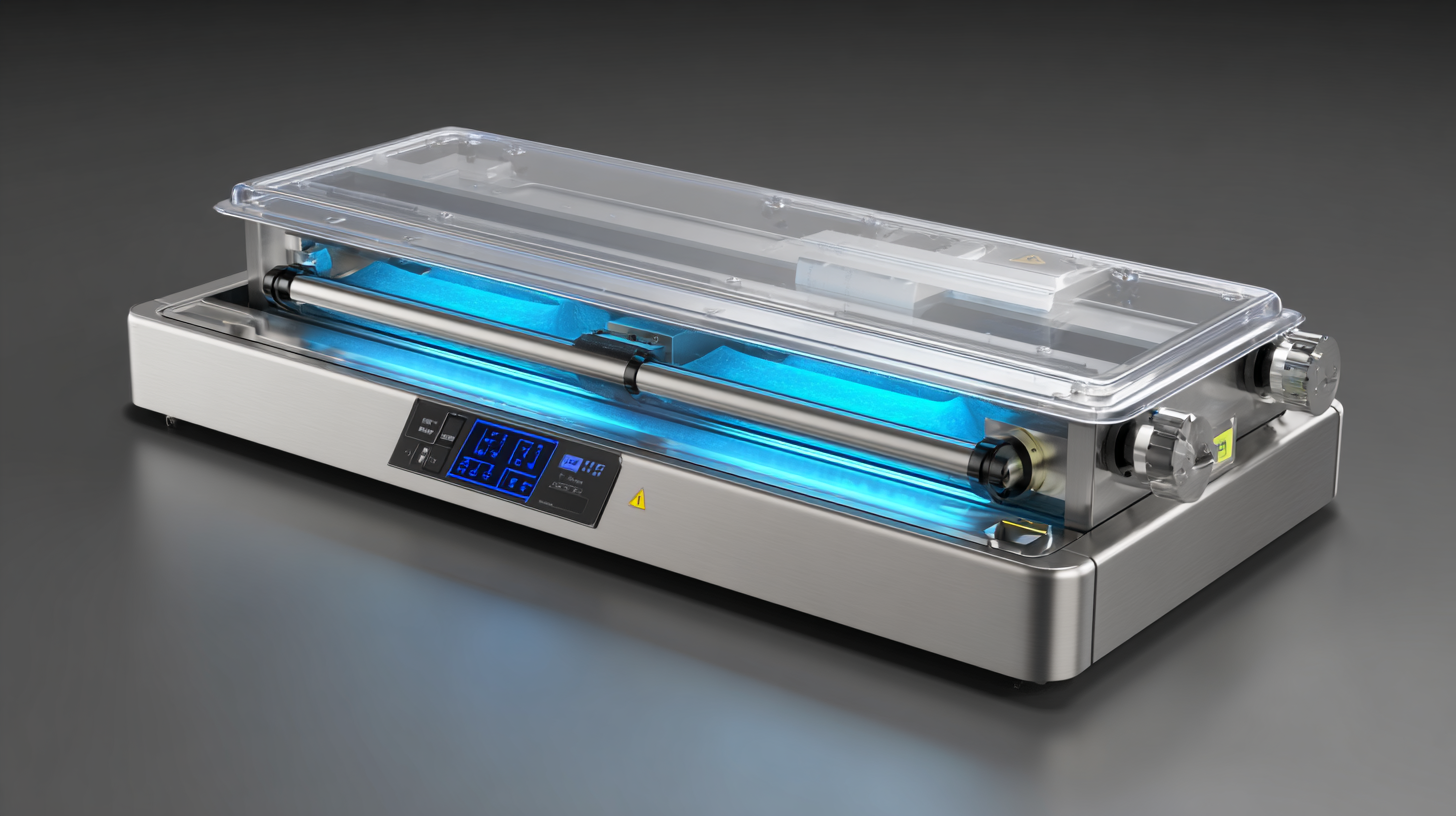

Vacuum packing technology has undergone significant advancements in recent years, revolutionizing the way products are packaged across various industries. The latest innovations focus on improving efficiency, reducing waste, and enhancing product longevity. One notable development is the integration of smart sensors in vacuum packing machines, which optimize the sealing process by adjusting variables such as temperature and pressure in real time. This not only minimizes the risk of spoilage due to improper sealing but also ensures that the maximum shelf life is achieved for perishable items.

Moreover, the introduction of eco-friendly materials in vacuum packaging is transforming the landscape of sustainable packing solutions. Traditional plastic films are being replaced with biodegradable options that maintain product freshness without harming the environment. Coupled with advanced vacuum packing technology, these materials provide a dual benefit of efficiency and sustainability, appealing to environmentally conscious consumers. As businesses strive to enhance their operational practices, investing in innovative vacuum packing solutions will be pivotal for maximizing productivity and minimizing their ecological footprint.

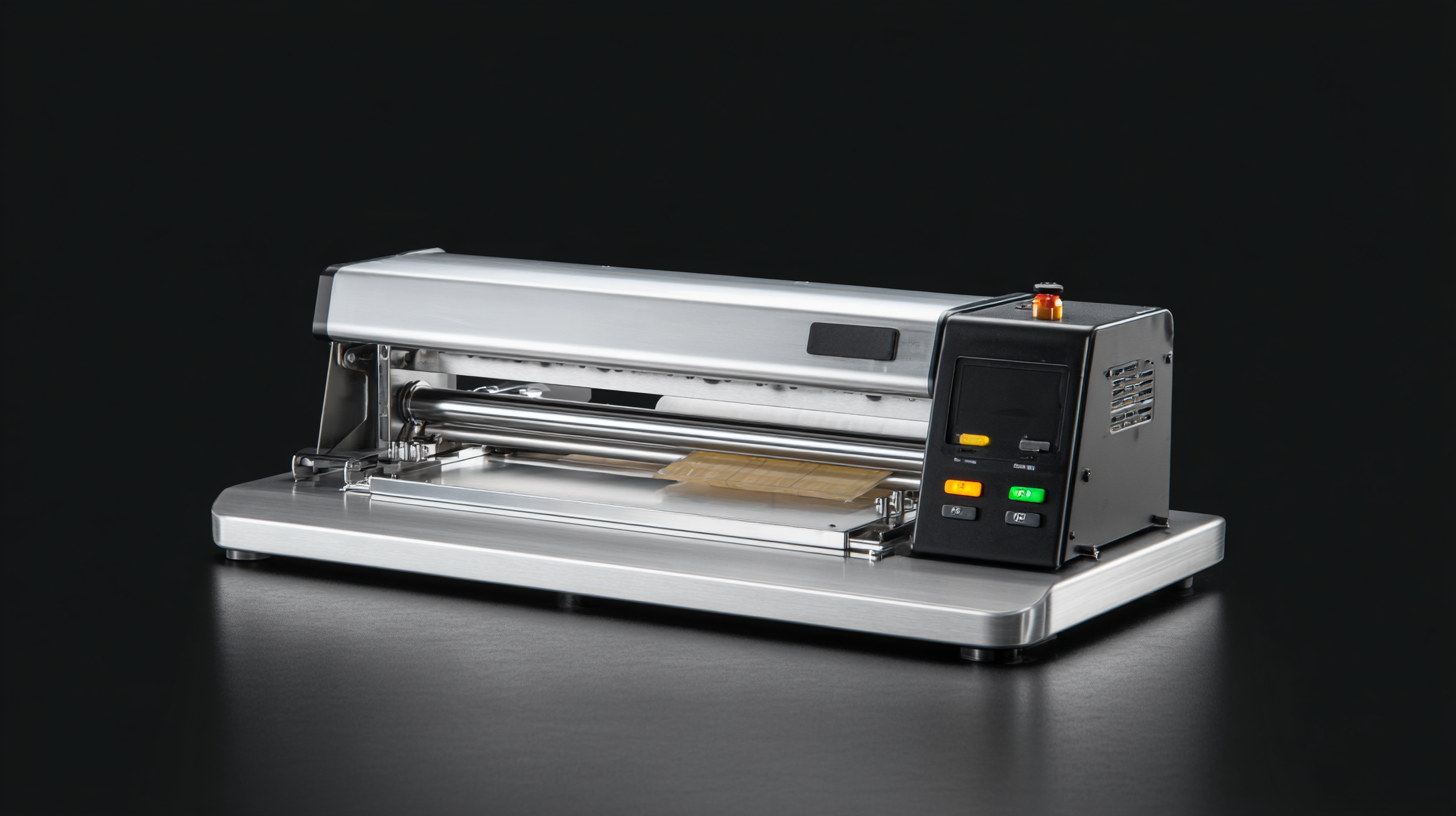

Choosing the right vacuum packing machine is essential for businesses looking to optimize their packaging processes. With the global demand for fresh produce expected to soar, projected to reach over over $63 billion by 2033, the efficiency of packaging solutions has become a focal point in the food industry. A vacuum packing machine not only helps in retaining the freshness of fruits and vegetables but also plays a significant role in extending shelf life, reducing waste, and ultimately lowering operational costs.

When selecting a vacuum packing machine, it's crucial to consider various factors that align with your specific packaging needs. The market for vacuum packing machines is anticipated to surpass $4.9 billion by 2024, driven by the increasing demand for optimized food preservation. Features such as ease of use, speed, and energy efficiency are vital for small businesses and large-scale operations alike. As companies strive to minimize moisture loss while presenting their products attractively, investing in the right vacuum packing technology is becoming an indispensable part of their packaging strategy.