Leave Your Message

In the rapidly evolving landscape of global packaging solutions, the role of the Shrink Packing Machine has become increasingly vital. According to a recent report by MarketsandMarkets, the shrink packaging market is projected to grow from USD 24.7 billion in 2020 to USD 36.7 billion by 2025, reflecting a compound annual growth rate (CAGR) of 8.5%. This surge is driven by the increasing demand for packaging that offers product protection, extended shelf life, and enhanced visibility on retail shelves.

As businesses seek to optimize their packaging processes and meet consumer demands for sustainability and efficiency, choosing a high-quality manufacturer of shrink packing machines is paramount. In this blog, we will explore the key factors to consider when selecting a manufacturer, ensuring that businesses can harness the full potential of shrink packaging technology for their operational needs.

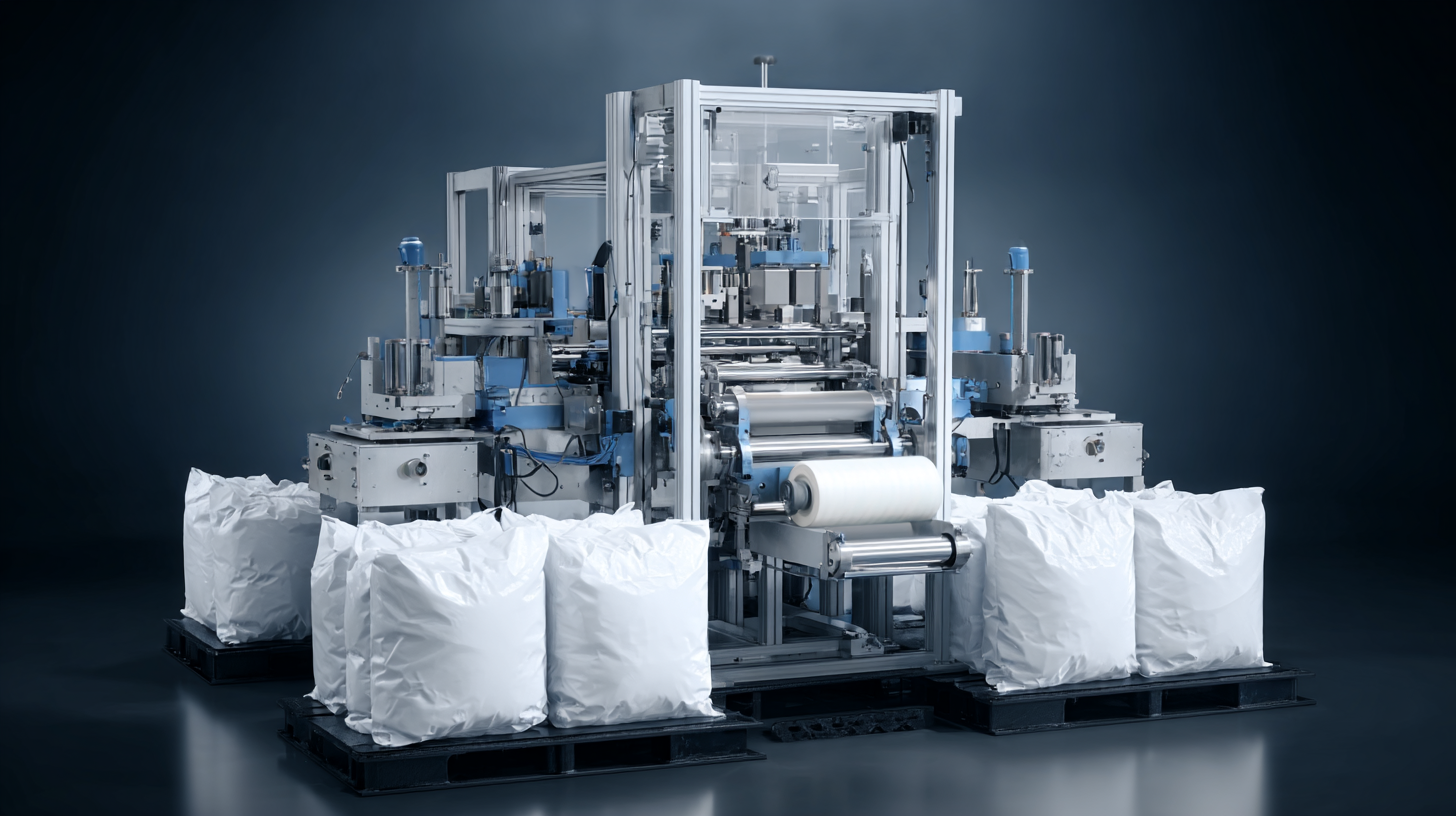

In the fast-paced world of e-commerce, shrink packing machines have emerged as essential tools for businesses aiming to elevate their packaging solutions. As online shopping continues to thrive, the demand for efficient, durable, and visually appealing packaging has never been greater. Shrink packing machines offer a versatile solution by securely bundling products, reducing the risk of damage during transit, and providing a polished, professional presentation that enhances brand image.

The advantages of shrink packing extend beyond aesthetics and protection. These machines improve operational efficiency by speeding up the packaging process and minimizing manual labor. This automation allows companies to focus on scaling their operations while maintaining quality control. As sustainability becomes increasingly important, shrink packing materials can also be sourced from eco-friendly options, aligning business practices with environmentally conscious consumers. As e-commerce continues to grow, the integration of advanced shrink packing technology is likely to play a pivotal role in shaping the future of packaging solutions across the globe.

| Dimension | Data |

|---|---|

| Global Shrink Packaging Market Size (2023) | $9.5 billion |

| Expected CAGR (2023-2028) | 4.7% |

| E-Commerce Share of Packaging (2023) | 35% |

| Key Drivers for Shrink Packaging | Product Protection, Aesthetic Appeal, Cost-Effectiveness |

| Popular Materials Used | PVC, PE, PP |

| Common Applications | Food & Beverage, Electronics, Cosmetics |

| Sustainability Trends | Recyclable Materials, Reduced Plastic Use |

The shrink packing technology landscape is undergoing a significant transformation, driven by advances in machinery, materials, and automation. As businesses strive to meet escalating consumer demands, the global market for shrink packing machines is expected to witness substantial growth by 2025. Key factors influencing this trend include the rise of e-commerce, which requires efficient and secure packaging solutions to ensure product integrity during shipping. Innovations in shrink film materials that offer enhanced durability and sustainability are also shaping market dynamics, with companies increasingly focusing on environmental responsibility.

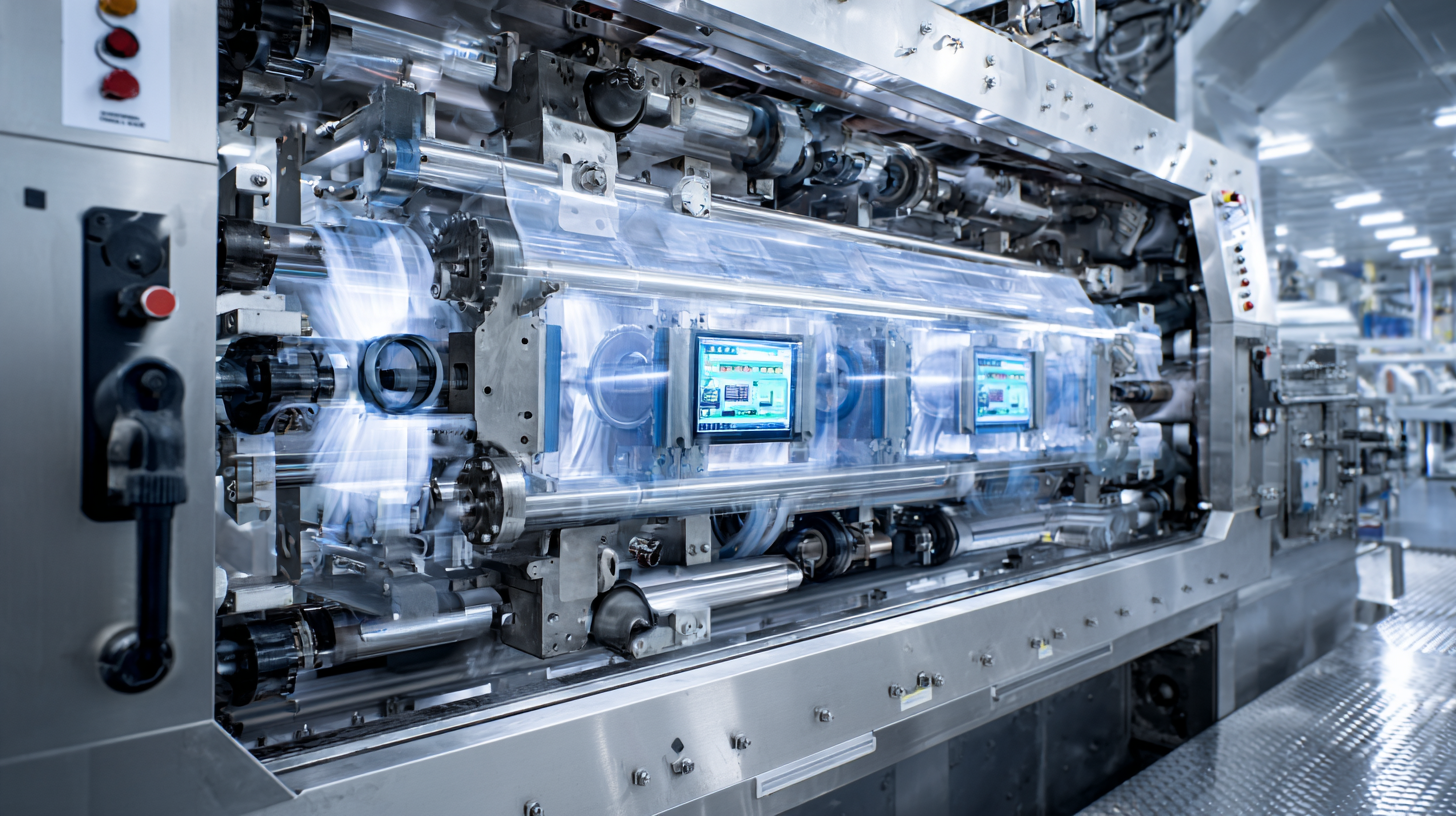

Moreover, the integration of smart technologies within shrink packing machines is revolutionizing production lines. Automated systems equipped with IoT capabilities allow for real-time monitoring and optimization, improving operational efficiencies and reducing waste. This shift is particularly favorable for industries requiring high-speed packaging solutions, such as food and beverage, cosmetics, and pharmaceuticals. As manufacturers adapt to these evolving trends, the emphasis will likely be on enhancing user experience while maximizing throughput, setting the stage for the next generation of shrink packing technology.

This bar chart illustrates the projected market growth of shrink packing machines from 2021 to 2025, indicating a significant upward trend in the industry as global packaging solutions continue to evolve.

The shrink packing industry is undergoing a significant transformation, driven by key players committed to innovation. Companies such as Sealed Air Corporation, Aetna Group, and Clysar LLC are at the forefront, developing advanced machines that enhance efficiency and sustainability. According to a recent market analysis, the global shrink packaging market is projected to reach $25 billion by 2027, growing at a CAGR of 4.5% from 2022 to 2027. This growth is propelled by increasing demand for packaged goods across various sectors, including food, pharmaceuticals, and consumer products.

As competition intensifies, companies are integrating smart technology into their shrink packing solutions. Implementing state-of-the-art features, such as automated controls and AI-driven systems, enables manufacturers to optimize production workflows and reduce material waste. Furthermore, the shift towards environmentally friendly packaging materials is pushing industry players to innovate. According to the Sustainable Packaging Coalition, approximately 67% of consumers prioritize sustainability when making purchasing decisions, prompting companies to adapt their practices to meet consumer expectations.

Tip: When choosing a shrink packing machine, consider the integration of eco-friendly materials and automation features to enhance both sustainability and efficiency in your packaging operations. Additionally, keeping abreast of regulatory requirements and consumer trends can help companies remain competitive in this rapidly evolving market.

As the global packaging industry shifts towards sustainability, shrink packing machine manufacturers are adapting their development strategies to meet the rising demand for eco-friendly solutions. The pressure to minimize environmental impact has led to innovations in materials and processes. Companies are now exploring biodegradable films and recyclable materials to replace traditional plastics, ensuring that their shrink packing solutions align with sustainability goals.

Furthermore, advancements in energy-efficient technologies are becoming a priority within the development of shrink packing machines. Manufacturers are investing in machines that consume less power, reduce waste, and enhance overall efficiency. This shift not only improves the carbon footprint of packaging operations but also translates to cost savings for companies. By embracing such technologies, the industry is setting a new standard for responsible manufacturing practices that prioritize both performance and environmental stewardship.

The future of shrink packing machines, therefore, lies in a harmonious blend of innovation and sustainability, pushing businesses to recalibrate their approaches toward packaging solutions. As consumer awareness grows and regulations tighten, the evolution of these machines will be pivotal in shaping a sustainable packaging landscape.

The shrink packing machine industry is poised for remarkable growth as global demand for efficient packaging solutions continues to rise. According to recent projections, the market for shrink packing solutions is expected to reach new heights by 2025, showcasing a significant surge in revenue driven by increased consumer expectations for convenience, sustainability, and product protection. This shift is being fueled by various sectors including food and beverage, pharmaceuticals, and electronics, which are all seeking innovative ways to enhance their packaging processes.

One of the key factors contributing to this growth is the technological advancements in shrink wrapping equipment. As manufacturers invest in more sophisticated machines that offer higher speeds, improved reliability, and versatility to handle diverse products, the efficiency of packaging operations will enhance significantly. Furthermore, the shift toward eco-friendly materials and processes is encouraging companies to adopt shrink packing solutions that not only meet market demands but also align with sustainability goals.

With an increasing emphasis on reducing waste and optimizing resources, the shrink packing market is set to capture a larger share of the global packaging landscape in the coming years.