Leave Your Message

In the rapidly evolving food processing industry, the significance of a reliable Can Sealer Machine cannot be overstated. According to a recent report by Industry Research, the global canning market is projected to reach USD 33.43 billion by 2026, growing at a CAGR of 4.5% from 2021. This surge in demand emphasizes the crucial role that effective sealing technology plays in preserving product quality and extending shelf life. Choosing the right can sealer machine is essential for businesses looking to enhance operational efficiency and ensure compliance with strict safety standards. The proper equipment not only reduces waste and increases productivity but also meets consumer expectations for freshness and reliability. In this ultimate guide, we will explore the key considerations and tips that will help you select the perfect can sealer machine tailored to your business needs.

When selecting the right can sealer machine for your business, several key considerations must be taken into account to ensure that it meets your operational needs. Firstly, assess the type of products you plan to seal. Different can sealer machines are designed for specific materials and closure types, such as metal, plastic, or glass cans. Understanding the size and shape of your containers is also crucial; this will help you choose a machine that accommodates your product line without compromising efficiency.

Another important factor is the production volume you anticipate. If your operation is high-volume, look for machines that offer faster sealing cycles and automation capabilities. On the other hand, for smaller operations, a manual or semi-automated can sealer may be more cost-effective. Additionally, consider the complexity of operation. Intuitive controls can streamline training for staff and minimize downtime, whereas more complicated machinery might necessitate specialized training, increasing your initial investment and operating costs.

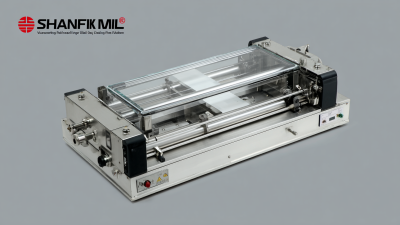

When choosing the right can sealer machine for your business, it’s crucial to understand the various types available on the market. Can sealers primarily fall under two categories: semi-automatic and fully automatic machines. Semi-automatic machines require manual input for loading cans and sealing, making them a cost-effective solution for small to mid-sized production facilities. In contrast, fully automatic can sealers streamline the entire process, significantly enhancing productivity by automatically handling the filling, sealing, and even labeling of cans. According to a recent industry report by Grand View Research, the global can sealing machine market is expected to grow at a compound annual growth rate (CAGR) of 4.5% from 2021 to 2028, indicating a rising demand for these machines as businesses scale up operations.

Another critical consideration in selecting a can sealer machine is the type of sealing method utilized. The two most common methods are double seaming and induction sealing. Double seaming is often preferred for metal cans, providing a robust seal that enhances product shelf life and prevents contamination. On the other hand, induction sealing is typically used for plastic or glass containers and involves applying high-frequency electromagnetic fields to create an airtight seal. According to a report by MarketsandMarkets, the global induction sealing market is projected to grow from USD 4.23 billion in 2021 to USD 6.34 billion by 2026, illustrating a significant shift towards modern sealing technologies catering to diverse packaging needs. Understanding these types and methods will aid businesses in making informed decisions that align with their production requirements.

This chart illustrates the average pricing and production capacity of various types of can sealer machines available in the market, which can help businesses make informed decisions when choosing the right equipment.

When selecting a can sealer machine for your business needs, there are essential features that should be at the forefront of your decision-making process. First and foremost, consider the type of cans you will be sealing. Different machines are designed for various can sizes and materials; ensure that the model you choose is compatible with your specific requirements. Additionally, look for machines that offer adjustable sealing pressure and speed settings, as these features will allow you to tailor the sealing process to your product's unique needs.

Tip: Always check for user-friendly controls and intuitive interfaces. Machines that are easy to operate can help minimize training time for your staff, leading to increased productivity and efficiency.

Another crucial aspect to consider is the machine's durability and maintenance requirements. A robust machine will withstand daily operations without frequent breakdowns, while low maintenance designs can save you time and money in the long run. Also, consider the level of automation you require. Fully automated machines can significantly speed up production but may require a higher upfront investment.

Tip: Read customer reviews and consult with industry experts to find out which machines stand the test of time and provide reliable performance. This insight can help you make an informed choice that aligns with your business goals.

When evaluating the efficiency and performance of a can sealer machine, it is essential to assess several key factors that significantly impact your production capabilities. First and foremost, consider the machine's sealing speed. A higher sealing rate will not only enhance productivity but also help meet demand during peak operational hours. Look for specifications that indicate the number of cans sealed per minute and ensure that it aligns with your production goals.

Another critical aspect to evaluate is the consistency of the seal quality. An efficient can sealer should provide reliable hermetic seals that prevent leaks and maintain product integrity. Review user experiences and product reviews to identify machines that have a proven track record of consistent performance. Additionally, features like adjustable sealing pressure and temperature control can contribute to better performance by accommodating different can materials and sizes, ensuring versatility for your business's diverse needs. By focusing on these factors, you can make an informed decision that enhances your production line's efficiency and overall output.

| Feature | Detail | Considerations |

|---|---|---|

| Sealing Speed | 30 cans per minute | Choose depending on production volume |

| Machine Type | Semi-Automatic | Requires manual operation for can loading |

| Power Consumption | 1.5 kW | Consider energy costs |

| Compatibility | Works with 250ml to 500ml cans | Ensure size matches your products |

| Maintenance Requirements | Regular lubrication needed | Factor maintenance into operational costs |

| Price Range | $3,000 - $5,000 | Set a budget before shopping |

| Warranty | 2 years standard | Review terms before purchase |

When budgeting for a can sealer machine, several cost factors come into play that can significantly affect your overall investment. According to a recent industry report by IBISWorld, the canning machinery market has grown steadily, with revenue expected to reach $2.5 billion by 2024. This growth indicates that selecting the right can sealer is not just a mundane purchase but a crucial business decision affecting production efficiency and product quality.

One key aspect to consider is the type of machine that fits your production scale. For small-scale operations, semi-automatic can sealers may suffice, costing around $1,200 to $5,000. However, larger businesses might require fully automatic models, which can range from $20,000 to $100,000. Tips for budgeting include evaluating your production needs and understanding maintenance costs, which can add up to 15% of the initial investment annually.

Another critical factor is the material and technology used in the can sealer. High-quality stainless steel machines with advanced features typically have a higher upfront cost but offer better durability and performance, ultimately resulting in long-term savings. Ensure you factor in these costs and look for models that provide a warranty or service plan, as these can reduce unexpected expenses.