Leave Your Message

A Heat Sealing Machine is an essential tool in packaging industries. It uses heat to bond materials together, ensuring products remain secure. This process is vital for preserving freshness and preventing contamination. The machine operates by applying heat and pressure, melting the material at the edges. This creates a strong seal that holds two surfaces together.

While the technology seems straightforward, there are nuances to consider. For instance, choosing the right temperature and time settings is crucial. Too much heat can damage materials. Too little may lead to weak seals. It's a delicate balance. Additionally, different materials may require tailored approaches, which adds complexity to the process.

Understanding a Heat Sealing Machine also means recognizing its limitations. It may not work well on all types of materials. Sometimes, users face challenges with speed and efficiency. Learning from these challenges can lead to improvements. Each attempt offers insights into better usage and maintenance. This continuous learning journey enhances not only the product quality but also user proficiency.

A heat sealing machine is an essential tool in various industries, primarily for packaging. Its main purpose is to bond materials using heat and pressure. These machines come in different forms, including hand-operated and automated models. They are often used in the food, medical, and textile sectors. A well-functioning heat sealing machine ensures that products remain contained and safe from external elements.

Tip: Regular maintenance is vital. Check the heating elements frequently. If they wear out, you risk incomplete seals and product spoilage. Make it a routine to inspect seals before significant production runs.

Heat sealing machines work by applying heat to specific areas, melting the materials to create a strong bond. For best results, it’s important to choose the right temperature and pressure settings. Too much heat can cause damage, while too little may lead to weak seals. Finding the perfect balance might take time and experimentation.

Tip: Consider keeping a log of various settings used. Documenting results can help you refine your process. This can save time and reduce wastage in the long run.

Heat sealing machines play a vital role in packaging. Their core components include heating elements, pressure controls, and sealing bars. The heating element generates the necessary temperature to melt the materials. It’s often made from durable materials that resist wear. Pressure controls ensure that the right amount of force is applied during sealing. These settings can vary, affecting the quality and strength of the seal.

The sealing bar is crucial for a tight closure. It often utilizes different technologies, such as impulse or continuous sealing. Each has its pros and cons, and choosing the right one can be tricky. Impulse sealing is energy-efficient but may struggle with thicker materials. Continuous sealing, on the other hand, offers speed but can sometimes create uneven seals.

Understanding these components helps in optimizing the machine’s performance. Issues often arise from improper temperature settings or incorrect pressure application. Regular maintenance is essential but often overlooked. It’s a reminder that effective sealing goes beyond just machinery; it requires attention to detail and testing. Balancing these factors can lead to improved packaging quality, ultimately enhancing product integrity.

Heat sealing machines play a critical role in various industries, including food packaging and textiles. The process of heat sealing involves applying heat and pressure to join materials together. This method creates durable seals that can withstand various environmental conditions. According to industry reports, the global heat sealing equipment market is expected to reach USD 2.7 billion by 2026, reflecting the growing demand for efficient sealing processes.

The heat sealing process begins with selecting appropriate materials. Commonly used are plastics and films that have thermoplastic properties. Operators place the materials between two sealing jaws. These jaws heat up rapidly, applying pressure to the materials. This combination of heat and pressure causes the materials to melt slightly, fusing them into a secure bond. Insight reports suggest that improper temperature settings can lead to weak seals, highlighting the importance of precise control.

Once the sealing is complete, the machine cools the seal zone to solidify the bond. This phase is crucial; if cooled improperly, the integrity of the seal may be compromised. As per data from industry analysts, about 20% of sealing failures are attributed to inadequate cooling. This emphasizes the need for careful calibration and monitoring during the heat sealing process. Continuous improvement in techniques and technology can help mitigate these challenges, ensuring better efficiency and product quality.

| Dimension | Description |

|---|---|

| Type | Continuous Heat Sealing |

| Common Uses | Packaging food, medical supplies, and consumer goods |

| Heat Source | Electric heating elements or heated plates |

| Materials | Plastic films, foils, and laminated materials |

| Advantages | High-speed sealing, reliable seals, cost-effective |

| Process Steps | Preparation, heating, sealing, cooling |

| Safety Features | Temperature control, emergency stop, safety guards |

When choosing a heat sealing machine, consider the specific needs of your projects. Different types of heat sealers serve various purposes. For example, impulse sealers are great for small batch sealing. These machines heat up quickly and seal bags with minimal training. However, they may not last long with heavy use.

Another option is continuous heat sealers. These machines are ideal for high-volume production. They provide a constant seal and can handle thicker materials. This type may be more complex to set up, which can be a challenge for beginners. Not everyone may feel equipped to use the features effectively.

Finally, bag sealers utilize a simpler mechanism. They are user-friendly and perfect for home use. However, they might lack the durability needed for larger operations. Understanding your production scale, material types, and desired seal strength is essential. The right choice is often a balance of capability and ease of use, which can be difficult to find.

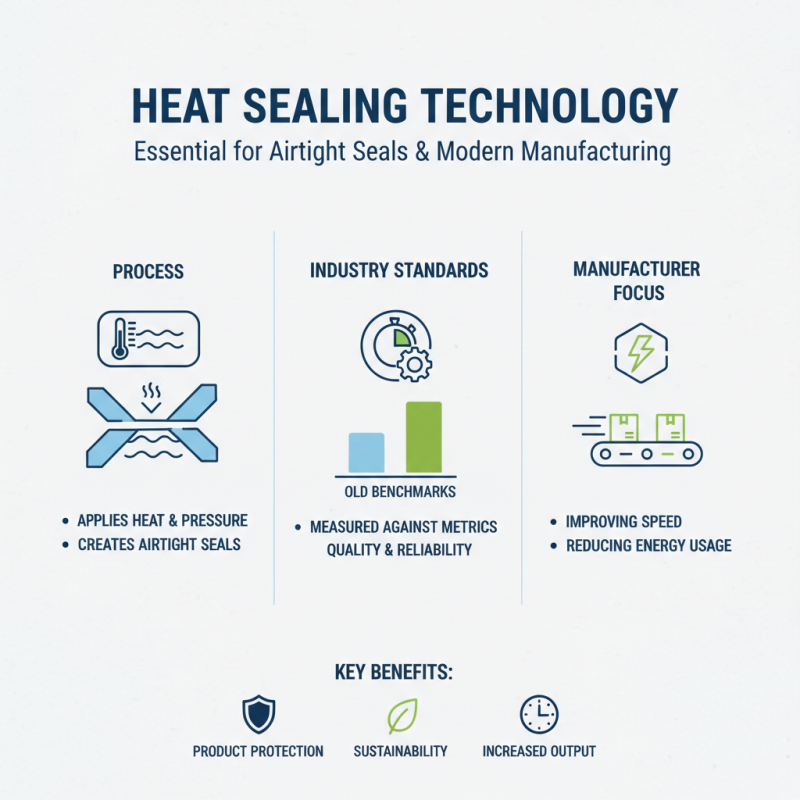

Heat sealing technology plays a crucial role in many industries. This process creates airtight seals by applying heat and pressure. The efficiency of these machines is often measured against industry standards. Manufacturers focus on improving speed and energy usage. This is vital in today's fast-paced market.

Efficiency metrics can include seal strength and cycle time. Seal strength must meet specific requirements to withstand handling and transportation stresses. Cycle time measures how fast a machine can seal materials. Shorter times increase production, but compromise may occur in seal integrity. Finding the right balance is essential for optimizing performance.

Moreover, manufacturers must adhere to safety standards. Workers need proper training to operate machines safely. Issues occasionally arise with overheating and equipment malfunction. Regular maintenance is required to prevent accidents. This highlights the importance of ongoing evaluation to enhance both safety and efficiency in heat sealing technology.