Leave Your Message

The advancements in Vacuum Packaging Machine technology have become increasingly significant in enhancing food preservation, extending shelf life, and reducing waste in the food industry. As highlighted in the latest market report from Research and Markets, the global vacuum packaging market is projected to grow from USD 23.6 billion in 2022 to USD 36.5 billion by 2027, with a compound annual growth rate (CAGR) of 9.3%. This growth is partly driven by the rising demand for convenience food and the need for effective packaging solutions that ensure product integrity during storage and transport. At the upcoming 138th Canton Fair in 2025, innovations in vacuum packaging machines will take center stage, showcasing cutting-edge technologies that cater to these market demands. Manufacturers are increasingly focusing on automation, eco-friendliness, and smart features, further solidifying the importance of vacuum packaging machines in the modern supply chain.

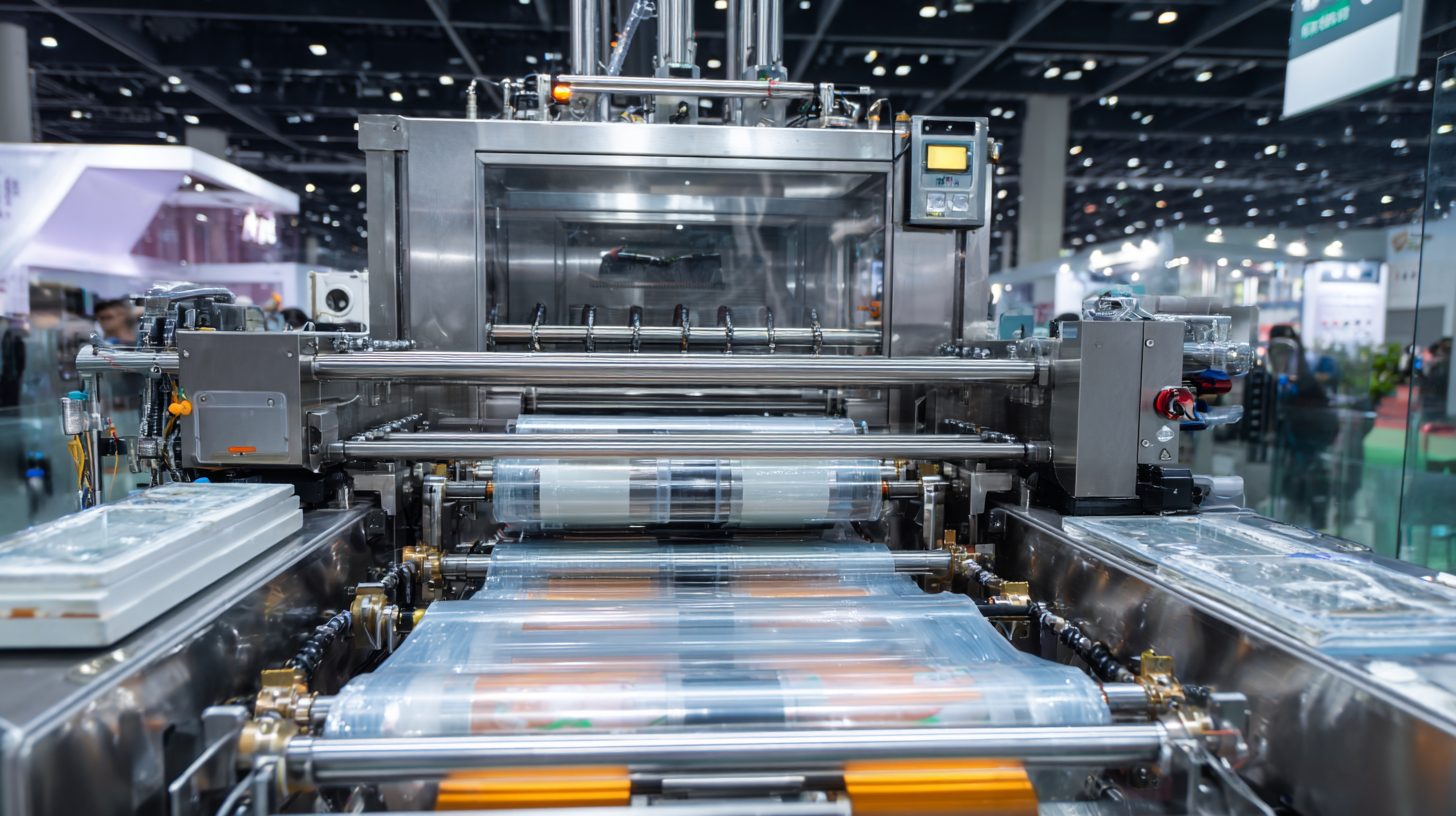

At the 138th Canton Fair in 2025, the spotlight on vacuum packaging machines revealed a myriad of innovative trends reshaping how products are packaged and preserved. This year, manufacturers showcased cutting-edge technologies that emphasize efficiency, sustainability, and versatility. Advanced features such as intelligent control systems and enhanced sealing techniques highlight a shift toward automation, allowing for faster production rates and improved consistency in packaging quality.

Sustainability also took center stage, with many exhibitors presenting eco-friendly materials and energy-efficient machines. Innovations in biodegradable packaging solutions align with the growing demand for environmentally responsible practices in the food and consumer goods sectors. Additionally, the integration of smart technology, such as IoT capabilities in vacuum packaging machines, facilitates real-time monitoring and data analysis, enabling businesses to optimize their operations and reduce waste. The trends observed at the fair not only reflect the current market needs but also set the stage for future advancements in the vacuum packaging industry.

| Feature | Description | Benefit | Market Trend |

|---|---|---|---|

| Advanced Sealing Technology | Utilizes heat and pressure for a secure seal | Increased shelf life of packaged products | Rising demand for extended food preservation |

| Smart Packaging Solutions | Integration with IoT for real-time monitoring | Enhanced efficiency and reduced waste | Increasing focus on sustainability in food packaging |

| Customizable Machines | Modular designs to fit various product sizes | Flexibility for diverse packaging needs | Growing market for personalized packaging solutions |

| Energy-Efficient Models | Low power consumption designs | Lower operational costs | Trend toward eco-friendly manufacturing |

| Multi-Functionality | Combines vacuum packing with other processes like sealing | Reduction of processing time and labor | Demand for efficiency in production lines |

As the 138th Canton Fair approaches in 2025, innovations in vacuum packaging machine technology are expected to drive significant market growth. According to a report from MarketsandMarkets, the global vacuum packaging market is projected to grow from $24.5 billion in 2020 to $37.7 billion by 2025, at a compound annual growth rate (CAGR) of 9.1%. This growth is largely attributed to the increasing demand for packaged food products and the rising trend of sustainable packaging solutions.

Moreover, advancements in technology are enhancing the efficiency and versatility of vacuum packaging machines. The introduction of smart packaging features, such as real-time monitoring and automation, is set to revolutionize the food processing and packaging sectors. A study by Grand View Research indicates that the vacuum packaging machinery market alone is expected to witness substantial growth, projected to reach $5.1 billion by 2025. This will be propelled by heightened consumer awareness regarding food safety and longer shelf life, further emphasizing the significance of innovative packaging solutions in the modern marketplace.

At the 138th Canton Fair in 2025, the spotlight was on sustainable materials in vacuum packaging, showcasing significant innovations aimed at reducing environmental impact. Numerous exhibitors presented cutting-edge solutions that utilize biodegradable and recyclable materials, aligning with global initiatives to promote sustainability within the packaging industry. By integrating eco-friendly materials, these new vacuum packaging machines not only prolong the shelf life of products but also minimize waste, setting a precedent for future manufacturing practices.

**Tips for Businesses:** When considering sustainable packaging options, evaluate the material's lifecycle, including production, usage, and disposal. Incorporating materials that can decompose or be easily recycled can significantly enhance your brand's image while contributing to environmental preservation. Additionally, staying updated with innovations in machine technology will ensure your packaging processes are both efficient and eco-conscious.

The advancements in vacuum packaging technology also address consumer preferences for sustainably sourced products. As manufacturers adopt these innovative materials, they are likely to attract a growing segment of environmentally-aware consumers. The utilization of sustainable packaging not only fulfills regulatory requirements but also fosters customer loyalty, making it a wise investment for any forward-thinking business.

This bar chart illustrates the advancements in vacuum packaging materials showcased at the 138th Canton Fair in 2025. The data reflects the percentage of sustainable materials used in various types of vacuum packaging technologies.

As automation increasingly dominates the vacuum packaging industry, its impact on efficiency is profound. According to a recent report by Research and Markets, fully automated packaging systems can enhance production rates by up to 30%, significantly reducing labor costs and minimizing human error. Industry experts at the 138th Canton Fair in 2025 emphasized that automated vacuum packaging machines not only streamline workflows but also improve product shelf life, leading to increased customer satisfaction.

Tips for businesses looking to implement automation include investing in high-quality machinery that integrates seamlessly with existing production lines. Additionally, regular training for staff on the latest technologies can ensure that operators are well-equipped to manage automated systems effectively. Implementing IoT solutions can further enhance monitoring and predictive maintenance, ultimately optimizing performance.

Another critical insight shared at the fair highlighted that companies embracing automation have reported a reduction in packaging material waste by up to 20%, aligning with sustainability efforts. The integration of sensors and AI-driven analytics can enhance precision, allowing businesses to adapt packaging processes quickly in response to market demands. Embracing these innovations not only boosts efficiency but also positions companies competitively in an ever-evolving marketplace.

At the 138th Canton Fair in 2025, the vacuum packaging machine sector will showcase cutting-edge technologies from various leading brands. A comparative analysis of these exhibitors will highlight significant innovations and advancements that set them apart in a competitive market. Many brands are leveraging state-of-the-art features such as enhanced energy efficiency, user-friendly interfaces, and improved sealing techniques. These improvements not only elevate packaging processes but also address consumer demands for sustainability and convenience.

In recent years, Chinese manufacturers have established themselves as frontrunners in the vacuum packaging industry. Their commitments to rapid innovation and competitive pricing have allowed them to outpace global counterparts. As buyers from diverse regions, including Latin America and the Middle East, flock to the Canton Fair, they are eager to explore these advancements. The event serves as a pivotal platform for brands to engage with international customers and showcase their latest technologies, ultimately shaping the future of vacuum packaging machinery.