Leave Your Message

As the global packaging industry continues to evolve, the introduction of cutting-edge technologies is fundamentally transforming how products are packaged and delivered. According to a report by Smithers Pira, the global packaging market is projected to reach $ billion by 2024, driven by increasing consumer demand for convenience and sustainability.

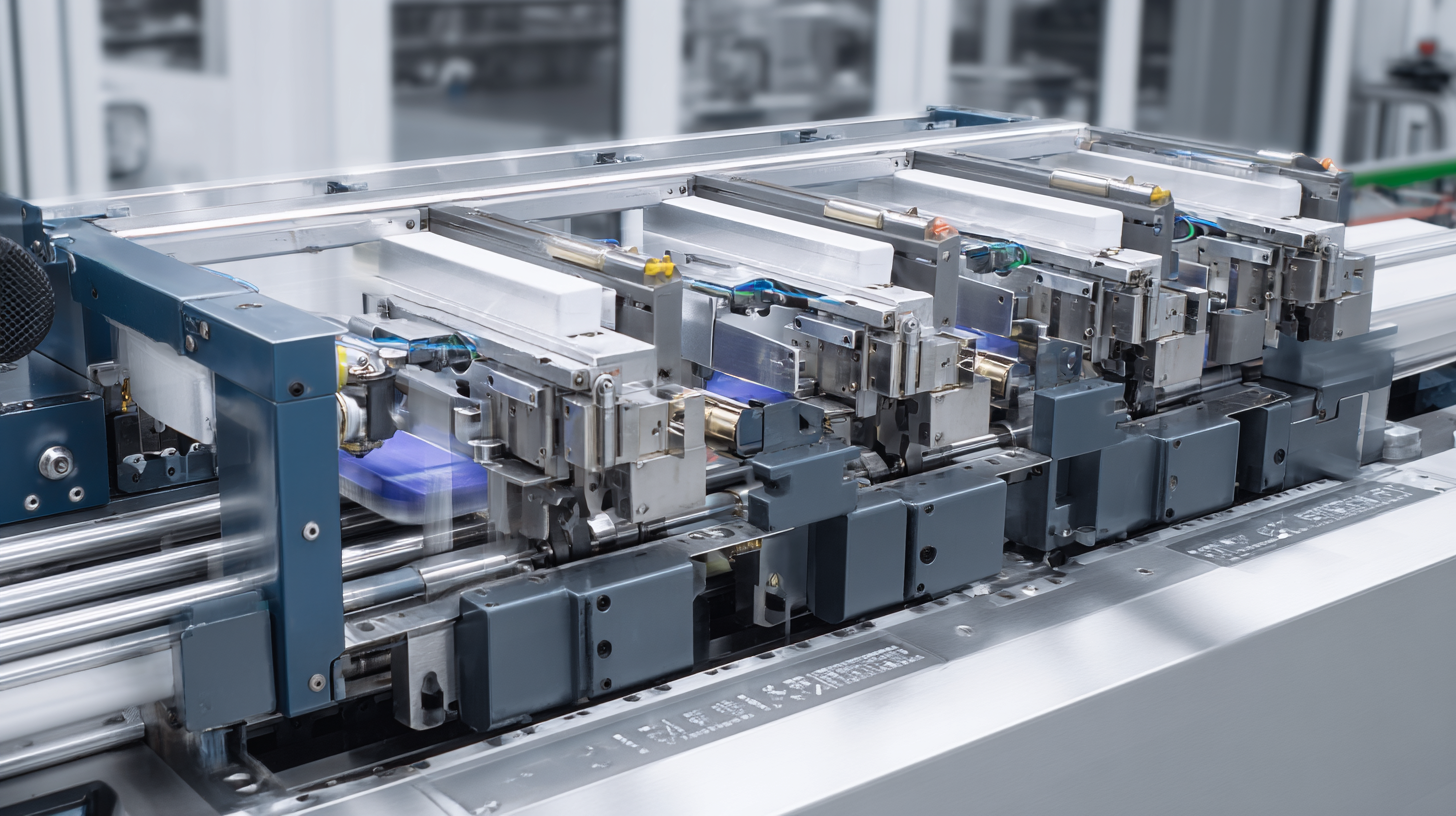

One of the key innovations within this landscape is the development of sophisticated machines designed specifically for packaging. These "Machine For Packaging" solutions incorporate advanced automation and robotics, enabling manufacturers to enhance efficiency, reduce material waste, and optimize production speed.

Moreover, with the rise of e-commerce, the need for flexible and adaptable packaging machines has never been more critical, further showcasing the importance of innovation within the industry.

As companies embrace these technological advancements, the potential for improved performance and reduced costs is set to revolutionize the packaging sector, meeting the diverse needs of the modern consumer.

Innovative packaging machines are transforming supply chain efficiency by streamlining processes and reducing costs. These advanced technologies, equipped with automation and smart features, enable faster packaging operations, which in turn accelerates the overall production cycle. By minimizing manual labor and human errors, businesses can achieve higher accuracy in packaging, reducing waste and ensuring that products are delivered to consumers in optimal condition.

Moreover, the integration of data analytics in packaging machines allows for real-time monitoring and adjustments. This capability helps manufacturers respond swiftly to demand fluctuations and maintain optimal inventory levels. As a result, companies are experiencing improved forecasting accuracy, leading to better resource allocation and reduced lead times. The impact of these innovative machines extends beyond the packaging line; it enhances the entire supply chain, ensuring that products reach the market more efficiently and effectively, meeting consumer expectations consistently.

| Machine Type | Efficiency Improvement (%) | Cost Reduction (%) | Time Saved (Hours/Week) | Return on Investment (ROI) |

|---|---|---|---|---|

| Automatic Case Packer | 30% | 20% | 15 | 150% |

| Robotic Palletizer | 40% | 25% | 20 | 180% |

| Vertical Form Fill Seal (VFFS) | 25% | 15% | 10 | 130% |

| Shrink Wrapping Machine | 35% | 22% | 12 | 160% |

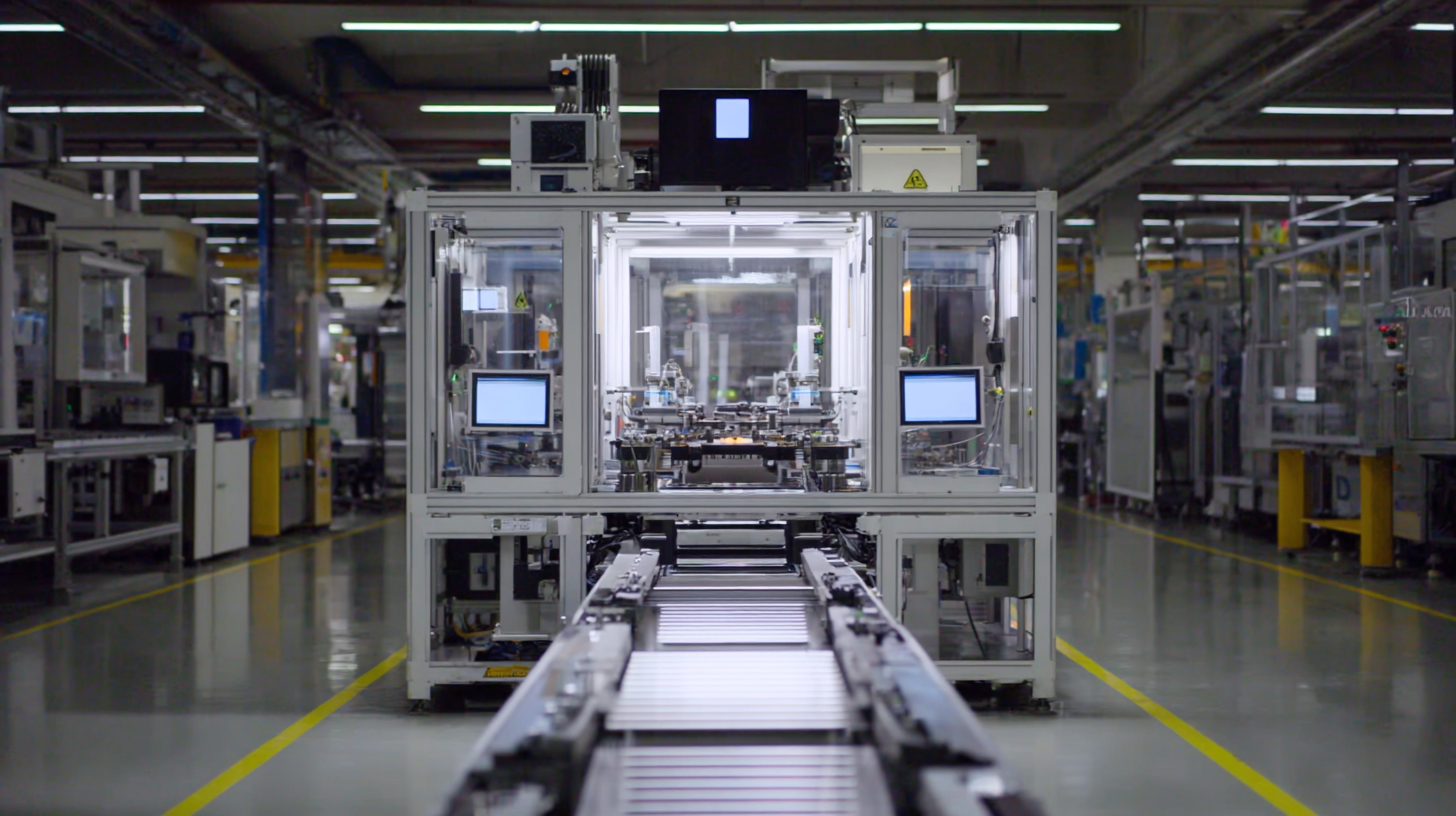

The packaging industry is undergoing a significant transformation driven by the adoption of automated packaging systems, which present substantial cost-saving benefits for manufacturers. As seen in recent trends, the deployment of intelligent technologies is revolutionizing how products are packaged and shipped. With automation, manufacturers are experiencing improvements in efficiency; for instance, some companies report enhanced management efficiency by over 10% and reductions in operational response times by as much as 50%. These advancements can translate to annual savings of millions in production costs, making automated systems an attractive investment.

Moreover, the fast-paced growth of the intelligent robotics market, projected to increase at a compound annual growth rate of 19.51%, highlights the urgency for manufacturers to adopt these innovations. As packaging technology evolves with smarter and more efficient solutions, industry players are embracing automation not only to enhance productivity but also to meet the increasing demands for supply chain transparency and traceability. With the continued support of policies favoring technological upgrades, the future of automated packaging systems appears promising, setting the stage for long-term growth and sustainability in the industry.

The role of smart technology in modern packaging solutions is becoming increasingly pivotal as the industry embraces AI-driven innovations and advanced testing methodologies. The rapid adoption of machine learning (ML) and artificial intelligence (AI) in testing systems is transforming the semiconductor testing landscape, enhancing both efficiency and accuracy. Companies leveraging AI can significantly improve their packaging processes, making them more adaptable to market demands.

Tips for implementation include investing in IoT and sensor technologies that provide real-time insights into packaging operations. This approach can lead to improved supply chain transparency and responsiveness, fulfilling consumer expectations for quality and sustainability. Furthermore, as the global AI packaging market anticipates a CAGR of 10.1%, businesses should prioritize strategies that align with technological advancements to stay competitive.

In addition, the increasing popularity of sustainable practices is pushing the paper pulp molding machine market to expand rapidly. As consumer preferences shift toward eco-friendly packaging, manufacturers must adapt by focusing on innovative solutions that cater to the growing demand for recyclable materials, thus ensuring they remain relevant in a dynamic marketplace.

The global market for fruits and vegetables processing is projected to grow significantly, reaching an estimated value of $36.995 billion by 2024 and expanding to approximately $63.609 billion by 2033, with a compound annual growth rate (CAGR) of 6.2%. This growth is driven not only by the increasing demand for processed foods but also by innovations in packaging machinery that enhance sustainability trends. As companies strive to minimize their environmental footprint, they are increasingly adopting advanced packaging technologies that align with eco-friendly practices.

Sustainable packaging solutions are becoming a crucial focus within the industry. Reports indicate a significant shift toward materials that reduce waste and promote recyclability. For instance, the sustainable pharmaceutical packaging market is expected to witness strong growth, with increasing demand for eco-friendly materials like paperboard, glass, and bioplastics. This trend reflects a broader movement across various sectors, as firms are urged to adopt practices that contribute to a circular economy, effectively reducing the environmental impact of packaging.

The industry is adapting, driven by both consumer preferences and regulatory pressures, ensuring that innovations in packaging machinery play a pivotal role in shaping a sustainable future.

To effectively measure the performance and return on investment (ROI) of innovative packaging machines, organizations should focus on both quantitative and qualitative metrics. Traditional benchmarks may include throughput rates, error rates, and machine uptime, which provide a clear picture of operational efficiency. However, integrating tools like the balanced scorecard can help create a multidimensional view by incorporating customer satisfaction and internal process metrics, thereby aligning machine performance with overall business objectives.

In addition, leveraging advanced analytics can provide insights into long-term performance. By analyzing historical data and drawing predictive insights, organizations can better assess the value generated by packaging machines and their potential for future contributions. This approach not only facilitates a deeper understanding of operational effectiveness but also enhances decision-making processes regarding technology investments—all crucial for keeping pace in the rapidly evolving packaging industry.