Leave Your Message

In recent years, the packaging industry has witnessed a significant transformation driven by technological advancements, particularly with the rise of the Vacuum Packing Machine. According to a report by MarketsandMarkets, the global food packaging market is projected to reach USD 500 billion by 2024, with vacuum packaging being one of the key contributors due to its ability to extend shelf life, reduce spoilage, and enhance product presentation. Businesses across various sectors, from food and beverage to pharmaceuticals, are increasingly adopting innovative vacuum packing solutions to streamline their packaging processes and improve efficiency.

The versatility and effectiveness of vacuum packing machines not only enhance product quality but also contribute to sustainability by minimizing waste. This blog will explore the cutting-edge applications of vacuum packing machines and how they are reshaping packaging strategies in today’s competitive market.

The versatility and effectiveness of vacuum packing machines not only enhance product quality but also contribute to sustainability by minimizing waste. This blog will explore the cutting-edge applications of vacuum packing machines and how they are reshaping packaging strategies in today’s competitive market.

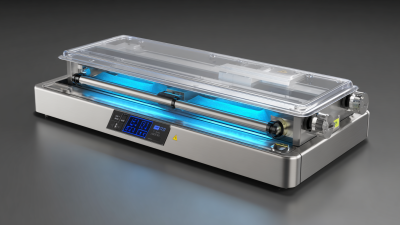

The evolution of vacuum packing machines has significantly reshaped the landscape of the packaging industry. Initially designed for preserving food, these machines now cater to a broader range of applications, enhancing the efficiency and longevity of products across various sectors. From electronics to pharmaceuticals, the ability to remove air and prevent oxidation has made vacuum packing an essential tool for maintaining product integrity.

Moreover, advancements in technology have allowed for more innovative designs and functionalities in vacuum packing machines. Modern devices feature programmable settings that cater to different materials and product types, which provides greater flexibility for manufacturers. Enhanced automation and integration with supply chain processes have further optimized packaging efficiency, allowing companies to adapt quickly to changing market demands without compromising on quality. As industries continue to embrace sustainability, the recyclability of vacuum packs and the reduction of food waste further highlight the transformative impact of these machines on packaging strategies.

| Application Area | Benefits | Innovations | Usage Trends |

|---|---|---|---|

| Food Industry | Extended shelf life, preservation of freshness | Smart sensors for optimal sealing | Growing demand for vacuum-sealed meal kits |

| Medical Supplies | Enhanced sterilization and hygiene | Automated sealing for surgical kits | Increase in demand due to regulatory standards |

| Electronics Packaging | Protection from moisture and static | Anti-static vacuum bags | Rapid growth in e-commerce shipments |

| Retail and Consumer Goods | Attractive packaging, space-saving | Eco-friendly materials for vacuum pouches | Shift towards sustainable packaging solutions |

Vacuum packing technology has evolved beyond traditional food preservation, leading to innovative applications that enhance packaging strategies across various industries. One notable application is in the medical field, where vacuum packing helps in sterilizing and preserving surgical instruments. According to a report by MarketsandMarkets, the global medical packaging market is projected to reach $50.3 billion by 2025, with vacuum packaging playing a significant role in ensuring the safety and longevity of medical supplies.

Another promising application of vacuum packing is in the consumer electronics sector. Vacuum-sealed packaging protects sensitive electronic components from moisture and contaminants, significantly reducing failure rates. Research indicates that nearly 70% of electronics failures are due to environmental factors, making effective packaging critical. Furthermore, a study from Allied Market Research forecasts that the electronics packaging market will hit $30 billion by 2027, emphasizing the growing reliance on vacuum technology for safeguarding high-value items.

The rise of e-commerce has also driven innovative vacuum packing applications in logistics. By eliminating excess air, vacuum packing reduces shipping volumes and costs, leading to more efficient supply chains. According to the International Council on Clean Transportation, efficient packaging can decrease carbon emissions associated with shipping by up to 30%. As businesses seek sustainable solutions, vacuum packing stands out as a transformative strategy to enhance both ecology and economy in packaging.

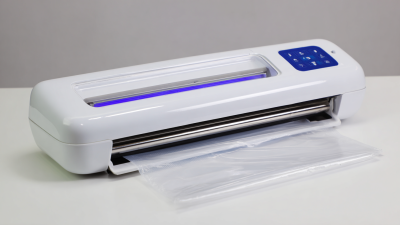

Vacuum packing machines are revolutionizing the way we think about food preservation, offering a myriad of benefits that extend the shelf life of products while maintaining their quality. By removing air from packaging, these machines create a barrier against oxygen, moisture, and contaminants, which are common culprits in spoilage. This innovative approach not only slows down the degradation of food items but also helps in retaining flavors and nutrients, ensuring that consumers enjoy fresh and delicious products long after their packaging.

Moreover, the implications of vacuum packing extend beyond mere preservation; they also facilitate better inventory management for businesses. With extended shelf life, products can be stored for longer periods without the risk of spoilage, reducing waste and allowing for more efficiently organized stock. This is particularly crucial for restaurants and grocers, as the ability to minimize food wastage translates into significant cost savings. The adaptability of vacuum packing machines means they can handle various food types, from meats and cheeses to fruits and vegetables, making them essential tools for modern food preservation strategies that prioritize sustainability and quality.

Vacuum packing plays a pivotal role in sustainable packaging solutions, significantly reducing food waste and extending product shelf life. Recent data from the Food and Agriculture Organization indicates that up to one-third of all food produced for human consumption is wasted, translating to about 1.3 billion tons annually. By utilizing innovative vacuum packing machines, businesses can dramatically decrease their environmental impact. These machines eliminate air from packaging, thereby reducing oxidation, preventing spoilage, and extending freshness without the need for chemical preservatives.

Tip: When implementing vacuum packing, consider using biodegradable materials or recyclable options to further enhance the sustainability of your packaging strategy. This not only meets consumer demand for eco-friendly practices but also aligns with a growing regulatory focus on reducing plastic waste.

Moreover, vacuum packing can cater to various industries, including food and pharmaceuticals, translating to cost savings and improved efficiency. A report by Research and Markets anticipates the global vacuum packaging market will reach $30 billion by 2024, driven by the increasing demand for sustainable alternatives. Companies that adopt vacuum packing technologies not only benefit from enhanced product protection but also contribute to a more sustainable future, demonstrating their commitment to corporate social responsibility.

Tip: Regularly assess your vacuum packing processes and materials to ensure they align with the latest sustainability practices. Incorporating technology that monitors freshness can also help optimize performance and reduce waste.

This chart illustrates the various applications of vacuum packing machines across different industries, highlighting their impact on sustainable packaging solutions.

The vacuum packing industry is poised for a significant transformation, driven by the integration of smart technology and automation. According to a report by Grand View Research, the global vacuum packing market is expected to reach USD 20.25 billion by 2025, with a CAGR of 4.8%. This growth is largely attributed to the rising demand for extended shelf life and enhanced food safety, fueling innovations in packaging solutions. Smart vacuum packing machines equipped with IoT capabilities allow for real-time monitoring and analytics, ensuring optimal bag sealing and product integrity.

Moreover, automation in vacuum packing processes is reshaping how companies operate. Industry analysis shows that automated vacuum packing systems can improve production efficiency by up to 30%, reducing labor costs while increasing throughput. The use of robotics and AI in packaging lines enables businesses to adapt quickly to fluctuating market demands and customize their packaging strategies. As these technologies continue to evolve, businesses are presented with opportunities to enhance their competitive edge, ensuring that they meet consumer expectations for quality and sustainability in packaging.