Leave Your Message

In today's competitive business landscape, the efficiency of packaging processes can significantly influence a company's bottom line. A well-chosen packing machine not only enhances productivity but also offers a return on investment that is hard to overlook. According to a report by Research and Markets, the global packaging machinery market is projected to grow to $45.24 billion by 2027, driven largely by increased automation and demand for advanced packaging solutions across various industries. Investing in a packing machine may very well be a pivotal move for companies aiming to streamline operations and meet consumer demand.

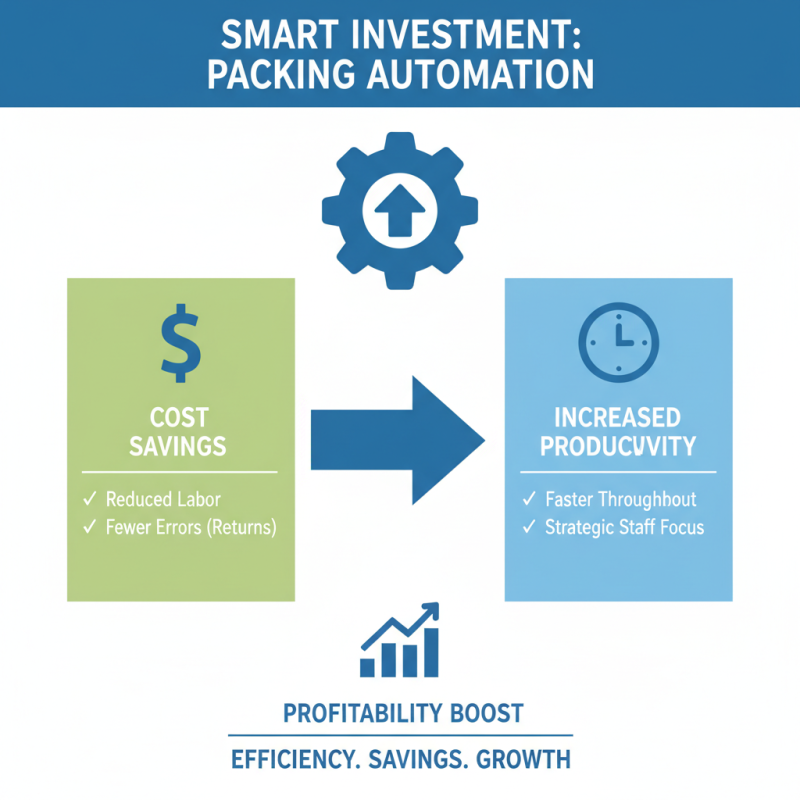

The benefits of integrating a packing machine into business operations extend beyond mere speed; they also encompass consistency and quality assurance. A study by Smithers Pira highlighted that automation in packaging could reduce labor costs by up to 30%, allowing businesses to reallocate resources to other critical areas. Furthermore, with the rise of e-commerce and changing consumer preferences for sustainable packaging, companies equipped with advanced packing machinery can better adapt to market trends, ensuring they remain competitive. Therefore, investing in a packing machine is not just a step towards operational efficiency—it's a strategic decision that can pave the way for long-term business success and resilience.

In today's fast-paced business environment, efficient packaging is a crucial factor that can significantly influence a company's success. According to a recent study by the Packaging Association, nearly 60% of consumers say that the quality of packaging reflects the quality of the product inside. This perception underscores the necessity for businesses to invest in modern packing solutions that not only enhance aesthetics but also streamline operational procedures.

Efficient packaging eliminates bottlenecks in the supply chain and dramatically reduces labor costs, as automated systems can operate rapidly and consistently, ensuring deadlines are met and customer satisfaction is maintained.

One important tip for businesses considering packaging investments is to assess the long-term return on investment (ROI). While upfront costs for packing machines may seem daunting, the savings gained through reduced labor costs, improved efficiencies, and fewer errors often pay off handsomely. Additionally, automated packaging can minimize material waste, further enhancing profitability. A report from Smithers Pira indicates that companies adopting advanced packaging technologies can achieve up to a 30% reduction in material costs, demonstrating the tangible benefits of such investments.

Finally, it’s vital to stay informed about current trends in packaging sustainability and innovation. The preference for eco-friendly packaging has increased, with over 70% of millennials expressing a willingness to pay more for sustainable products. This shift in consumer behavior presents an opportunity for businesses to enhance their brand image while contributing positively to the environment. Investing in advanced packing machines that accommodate sustainable materials can not only meet market demands but also position your company as a forward-thinking leader in the industry.

When considering the type of packing machines suitable for your business, it's important to recognize the diverse needs across various industries. For instance, food and beverage companies often rely on vertical and horizontal form fill seal machines that enhance efficiency and product shelf life. These machines automate the process of filling, sealing, and packaging, which can significantly reduce labor costs and ensure consistency in product presentation. Similarly, for the cosmetic and pharmaceutical sectors, blister packing machines are essential, providing optimal protection for individual doses while maintaining the aesthetic appeal of the packaging.

Tips: Before investing in a packing machine, assess your production volume and product specifications. Different machines cater to varied production scales; selecting one that matches your needs can optimize efficiency. It’s also wise to consider the flexibility of the machinery—can it accommodate future product lines without hefty modifications?

In the e-commerce realm, automated packing solutions like case sealers and stretch wrappers are revolutionizing how products are shipped. These machines not only protect goods during transit but also enhance the speed of order fulfillment, a key factor in customer satisfaction. Businesses should evaluate their packing processes to determine which machines can streamline operations while maintaining a focus on sustainability in materials, where applicable.

Tips: Don't overlook the importance of maintenance and training when investing in packing machines. Ensuring your staff is adequately trained can prevent costly downtime and inefficiencies, making the most of your investment.

Investing in a packing machine can significantly enhance your business's efficiency and profitability. A cost-benefit analysis reveals that the upfront expense of purchasing a packing machine can be offset by the long-term savings it offers. With increased speed and accuracy in packing, businesses can reduce labor costs and minimize errors that lead to product returns. Additionally, automation allows staff to focus on more strategic tasks rather than manual packing, resulting in better resource allocation.

Tips for evaluating the cost-effectiveness of a packing machine include calculating the labor hours saved per week by automating the packing process. Understand your volume needs: a machine should be able to handle your current output while allowing for future growth. Moreover, consider the total cost of ownership by factoring in maintenance and operational costs to ensure maximum return on investment.

A successful packing machine investment also depends on choosing the right type for your products. Different machines cater to varying packaging options and materials, which can impact your operational efficiency. Researching options and understanding your product requirements can lead to informed decisions that enhance overall performance and customer satisfaction.

Investing in a packing machine can significantly enhance product shelf life and safety, providing businesses with a competitive advantage in today’s market. Automation in packaging ensures that products are sealed efficiently, reducing the exposure to external contaminants that can compromise quality. For instance, a well-sealed package minimizes the risk of air and moisture infiltration, which are known factors that can lead to spoilage or degradation of food and other perishable goods. As a result, businesses can ensure that their products remain fresh for longer periods, meeting customer expectations for quality and safety.

Moreover, automated packing systems are designed to maintain consistent quality and precision during the packaging process. This consistency is crucial for adhering to industry regulations and safety standards, as any lapses in packaging can lead to serious consequences. By investing in a packing machine, businesses can reduce human error associated with manual packaging, thus enhancing overall product integrity. Not only does this safeguard the health of consumers, but it also helps to build brand trust and loyalty, which are essential for long-term success in any industry. With the growing emphasis on safety and quality in consumer products, the benefits of automation in packaging cannot be overstated.

| Dimension | Value |

|---|---|

| Average Product Shelf Life Increase | 20-30% |

| Reduction in Product Waste | Up to 15% |

| Time Saved in Packing Process | 40% |

| Cost Reduction in Labor | 25% |

| Increase in Production Capacity | 50% |

| Improvement in Packaging Consistency | 90% |

| Return on Investment (ROI) Period | 6-12 months |

When selecting the right packing machine for your business needs, it is essential to assess your specific product requirements and operational goals. Different packing machines vary in terms of speed, automation level, and the types of materials they handle. For instance, if your business deals with fragile items, investing in a machine that offers cushioning or protective packaging features is critical. Understanding the dimensions and weight of your products will also help you choose a machine that can accommodate various sizes and shapes effectively.

Additionally, consider the scalability of the packing machine. As your business grows, your packaging needs may evolve, so it is wise to opt for equipment that allows for future upgrades or modifications. Automation is another crucial factor; while fully automated machines can increase efficiency, semi-automated options might be more suitable for smaller operations that require flexibility. Evaluating these aspects will ensure that you select a packing machine that not only meets your current needs but also supports long-term growth and efficiency for your business.