Leave Your Message

In today's fast-paced business environment, operational efficiency is more crucial than ever. One of the key tools that can significantly enhance productivity is the Label Printer Machine. This device not only streamlines the labeling process but also helps businesses maintain better organization and inventory control. With the ability to produce high-quality labels quickly, a label printer can save valuable time that employees can use for more critical tasks, ultimately contributing to improved overall efficiency.

Moreover, a Label Printer Machine offers a cost-effective solution for companies of all sizes. By reducing the time spent on labeling tasks and minimizing errors associated with manual processes, businesses can lower operational costs and improve accuracy in their logistics and inventory management. As customer demands for fast and reliable delivery services increase, having an effective labeling solution becomes vital to meeting these expectations and enhancing customer satisfaction.

Incorporating a Label Printer Machine into your business operations can lead to significant improvements in workflow and productivity. Whether you're in retail, manufacturing, or shipping, investing in this powerful tool is a strategic move that can transform how you handle labeling tasks, ensuring that your business stays competitive in a rapidly evolving marketplace.

In today's fast-paced business landscape, operational efficiency is paramount, and label printers have emerged as invaluable tools for organizations across various industries. According to a report by the International Data Corporation (IDC), companies that implement automated labeling processes can improve their operational efficiency by up to 30%. This statistic illustrates the significant impact that label printers can have on streamlining business functions, from inventory management to shipping logistics.

Label printers not only enhance productivity but also reduce human error. Manual labeling can lead to misidentification of products, resulting in costly mistakes. A study by the American National Standards Institute (ANSI) found that 88% of all labeling errors stem from human oversight. By utilizing a label printer, businesses can ensure accuracy and consistency in their labeling, which is essential for maintaining inventory accuracy and customer satisfaction.

Tips for maximizing the effectiveness of your label printer include regularly updating your label designs to reflect your brand's identity and ensuring your printers have the latest software for optimal performance. Additionally, consider integrating your label printer with your inventory management system for seamless operations. This integration can further enhance efficiency, as real-time data updates allow for quicker responses to stock levels and sales trends, ultimately driving business growth.

When considering the types of label printers suitable for different business needs, it's essential to understand the unique requirements of your operations. For small businesses that focus on shipping, a direct thermal label printer is an economical choice. These printers produce high-quality labels without the need for ink, making them a budget-friendly option for short runs. They are ideal for producing shipping labels that can withstand most conditions, perfect for e-commerce businesses managing order fulfillment.

On the other hand, if your business requires a more versatile solution, a thermal transfer label printer might be the way to go. This type of printer uses a ribbon to produce durable and high-resolution labels that are resistant to scratches, heat, and water. This durability makes them suitable for industries like food and beverage, manufacturing, and logistics, where label longevity is crucial. Additionally, they can accommodate a wider variety of label materials, which enhances their adaptability to different labeling needs.

Tip: When selecting a label printer, consider the volume of labels you need to print regularly. High-volume operations may benefit from faster, more robust models that can handle large batches efficiently. Tip: Always factor in the cost of consumables, such as label rolls and ribbons, into your overall budget. This will ensure better long-term cost management and prevent unexpected expenses down the line.

Investing in a label printer machine can significantly enhance workflow efficiency and productivity in various business contexts. According to a report by the International Data Corporation (IDC), organizations that incorporate automated labeling systems can see up to a 25% increase in operational efficiency. This uplift largely stems from the reduction of manual labor involved in labeling processes, which is often prone to human error and time-consuming tasks such as handwriting or printing labels individually. By streamlining these operations, businesses can allocate their resources more effectively, allowing employees to focus on higher-value tasks.

Moreover, a survey conducted by the Association for Automatic Identification and Mobility (AIM) revealed that 75% of companies that have adopted label printing solutions reported improved accuracy in inventory management and tracking. Efficient labeling minimizes mislabeling and enhances traceability, which is crucial in fast-paced environments such as retail, logistics, and manufacturing. Through timely and accurate labeling, businesses can expedite their workflow processes, leading to improved customer satisfaction and reduced operational bottlenecks. Therefore, the integration of a label printer machine not only optimizes day-to-day operations but also contributes toward a more agile and responsive business model.

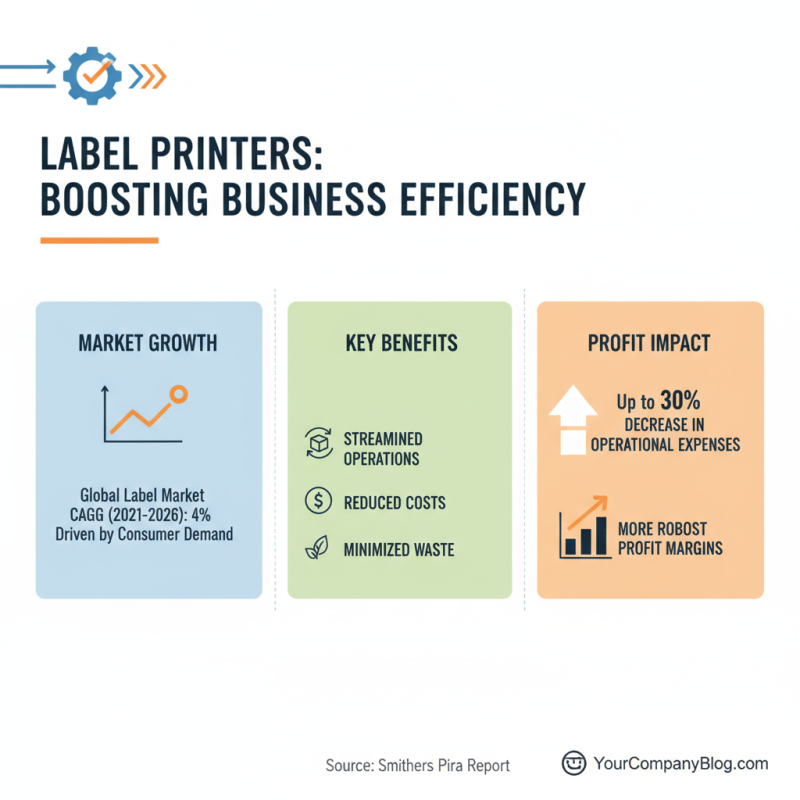

Investing in a label printer machine can significantly enhance business efficiency, particularly when it comes to cost-effectiveness. According to a recent report by Smithers Pira, the global label market is projected to grow at a compound annual growth rate (CAGR) of 4% from 2021 to 2026, indicating a rising demand for labeling solutions that can keep pace with consumer needs. Businesses that adopt label printing technologies can streamline their packaging operations, reduce labor costs, and minimize material waste, ultimately leading to more robust profit margins. In fact, organizations that have integrated automated labeling processes have noted up to a 30% decrease in operational expenses.

Tips: When selecting a label printer, consider the type of labels you regularly need. Different printers excel in different applications, such as thermal transfer or direct thermal printing. Conducting a needs assessment based on your business volume can help ensure you choose the right technology.

Furthermore, investing in in-house label printing can eliminate the need for outsourcing, which often incurs additional costs and delays. Industry data suggests that companies can save between 20-50% by producing labels in-house versus purchasing them from third-party suppliers. In-house printing also allows for greater flexibility, enabling businesses to quickly adapt to changing product lines or promotional campaigns.

Tips: Regularly assess your label inventory and printing requirements. Keeping a close eye on your usage patterns can help you avoid unexpected shortages and maintain seamless operations, ensuring you're always ready to meet customer demand.

Integrating label printers with existing business technology systems can significantly enhance efficiency and streamline operations. When label printers are incorporated into a business's technological ecosystem, they enable seamless printing of labels directly from inventory management systems, shipping software, or customer relationship management tools. This integration reduces the chances of human error and minimizes manual input, leading to faster processing times and increased productivity.

Tips: Before integrating label printers, assess your current technology stack to identify potential compatibility issues. Ensure that the printer you choose can easily communicate with your existing software solutions to avoid disruption in workflow. Additionally, consider cloud-based printing solutions, which can provide you with the flexibility to print labels from anywhere, further enhancing your efficiency.

Another advantage of integrating label printers is the customization they offer. Businesses can create labels that are tailored to specific needs without relying on external printing services, which can often be costly and time-consuming. This not only protects sensitive information but also allows for quick adjustments to label designs as needed.

Tips: Regularly review your label designs and workflows to ensure they meet current business demands. This practice can help you adapt to changes in your market or product offerings and ensure your labeling processes remain efficient and relevant.