Leave Your Message

In today's fast-paced world, the importance of efficient labeling cannot be overstated. A Label Printer Machine has transformed the way businesses manage their products and inventory. According to Richard Layton, a well-known expert in the printing industry, "Label Printer Machines bridge the gap between productivity and accuracy." This quote highlights the essential role these machines play in modern operations.

Label Printer Machines offer a variety of functionalities. They can print different labels for shipping, barcodes, and product tags. These machines enhance speed and precision, reducing manual errors. However, some users struggle to optimize their features fully. Understanding the technology can be challenging, especially with numerous models available.

Yet, with their advantages, Label Printer Machines come with considerations. Maintenance might be overlooked, leading to reduced efficiency. Moreover, selecting the right machine can be overwhelming. A thoughtful approach can help businesses maximize their investment. Overall, the right Label Printer Machine can streamline processes and elevate operational success.

A label printer machine is a device that creates adhesive labels for a variety of uses. It can print text, graphics, and barcodes. Such printers are essential in many settings. You’ll find them in offices, warehouses, and retail spaces. Their compact design makes them easy to use and store.

These machines work by converting digital designs into physical labels. Users typically create the label designs using software. The printer then feeds special label paper through its mechanism. The print head heats up and transfers ink onto the label. This process may sound simple, but results can vary. Sometimes, labels may smudge or peel off. The quality of labels can depend on the paper used and the printer settings. Users may need to experiment with different materials to find the best fit.

Label printers come in different types. Thermal printers use heat to produce images. Inkjet printers, on the other hand, spray ink onto the label surface. Each type has its advantages and drawbacks. While thermal printers are great for long-lasting labels, inkjet models offer vibrant colors. Understanding the differences is vital for effective label creation. Make sure to reflect on your needs before making a choice.

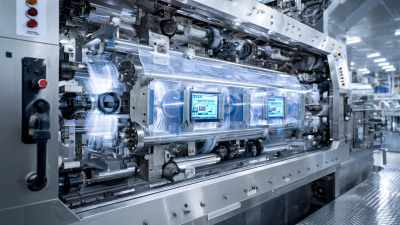

A label printer machine is essential in various industries. Understanding its key components helps in selecting the right one. The main parts include the print head, media, and control panel. The print head heats up to transfer ink onto the label material. This process is crucial for producing clear, high-quality prints. According to research by Smithers Pira, the global label printer market is projected to reach $45 billion by 2026, indicating its growing importance.

The media, typically rolls or sheets of label stock, is another vital component. Depending on the application, businesses choose different adhesives and finishes. For instance, a warehouse may require durable labels, while a retail store opts for vibrant designs. The control panel allows users to adjust settings, but it can be complex for some operators. A survey from the Label Manufacturers Association shows that 30% of users feel challenged by the technology.

Regular maintenance of these components is necessary for optimal performance. Users often overlook this, leading to printer malfunctions. Furthermore, improper media settings can cause poor print quality, wasting both time and resources. It's crucial to prioritize training for staff. Addressing these issues can prevent significant operational disruptions. The label printing industry continues to evolve, pushing for innovations that emphasize efficiency and clarity.

Label printers come in various types, each tailored for specific applications. Thermal transfer printers are popular in warehouses. They use heat to transfer ink from a ribbon onto labels. This method produces durable, high-quality prints suitable for shipping labels and product tags. Another type is direct thermal printers, which create images through heat-sensitive paper. These printers are common for receipt printing, like those found in retail stores.

Inkjet label printers are also prevalent. They offer vibrant color prints. Businesses use them for custom labels, often in small quantities. A downside is that ink can smudge if exposed to moisture. Laser label printers, on the other hand, provide fast printing speeds. They are ideal for high-volume needs, making them great for offices. However, the initial investment can be higher than other printer types.

Selecting the right label printer depends on the user's specific needs. Some may prioritize print quality, while others focus on speed and volume. The cost-effectiveness of a printer could lead to overspending if not carefully evaluated. Each type of printer has its advantages and limitations, and understanding these nuances is vital for making informed decisions.

| Type of Label Printer | Technology | Typical Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Thermal Transfer Printer | Thermal Transfer | Product labels, medical labels, packaging | High durability, wide variety of label materials | Higher initial cost, requires ribbon replacements |

| Direct Thermal Printer | Direct Thermal | Shipping labels, receipts, coupons | Lower upfront cost, minimal maintenance | Less durable, sensitive to heat and light |

| Inkjet Label Printer | Inkjet | High-quality color labels, photographs | Vivid color output, suitable for small runs | Slower print speeds, ink cost can be high |

| Laser Label Printer | Laser | Professional-grade labels, barcodes | Fast printing speed, high print quality | Higher equipment cost, larger footprint |

| Digital Label Printer | Digital printing | Custom labels, low-volume print runs | Flexibility in designs, quick turnaround | Can be expensive for large runs, limited media types |

Label printer machines are essential devices in many industries. They allow users to produce high-quality labels quickly and efficiently. The working mechanism is straightforward yet effective.

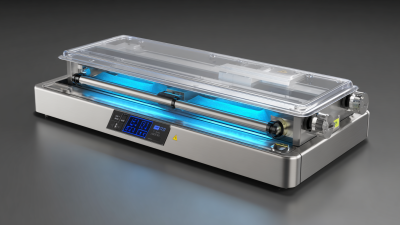

A label printer typically uses thermal transfer technology or direct thermal printing. In thermal transfer printing, heat is applied to a ribbon, transferring ink onto the label material. This results in durable and vibrant labels. On the other hand, direct thermal printing uses heat-sensitive materials that turn black when heated. Both methods have their own advantages.

**Tips:** Choose the right type of labels for your projects. Some labels resist moisture and heat, while others may not. Conduct tests to find the best option.

When operating a label printer, ensure the print head is clean. Dust and debris can affect the print quality. Regular maintenance is essential, but many users overlook this aspect.

**Tips:** Always check the ink or ribbon levels. Running low can lead to faded prints, which may require reprints. Keep an eye on your supplies for smooth operation.

Label printer machines are versatile tools widely used in various industries. They can generate custom labels quickly and efficiently. This capability streamlines the packaging and organization processes. In warehouses, they label boxes clearly. It prevents confusion and speeds up inventory management. A well-printed label can enhance professionalism too.

Many businesses benefit from label printers. Retail shops use them for pricing and barcode labels. This saves time compared to handwritten tags. In healthcare, they help to label medicines and supplies. It ensures safety and compliance with regulations. However, some may overlook maintenance. A lack of upkeep can lead to print quality issues over time.

Home users also find value in label printers. They can personalize items effortlessly. Organizing home office materials becomes simpler. However, it’s easy to create clutter if labels are overused. Thoughtful labeling is key to maintaining order. Balancing creativity with functionality is essential. Labels should enhance clarity, not overwhelm.