Leave Your Message

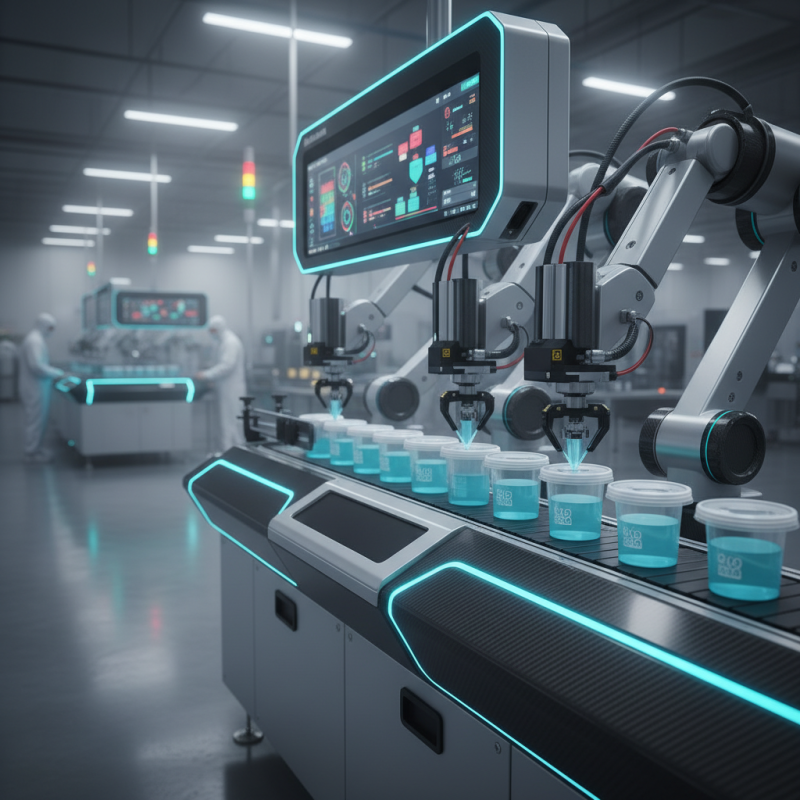

In today's manufacturing landscape, efficiency is key. A machine for packaging plays a crucial role in this process. These machines streamline operations, saving time and reducing labor costs. They automate tasks that were once manual, like filling, sealing, and labeling.

However, not all machines for packaging are perfect. Some may struggle with varied product sizes. Others might have frequent downtimes, causing delays. It’s essential to understand that while machines enhance productivity, they also require regular maintenance and adjustment.

Choosing the right machine for packaging is vital. The features and capabilities vary greatly across models. Companies must evaluate their specific needs carefully. In this evolving industry, embracing technology also means acknowledging its limitations and planning for ongoing improvements.

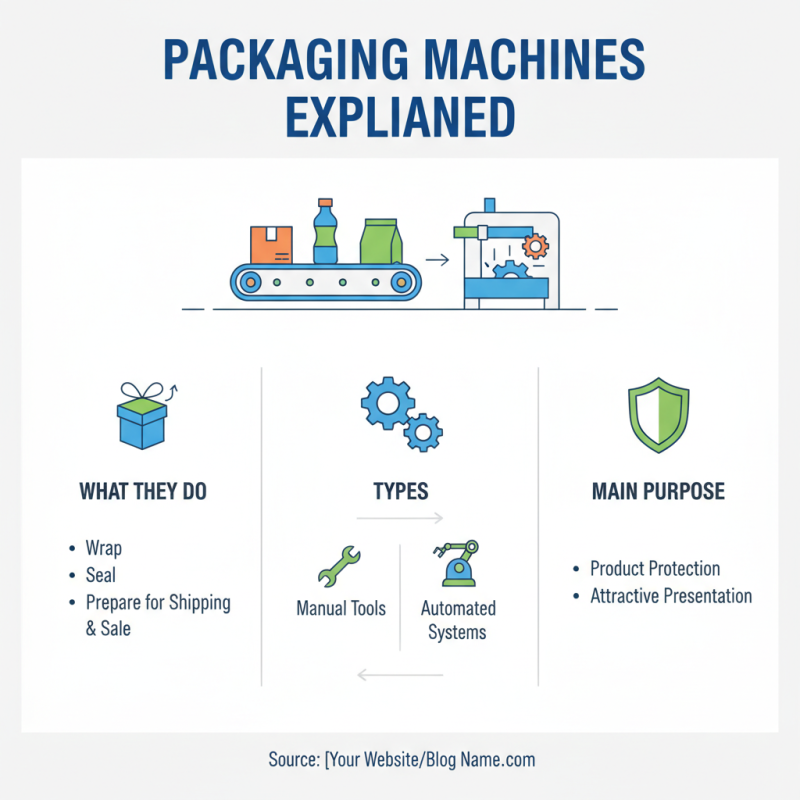

A packaging machine is a device designed to wrap, seal, and prepare products for shipping and sale. These machines come in various forms, depending on the type of product and packaging required. They can be as simple as manual tools, or as complex as automated systems that integrate with production lines. The main purpose is to ensure that products are protected and presented attractively.

These machines often use advanced technology to enhance efficiency. For example, some packaging machines can adjust to different sizes and materials. This flexibility can save time and reduce waste. However, the complexity of automation raises questions. Are operators adequately trained? Is there a risk of malfunction? These considerations are critical for maintaining productivity.

In practice, not every packaging machine meets every need perfectly. Some machines struggle with irregular shapes or delicate items. This can lead to product damage. It's vital to continuously assess performance and seek improvements. A good packaging machine should not only optimize speed but also adapt to various challenges.

Packaging machines play a crucial role in various industries. They streamline processes and ensure products are ready for distribution. Several types of packaging machines are commonly used today.

One type is the vertical form fill seal machine. This equipment forms bags from a flat roll of film. Then, it fills them with products and seals them. It's often used for powders and granules. Another type is the horizontal flow wrapper. This machine wraps items in a continuous flow. It's great for snacks and small boxes. These machines can also adjust packaging sizes, which adds versatility.

However, there are challenges in using these machines. Adjustments often require skilled operators. Maintenance can be time-consuming and costly. Not all machines suit every product. It's crucial to choose a machine that fits specific needs. Automation might lead to oversight and fewer quality checks. Balancing efficiency and quality is a constant concern.

Packaging machines play a critical role in modern manufacturing. They automate the packing process, improving efficiency and consistency. When discussing packaging machines, several key components stand out.

One essential element is the filling system. This part ensures accurate measurement and placement of products into containers. The filling system can vary depending on the product type. It might include pumps or augers for liquids and solids. An inefficiency here can lead to underfilled packages, impacting customer satisfaction.

Next is the sealing mechanism. It secures the package to preserve freshness and prevent contamination. Different sealing methods exist, such as heat sealing or adhesive. However, sometimes these methods can fail. An improperly sealed package might compromise its integrity. It's crucial for manufacturers to regularly check these components to maintain quality and prevent waste.

Lastly, the labeling system cannot be overlooked. Accurate labeling promotes brand credibility and compliance with regulations. If labels are misprinted or applied incorrectly, it could mislead consumers. Manufacturers should prioritize regular maintenance and quality checks to avoid these pitfalls. Each component works together to optimize the packaging process, but flaws can lead to bigger issues if not addressed promptly.

A packaging machine is an essential tool in the manufacturing industry. It automates the packaging process, making it faster and more efficient. These machines can handle various products, from food to industrial goods. In 2020, the global packaging machinery market was valued at approximately $45 billion, demonstrating its importance in modern production lines.

The operation of a packaging machine can be broken down into several clear steps. Initially, the product is fed into the machine. Sensors detect the products and ensure proper spacing. Next, the machine forms the packaging material. This can involve cutting, folding, or shaping materials like plastic or cardboard. After that, the product is placed within the packaging. Adhesives or heat sealing methods secure the package. Lastly, the finished product is labeled and prepared for shipment.

Despite advancements, challenges remain. Some machines have limitations in dealing with varied product shapes and sizes. This can lead to inefficiencies. Moreover, maintenance is crucial. Regular checks prevent breakdowns, yet many manufacturers overlook this aspect. Improvements are always welcome in this sector, highlighting areas for growth.

| Step | Description | Equipment Used | Duration |

|---|---|---|---|

| 1 | Product Feeding | Conveyor System | 2 minutes |

| 2 | Filling | Filling Machine | 3 minutes |

| 3 | Sealing | Sealing Machine | 2 minutes |

| 4 | Labeling | Labeling Machine | 1 minute |

| 5 | Quality Control | Inspection System | 3 minutes |

| 6 | Packaging | Packaging Machine | 4 minutes |

| 7 | Final Inspection | Manual Check | 2 minutes |

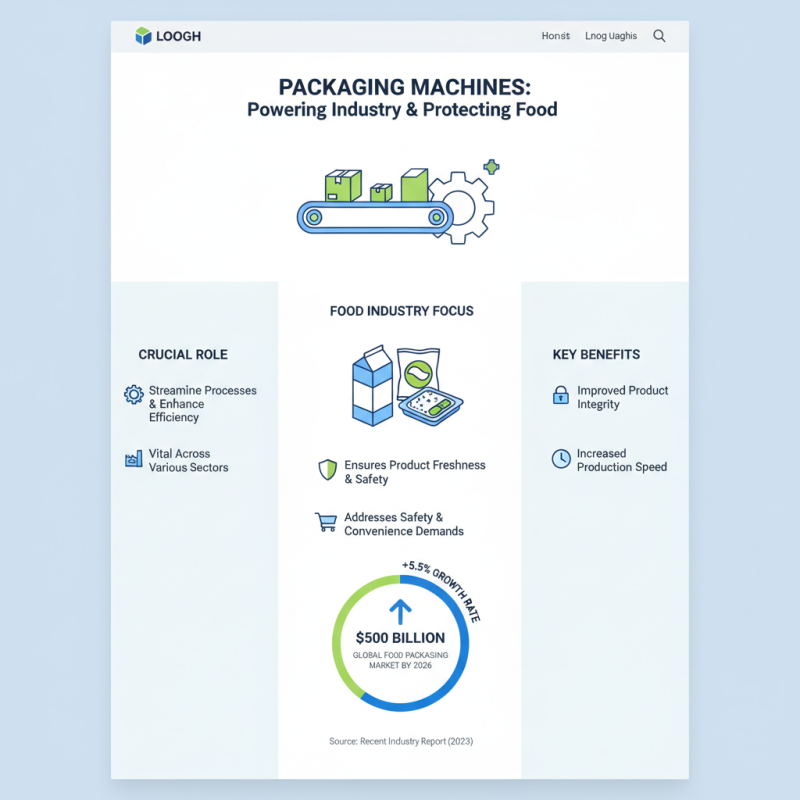

Packaging machines play a crucial role in various sectors, streamlining processes and enhancing efficiency. In the food industry, these machines ensure products remain fresh and safe. According to a recent industry report, the global food packaging market is projected to reach $500 billion by 2026, growing at a rate of 5.5%. This growth underscores the increasing demand for specialized packaging solutions that address safety and convenience.

In pharmaceuticals, packaging machines are vital for maintaining product integrity. With strict regulations, pharmaceutical companies rely on advanced machinery to ensure compliance and quality. The pharmaceutical packaging market is expected to grow to $120 billion by the end of 2025. However, challenges remain, particularly in adapting to new regulations and ensuring that machines keep pace with rapid technological advancements.

The cosmetics industry also benefits significantly from packaging machinery. Attractive packaging can enhance consumer appeal. A survey showed that over 70% of consumers consider packaging when making buying decisions. Nevertheless, companies face a dilemma: balancing sustainability with aesthetic appeal. Many packaging machines are not yet optimized for eco-friendly materials, forcing brands to rethink their strategies continuously.