Leave Your Message

In the booming food preservation industry, mastering the can sealer machine has become essential for both small-scale home canners and large manufacturers alike. According to the latest report by the Food Packaging Association, the global canned food market is projected to reach $98.64 billion by 2025, underscoring the rising demand for effective canning solutions. As consumers increasingly seek wholesome, home-canned options, understanding how to properly operate a can sealer machine is critical for ensuring product quality and safety.

This step-by-step tutorial is designed to equip beginners with the skills and confidence needed to navigate their can sealer machine effectively, promoting not only personal satisfaction but also contributing to the broader trend of food sustainability and preservation in a competitive market.

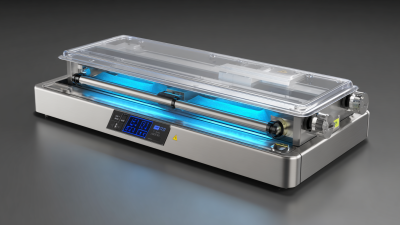

Can sealer machines are essential tools for anyone looking to preserve food and beverages effectively. By sealing your cans properly, you can increase shelf life, maintain freshness, and prevent contamination. Understanding the basic components and functions of a can sealer machine is crucial for beginners. Most machines consist of a sealing mechanism, a can holder, and an operational control panel, making them user-friendly and accessible for novice users.

When using a can sealer machine, it’s important to keep a few tips in mind. First, always ensure that the cans you use are clean and free from any residue; this will help achieve a perfect seal every time. Secondly, familiarize yourself with the settings of your machine. Different types of cans and lid materials may require adjustments to temperature and pressure for optimal sealing. Taking the time to read the manufacturer’s instructions will save you frustration down the line.

Lastly, regularly maintain your can sealer machine by cleaning and inspecting its parts. This not only prolongs the life of the machine but also ensures consistent sealing performance. By mastering these basics, you can efficiently use your can sealer machine and enjoy all the benefits of home canning.

When choosing a can sealer machine, there are several essential features to consider that can significantly enhance your canning experience. First and foremost, look for a machine that offers consistent sealing pressure. This ensures that every can is sealed properly, preventing spoilage and extending the shelf life of your goods. Additionally, ease of use is a crucial factor; machines with intuitive controls and clear instructions will make the learning curve much smoother for beginners.

Another important aspect is the versatility of the can sealer. Machines that cater to various can sizes and materials will provide greater flexibility for different canning projects. Furthermore, consider models that include a built-in vacuum function, as this can greatly improve food preservation by removing air from the cans before sealing. Advanced features, such as programmable settings for different types of food, can add even more convenience, making the entire process more efficient and enjoyable. Look for technology that simplifies your canning tasks while delivering reliable results each time.

| Feature | Description | Importance |

|---|---|---|

| Durability | Manufactured from high-quality materials that withstand regular use. | Ensures longevity and reduces replacement costs. |

| Ease of Use | User-friendly controls and setup for beginners. | Allows quick learning and minimizes setup time. |

| Seal Quality | Produces airtight seals to preserve contents effectively. | Critical for maintaining freshness and preventing spoilage. |

| Portability | Lightweight and compact design for easy transportation. | Ideal for home use and events. |

| Versatility | Compatible with various can sizes and materials. | Enhances utility for different canning projects. |

| Safety Features | Includes safeguards like automatic shut-off and protective casing. | Ensures user safety during operation. |

When it comes to operating a can sealer machine efficiently, understanding the fundamental steps is crucial for beginners. A recent industry report from the Packaged Facts suggests that the food canning market has seen an increase of 8% annually, driven by the rising demand for shelf-stable products. This highlights the importance of mastering your can sealer, as a streamlined operation can significantly impact your production volume and quality.

To start, ensure that your can sealer is set up correctly, with all parts securely installed and functioning smoothly. Always refer to the manufacturer's guidelines for maintenance schedules, as regular upkeep can enhance the machine’s lifespan. Tips like running a test seal with a few empty cans can help identify any issues early on and prevent potential production losses.

Moreover, developing a systematic approach to your sealing process can greatly improve efficiency. For instance, train your staff to follow consistent handling processes, which can reduce the chances of mishaps. Statistics indicate that improving operational efficiencies by just 10% can lead to substantial cost savings over time, making it imperative to focus on your can sealing techniques right from the start.

This bar chart illustrates the time spent on each step of the can sealing process, highlighting areas for potential efficiency improvements.

When it comes to using a can sealer machine, beginners often encounter several common pitfalls that can affect the quality of their sealed cans. One frequent mistake is failing to properly clean and prepare the lids and can rims before sealing. Any debris or residue can hinder the sealing process, leading to leaks and spoilage. Ensuring that both the can and lid are free of contaminants is crucial for a successful seal.

Another common error is not adjusting the machine to the correct specifications for different can sizes. Many users may assume that the same settings can be used for various can types, but this is not the case. Each can size may require different pressure or sealing times to ensure a tight seal. Additionally, rushing through the sealing process without checking the machine’s alignment can result in uneven seals. Taking the time to familiarize yourself with your specific can sealer machine and its settings will significantly improve your results and prevent frustrating mishaps.

Maintaining your can sealer machine is crucial for ensuring its longevity and optimal performance. Regular maintenance not only helps avoid costly repairs but also guarantees consistent sealing quality. To start, always clean the machine after each use. Residue from the cans or sealing compound can accumulate and hinder performance over time. Use a soft cloth and suitable cleaning agents to gently wipe down all surfaces, and don’t forget to check and clean the sealing heads, as they are critical to achieving a tight seal.

In addition to regular cleaning, lubricate moving parts as recommended by the manufacturer. This reduces friction and wear, allowing the machine to operate smoothly. Schedule inspections of the machine at periodic intervals to check for any potential issues, such as worn seals or misaligned parts. Lastly, ensure that your can sealer is stored correctly when not in use – in a dry, cool place away from direct sunlight to prevent damage. By following these maintenance tips, you can extend the life of your can sealer and ensure that it always performs at its best.