Leave Your Message

In today's competitive market, the importance of efficient food preservation cannot be overstated, particularly as consumers increasingly prioritize freshness and quality in their purchasing decisions. According to a report by the Food and Agriculture Organization, approximately one-third of food produced globally is wasted due to improper storage and handling, emphasizing the need for effective solutions like the Food Sealer Machine.

These machines have revolutionized food storage practices, extending shelf-life by up to five times compared to traditional methods. Furthermore, as the global food packaging market is projected to reach $500 billion by 2026, maximizing the investment in Food Sealer Machines through proper maintenance is crucial for both businesses and households. Regular servicing not only enhances the machine's performance but also ensures optimal sealing quality, ultimately leading to better food safety and reduced waste. Embrace excellence with food sealing technology that originates from China and serves the global community.

Regular maintenance of food sealer machines is crucial for ensuring seal integrity, which directly affects the quality and longevity of your food packaging. Understanding the factors that influence the effectiveness of heat sealing can help you maximize your investment. For instance, the temperature and pressure applied during the sealing process play a significant role. Uneven or inadequate sealing can lead to compromised packages that may allow air and moisture to enter, leading to spoilage.

Regular maintenance of food sealer machines is crucial for ensuring seal integrity, which directly affects the quality and longevity of your food packaging. Understanding the factors that influence the effectiveness of heat sealing can help you maximize your investment. For instance, the temperature and pressure applied during the sealing process play a significant role. Uneven or inadequate sealing can lead to compromised packages that may allow air and moisture to enter, leading to spoilage.

To maintain your food sealer, consider these tips: first, clean the sealing bars regularly to remove any residue that might hinder performance. Second, check and calibrate the machine’s temperature settings according to the type of packaging material used. Different materials require specific temperatures to achieve a perfect seal, so staying informed on these requirements is essential. Lastly, routinely inspect the sealing gaskets for wear and replace them as needed, ensuring consistent and reliable sealing.

Investing time in routine checks and maintenance not only enhances the lifespan of your food sealer but also guarantees that your food remains fresh and safe for consumption. By understanding and applying these maintenance tips, you can maintain optimal performance and maximize the benefits of your sealing machine.

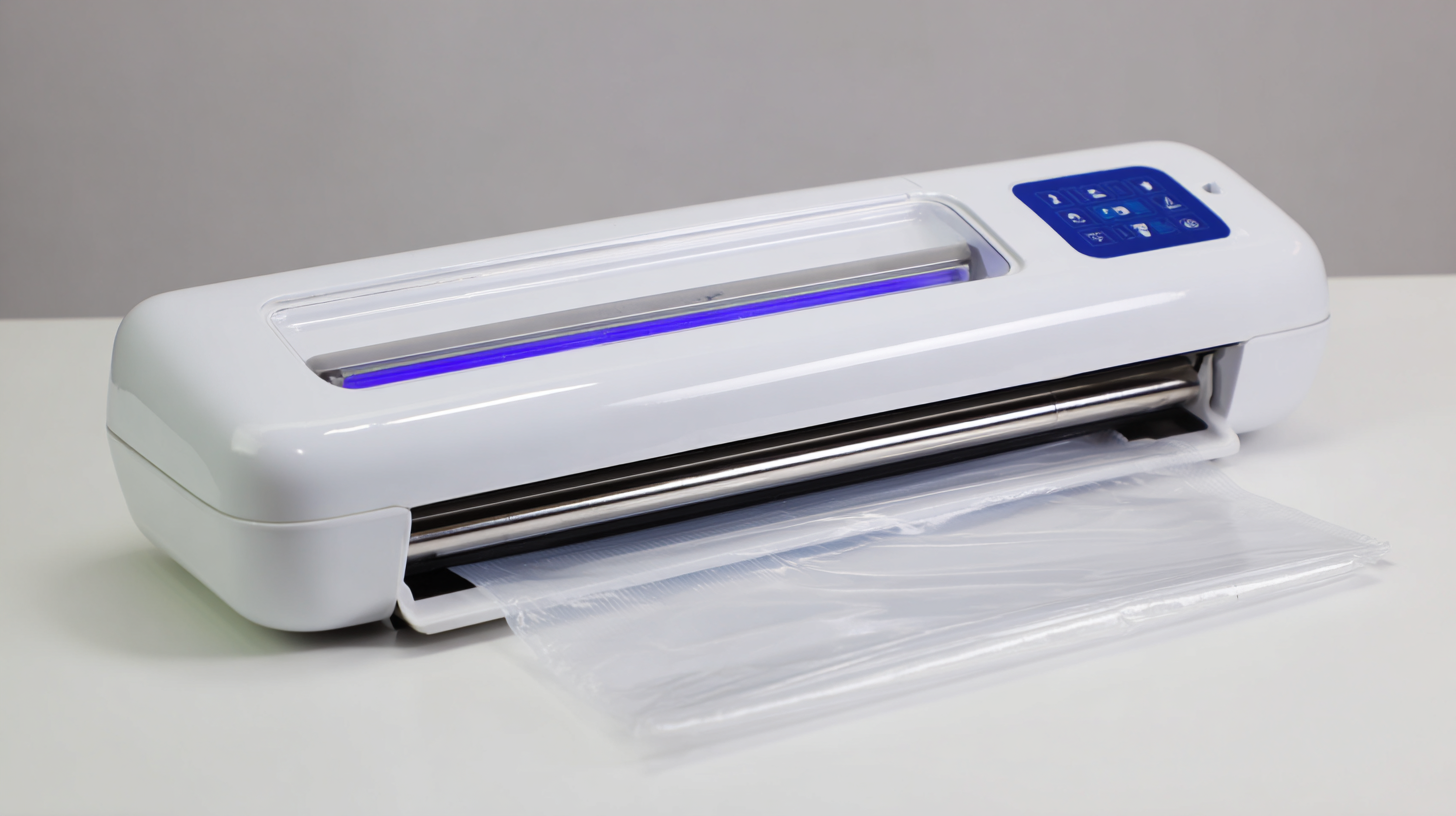

When considering a high-quality food sealer, it's essential to understand the key features that differentiate top models from their competitors. One of the most critical features is the sealing mechanism. Advanced food sealers utilize powerful suction systems that efficiently eliminate air, ensuring that bags are sealed tightly and food remains fresh for longer periods. A reliable machine should also provide adjustable sealing times and temperatures, catering to a variety of food types—from delicate items like herbs to tougher products like meats.

Another crucial aspect to consider is durability and construction quality. High-quality food sealers are often made from sturdy materials that can withstand regular use without deteriorating. Look for units with stainless steel exteriors and reinforced seals, which not only enhance longevity but also make the cleaning process easier. Additionally, features like built-in cutters and roll storage add convenience, allowing users to quickly access and prepare sealing materials without hassle. By focusing on these key features, consumers can ensure they make an informed decision when investing in a food sealer machine that meets their specific needs.

When it comes to vacuum sealers, maintenance plays a crucial role in enhancing their longevity and performance. According to a report by the Vacuum Sealer Association, regular maintenance can extend the life of a food sealer by up to 50%. This statistic underscores the importance of caring for your equipment. Basic upkeep, such as cleaning the sealing gasket and ensuring the heat element is free of debris, can significantly reduce the wear and tear on your machine.

Furthermore, maintenance practices can contribute to consistent sealing performance, which is essential for preserving food quality. The Food Preservation Institute states that vacuum sealing can extend the shelf life of food by 1 to 3 years, depending on the type of food and storage conditions. However, poorly maintained machines may result in incomplete seals, leading to spoilage and food waste. By investing a little time in the regular servicing of your vacuum sealer, you not only enhance its durability but also ensure better preservation of your investments in food products.

| Maintenance Tips | Impact on Longevity | Service Benefits | Estimated Cost Savings |

|---|---|---|---|

| Regular Cleaning | Increases lifespan by up to 30% | Improved performance and reliability | $50 per year |

| Proper Sealing Technique | Reduces wear on heating elements by 20% | Less frequent repairs needed | $30 per year |

| Avoid Overloading | Extends product life by 25% | Consistent sealing results | $40 per year |

| Use Quality Bags | Increases efficiency by 15% | Minimizes bag-related issues | $20 per year |

| Regular Maintenance Checks | Can prevent breakdowns, increasing lifespan by 40% | Peace of mind and reliability | $100 per year |

Maintaining your food sealer machine not only extends its lifespan but also delivers significant cost savings over time. According to a report by the Food Processing Research Association, scheduled maintenance can enhance the efficiency of food sealers by up to 25%, reducing energy consumption and operational costs. Regular upkeep can prevent breakdowns, which often lead to expensive repairs; in fact, the National Association of Food Equipment Distributors estimates that unmaintained machines can incur repair costs that are 50% higher than those for well-maintained equipment.

Additionally, proper maintenance ensures that food is sealed effectively, minimizing waste and spoilage. The USDA reports that vacuum sealing reduces food waste by as much as 50%, translating to substantial savings on grocery bills. By investing in maintenance, a business can see a return on investment as high as 200% through reduced food costs and improved efficiency. Overall, prioritizing food sealer maintenance is not just about the equipment; it’s a smart financial strategy that promotes sustainability and profitability.

When it comes to food preservation, investing in a high-quality food sealer machine is just the first step. To truly maximize its potential, regular professional maintenance is essential. Just like other machinery, food sealers benefit from expert attention to ensure they operate at peak performance. Professional maintenance can identify potential issues before they become major problems, enhancing the machine’s longevity and efficiency.

Furthermore, trained technicians can optimize settings and ensure that all components are aligned correctly, which directly impacts the quality of sealing and the preservation of your food.

Incorporating professional service into your maintenance routine not only safeguards your investment but also enhances its functionality. This is akin to how athletes rely on the right equipment and maintenance for peak performance. Regular professional checks can significantly reduce the risk of equipment failure, leading to less downtime and more effective food storage solutions.

By prioritizing expert maintenance, users can enjoy the full benefits of their food sealer machine, ensuring that their food remains fresh and safe for longer periods. With the food sealing technology advancing, keeping your device in top shape through professional services has never been more crucial.