Leave Your Message

In today's fast-paced business environment, optimizing the efficiency of a Label Printer Machine is crucial for maintaining a competitive edge. According to the Smithers Pira report, the global label market is projected to grow at a CAGR of 4.3% through 2024, reaching $47 billion, which underscores the importance of streamlined labeling processes. Efficient label production not only reduces operational costs but also enhances product traceability and compliance with industry regulations. Moreover, a study by the Printing Industries of America highlights that companies can increase their productivity by up to 30% through the effective use of label printing technology. As businesses strive to improve their workflow and minimize waste, understanding the best strategies to maximize the capabilities of label printer machines is essential for any organization aiming to thrive in an increasingly competitive landscape.

In today's fast-paced business environment, the implementation of advanced label printing technologies can significantly enhance operational efficiency. One of the key benefits is the ability to produce high-quality labels at a faster rate. Utilizing high-resolution printers reduces errors and ensures that labels are clear and professional, improving the overall appearance of products and packaging, which ultimately boosts brand reputation.

To optimize label printer machine efficiency, consider scheduling regular maintenance checks to prevent breakdowns that can disrupt workflow. Additionally, investing in software that integrates seamlessly with your business systems can streamline the printing process, reducing the time spent on manual input and increasing productivity.

Moreover, employing smart technology, such as batch printing and automated label generation, can drastically cut down on production time. By automating repetitive tasks, your team can focus on more strategic areas of the business, thus maximizing overall efficiency and output. Embracing these technologies not only saves time and costs but also positions your business for future growth.

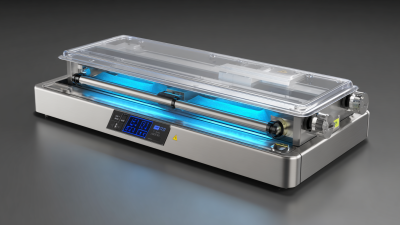

This bar chart illustrates the top strategies for enhancing label printer machine efficiency in business operations, showcasing the percentage of businesses adopting each strategy.

In today’s fast-paced business environment, the efficiency of label printer machines can significantly impact operational workflows. Key Performance Indicators (KPIs) play a crucial role in measuring this efficiency. According to a report by the National Association of Labels (NAL), optimizing label printing processes can reduce operational costs by up to 20%. Metrics such as print speed, uptime, and material waste are essential in determining how effectively a label printer contributes to overall productivity. For example, printers that maintain an uptime of over 95% are considered highly efficient, as they minimize delays in production schedules.

Additionally, measuring the quality of printed labels is another critical KPI. Industry research by the Tag and Label Manufacturers Institute (TLMI) indicates that an investment in high-quality printing can decrease rework rates by approximately 30%. This underscores the need for businesses to monitor not only speed but also the printing resolution and adherence to standards. By focusing on these KPIs, companies can identify areas for improvement, ensuring that their label printer machines operate at peak efficiency and contribute to streamlined workflows.

Routine maintenance is essential for optimizing the performance and longevity of label printer machines in any business. Just as regular maintenance has been proven to enhance the efficiency of HVAC equipment, it plays a vital role in ensuring label printers operate at their best. According to industry studies, organizations that schedule regular maintenance for their printing equipment report a significant reduction in downtime—by up to 30%—and an increase in overall productivity.

Key practices for maintaining label printers include regular cleaning and calibration, checking for wear and tear, and updating software. For instance, a maintenance schedule that includes weekly cleaning can prevent the buildup of dust and adhesive residue, which can adversely affect print quality. A report from the Print Industry Association indicates that neglecting routine maintenance can reduce printer lifespan by as much as 50%, resulting in costly replacements. By investing in consistent upkeep, businesses not only enhance printer performance but also extend the operational lifecycle of their machines, ultimately reducing costs and improving return on investment.

| Strategy | Frequency | Expected Impact | Notes |

|---|---|---|---|

| Regular Cleaning | Weekly | Improves print quality & reduces jams | Use manufacturer-approved cleaning supplies |

| Software Updates | Monthly | Enhances performance & security | Check for updates from the manufacturer |

| Optimal Settings | As Needed | Maximizes efficiency and reduces waste | Adjust based on label type and size |

| Temperature Controls | Continuous | Ensures optimal printing conditions | Keep in a controlled environment |

| Consumable Monitoring | Daily | Prevents running out of supplies during prints | Track usage to anticipate needs |

Investing in high-efficiency label printers can significantly boost productivity while delivering long-term cost savings. According to a study by Smithers Pira, the global label market is projected to reach $42.6 billion by 2024, highlighting the increasing demand for efficient labeling solutions. Businesses that upgrade to high-efficiency printers often experience a reduction in operational costs by up to 30%. This reduction is primarily due to decreased material waste and lower maintenance expenses, as these machines are designed to run more effectively and with fewer interruptions.

Incorporating advanced label printing technology can also enhance workflow, with many companies reporting up to a 50% increase in production speed. A report by Technavio noted that organizations investing in automated labeling processes can see a return on investment within two years. This efficiency not only conserves resources but allows staff to focus on more strategic tasks, driving overall business growth. By analyzing the cost-benefit ratio of high-efficiency printers, businesses can make informed decisions that support sustainability while pushing their productivity to new heights.

Integrating smart label printing solutions with inventory management systems can significantly enhance operational efficiency and reduce errors in your business. A recent report from the Association for Information and Image Management (AIIM) highlights that companies that automate their labeling processes experience a 30% reduction in time spent on inventory management tasks. By streamlining the way labels are generated and applied, businesses can ensure better accuracy and reduce the likelihood of mislabeling, which is often linked to costly operational disruptions.

Tip: Invest in a label printing solution that features real-time data integration with your inventory system. This allows for immediate updates and printing of labels as stock levels change, ensuring that your inventory reflects accurate information at all times.

Additionally, incorporating advanced features such as barcode scanning and analysis can facilitate a more seamless flow of information. According to research conducted by Zebra Technologies, organizations that adopt smart labeling technologies see an increase of up to 50% in inventory accuracy. This not only improves stock management but also enhances customer satisfaction through timely and correct order fulfillment.

Tip: Train your staff on the functionalities of your label printing system to maximize its potential. Proper training can lead to quicker adoption and better utilization of smart labeling technologies, thereby driving overall productivity in your operations.