Leave Your Message

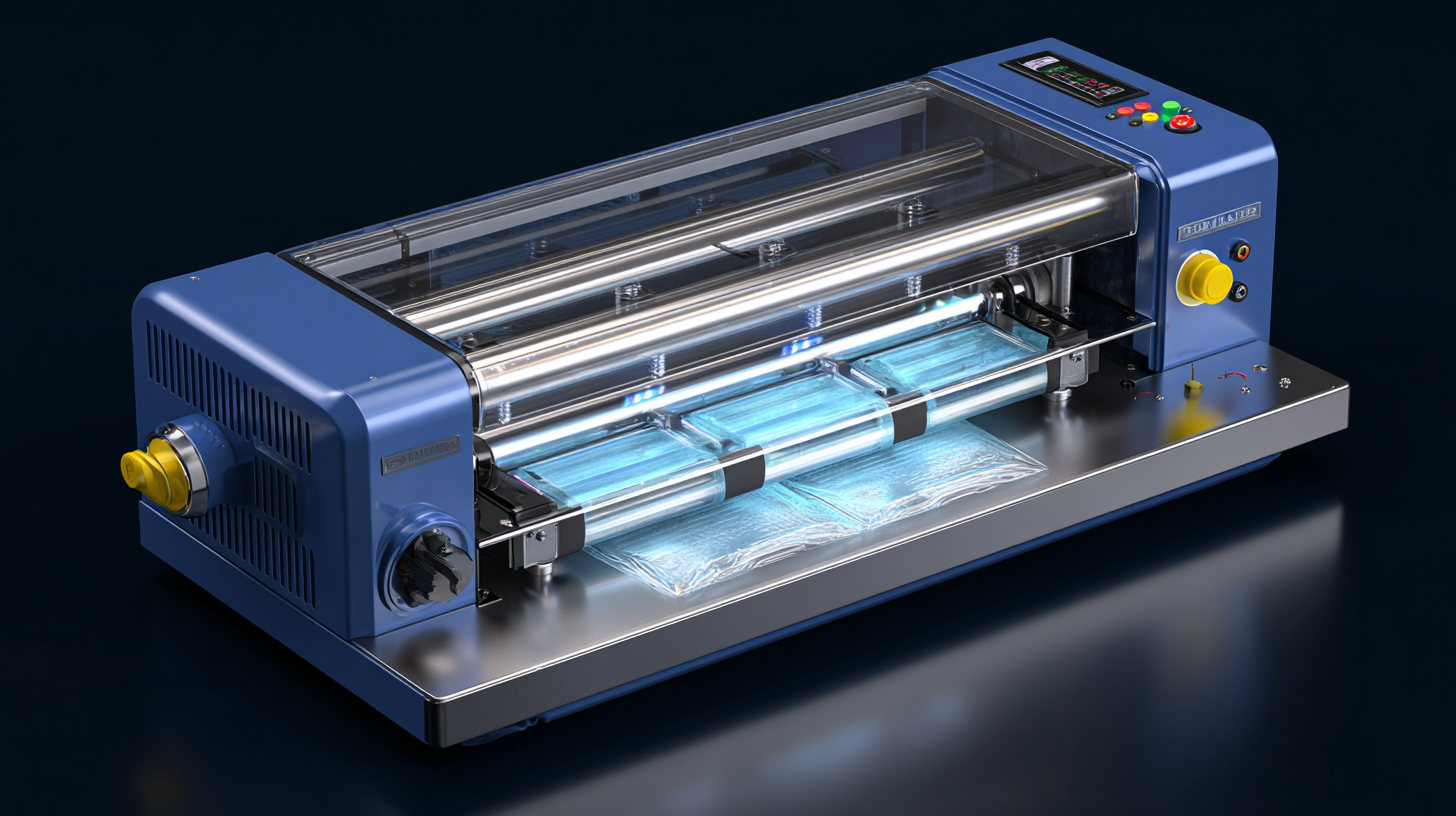

As the global demand for food preservation and packaging solutions continues to grow, the market for Vacuum Sealing Machines has seen significant advancements and innovations. According to a recent report by Grand View Research, the global vacuum sealing equipment market is projected to reach USD 4.31 billion by 2025, showcasing a robust CAGR during the forecast period. This rapid expansion is driven by the increasing consumer interest in food safety, waste reduction, and efficient storage solutions. Precision crafted vacuum sealing machines from China are at the forefront of this trend, offering advanced features and reliability that cater to the needs of global buyers. As more businesses and households recognize the benefits of vacuum sealing—from extending the shelf life of perishable goods to reducing freezer burn—the demand for high-quality, cost-effective solutions has never been higher. This blog explores how these cutting-edge machines are shaping the future of food preservation and packaging technologies.

As we approach 2025, precision vacuum sealing technology is evolving rapidly, driven by innovations in automation, sustainability, and user-centric design. Global manufacturers are increasingly adopting advanced materials and smart sensors to enhance sealing precision and reliability. These improvements not only increase shelf life for food products but also cater to a broader range of applications in sectors such as pharmaceuticals and electronics. Buyers around the world are looking for solutions that offer not just performance but also energy efficiency, allowing them to reduce operational costs while minimizing their environmental footprint.

Another significant trend is the integration of IoT capabilities into vacuum sealing machines. This connectivity offers real-time monitoring and data analytics, enabling users to optimize their sealing processes remotely. For manufacturers in China, this presents a unique opportunity to deliver cutting-edge machines that align with global demands for smarter, more efficient production methods. As customizability becomes a key factor for global buyers, companies that can provide tailored solutions will stand out in the competitive landscape. With these advancements, the vacuum sealing industry is set for significant growth, opening new avenues for collaboration and innovation in the international marketplace.

When considering vacuum sealing machines from China, it is essential to focus on the key features that can enhance both functionality and user experience. First and foremost, sealing efficiency is crucial. Look for machines that offer adjustable vacuum pressure settings to accommodate various food types, ensuring optimal preservation without crushing delicate items. Moreover, reliable sealing technology prevents air leakage, significantly extending the shelf life of stored food.

Another important feature is versatility. A top-notch vacuum sealer should not only handle food but also cater to sous vide cooking and other applications like marinating or sous vide cooking. Additional functionalities such as built-in cutters, roll storage, and multiple sealing modes add to the convenience and adaptability of the machine. Lastly, ease of use and maintenance should not be overlooked; intuitive controls and easy-to-clean components can greatly enhance user satisfaction. By prioritizing these features, global buyers can make informed decisions in selecting the right vacuum sealing machine for their needs.

In the competitive landscape of vacuum sealing machines, the global market is increasingly dominated by precision-engineered products from China. According to a recent market report by Technavio, the global vacuum sealing machine market is anticipated to grow by USD 1 billion from 2023 to 2027, fueled by rising demand for food preservation and packaging solutions. Chinese manufacturers have leveraged advanced technology and economies of scale to produce high-quality vacuum sealers that cater to both commercial and residential needs.

A comparative analysis of leading vacuum sealers reveals distinct advantages offered by Chinese brands. For instance, a study by Market Research Future highlights that models like the Anova Precision Cooker and FoodSaver V4840 outperform competitors in terms of sealing efficiency and customer satisfaction, largely due to their robust designs and user-friendly features. Additionally, a report by IBISWorld indicates that Chinese manufacturers are increasingly focusing on environmentally sustainable materials, which aligns with global trends toward eco-consciousness. This strategy not only enhances product appeal but also helps in reducing carbon footprints associated with packaging, making them a preferred choice for conscious consumers worldwide.

The evolution of vacuum sealing technology has significantly benefited from China's manufacturing prowess, impacting international standards in this industry. As Chinese manufacturers prioritize precision and quality, their vacuum sealing machines have not only met but often exceeded global benchmarks. The rigorous testing and adherence to international quality standards have led to improved functionality, reliability, and user-friendliness, making these machines vital for both home and commercial use.

Moreover, the influence of Chinese manufacturing is evident in the innovation driven by intense competition in the market. Companies continuously develop new features such as advanced sealing mechanisms, durability enhancements, and energy efficiency. This commitment to innovation pushes global manufacturers to elevate their standards, ensuring a higher quality product for consumers worldwide. Consequently, China's role in shaping vacuum sealing equipment is pivotal, as it sets a new precedent for quality and performance in this essential kitchen technology.

| Model | Sealing Width (mm) | Vacuum Level (mbar) | Power Consumption (W) | Material | Weight (kg) |

|---|---|---|---|---|---|

| Model A | 300 | 30 | 200 | Plastic | 2.5 |

| Model B | 400 | 25 | 250 | Stainless Steel | 3 |

| Model C | 250 | 20 | 150 | Aluminum | 2 |

| Model D | 350 | 28 | 220 | Plastic | 2.8 |

The vacuum sealing industry is on the cusp of transformation, driven by innovations that promise to enhance efficiency and longevity. As we approach 2025, trends such as smart technology integration and sustainability are set to redefine how vacuum sealing machines operate. Manufacturers are increasingly incorporating IoT capabilities, allowing users to monitor and control their sealing processes remotely. This not only boosts productivity but also ensures more precise sealing, resulting in reduced food waste and improved preservation.

Tips: When selecting a vacuum sealing machine, consider models with smart features that sync with mobile apps. These can provide real-time updates and troubleshooting, making the sealing process more streamlined.

Furthermore, sustainability is becoming a paramount concern in product development. Expect to see vacuum sealers designed with eco-friendly materials and energy-efficient functions that minimize their environmental footprint. Brands that prioritize recyclable packaging and energy-saving mechanisms will not only appeal to environmentally conscious consumers but also lead the way in responsible manufacturing practices.

Tips: Look for brands that offer eco-friendly options and check for certifications that guarantee sustainability. Investing in a machine that utilizes recyclable materials can help reduce your ecological impact while maintaining quality performance.