Leave Your Message

Choosing the right Label Printing Machine is crucial for business efficiency. A good machine can streamline your labeling process, enhance productivity, and improve overall quality. Various options exist in the market, each boasting unique features and specifications.

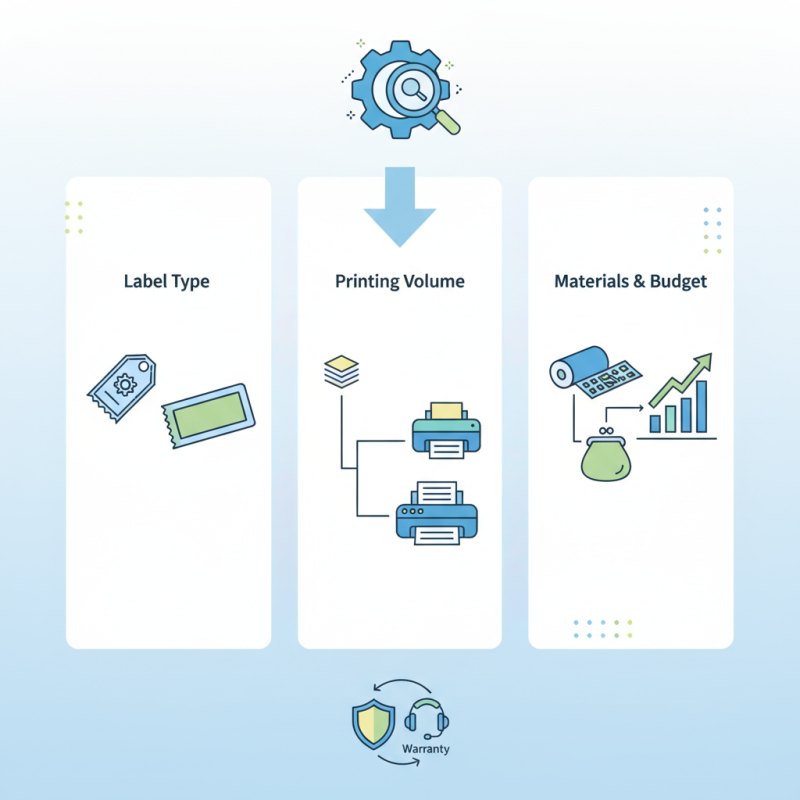

Consider the type of labels you need. Some machines excel at printing small, intricate designs, while others handle larger formats better. Assessing your printing volume is important too. A compact machine may work well for small tasks, but larger businesses may require industrial-grade models. Don’t overlook the available materials, as some machines are versatile, supporting different label types.

Reflect on your budget and long-term needs. While it may be tempting to choose the cheapest option, investing in a reliable Label Printing Machine often pays off. The initial savings may lead to higher costs down the line from repairs or inefficiencies. Remember to review the warranty and customer support services offered as well. A good experience can save you time and frustration later.

When selecting a label printing machine, several key factors come into play. Print speed is crucial. Research indicates that faster machines can produce labels at rates exceeding 200 mm per second. This can significantly boost productivity in businesses where time is essential.

The technology used is another important aspect. Thermal transfer and direct thermal technologies each have distinct advantages. A report by Smithers Pira notes that thermal transfer printing offers higher durability, making it ideal for long-lasting labels. Yet, some may find these machines more complex to operate.

Consider the volume of labels needed. High-volume operations typically require machines with higher capacity. Conversely, smaller businesses might benefit from more compact models. It’s worth noting that some users have reported issues with calibration. This can lead to inconsistencies in label quality. A thorough understanding of your needs can help avoid such pitfalls.

Choosing the right label printing machine requires understanding various printing technologies available. The main types include thermal, inkjet, and laser printing. Each has unique advantages and limitations. According to recent industry reports, thermal printers dominate the market for their speed and efficiency. They are ideal for high-volume label production, especially in retail and logistics.

Inkjet printers offer superior color quality, making them suitable for labels that require vibrant graphics. However, they often come with higher running costs. A 2023 study indicates that inkjet technology saw a 15% growth, suggesting increasing preference among businesses needing high-resolution imagery. Laser printers provide precision and durability, but can be less versatile for varied label materials.

When selecting a printing machine, consider these tips: Assess your printing volume and frequency. Higher volumes may favor thermal printers due to operational efficiency. Don't ignore maintenance costs; an affordable machine could have high upkeep expenses. Evaluate the media compatibility; some printers excel with specific materials.

Pricing can be misleading. A cheap printer may lack the durability necessary for long-term use. Lastly, read user reviews and case studies. Real-world insights reveal how machines perform in daily tasks. Observing these factors can lead you to the best choice for your labeling needs.

When choosing a label printing machine, assessing your printing volume and workflow needs is crucial. According to industry reports, 70% of businesses have underestimated their print requirements. This often leads to inefficiencies and increased costs. Understanding your average print quantity helps you select a machine that can handle your demands without excess waste.

Evaluate your daily printing needs. If your volume exceeds 1,000 labels per day, a robust model is essential. Machines designed for higher outputs typically offer better speed and durability. Conversely, smaller operations may benefit from entry-level machines. A miscalculation here could result in frequent downtimes or inadequate print quality.

Consider the nature of your workflow. Are you working in bursts or steadily? Workflows that require flexibility benefit from machines with quick setup changes. Reports indicate that 30% of businesses experience delays due to machine incompatibility. The right choice enhances productivity but requires thoughtful consideration of your specific needs. Balancing volume with workflow allows for a streamlined operation.

| Printing Volume | Daily Workflow | Label Sizes | Print Resolution | Features |

|---|---|---|---|---|

| Low (50-100 labels/day) | Occasional use | 2" x 4", 3" x 5" | 300 dpi | Standard color printing |

| Medium (100-500 labels/day) | Regular use | 4" x 6", 5" x 8" | 600 dpi | Wireless connectivity |

| High (500+ labels/day) | Continuous operation | Custom sizes | 1200 dpi | Multi-color capabilities |

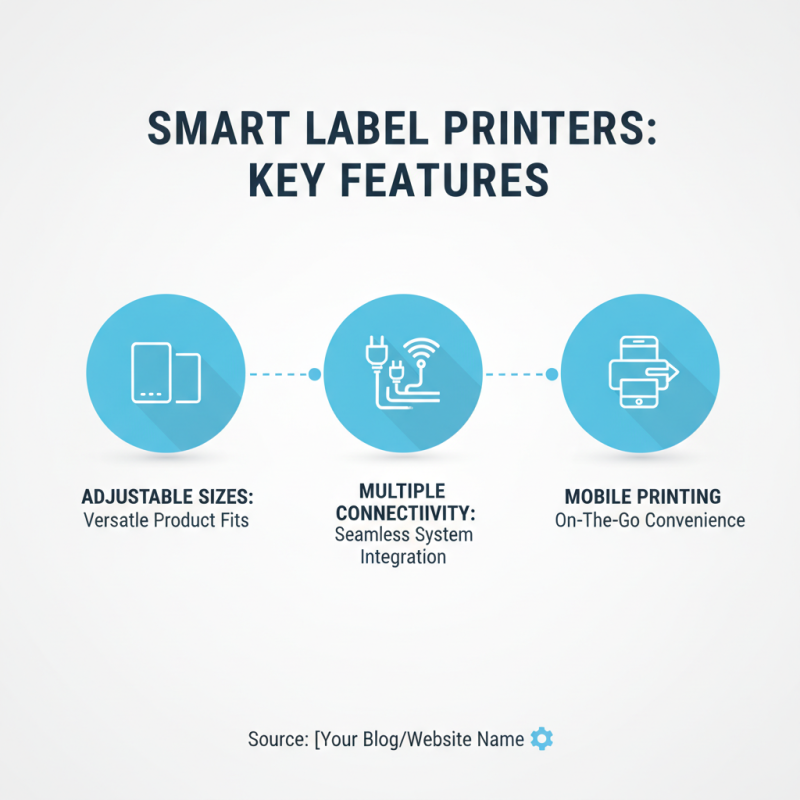

When selecting a label printing machine, additional features and customization options are key considerations. Look for machines that allow you to adjust label sizes easily. This flexibility lets you create labels that fit various products. Advanced machines often have multiple connectivity options, making it simpler to integrate them into existing systems. Some may even support mobile printing, which is a valuable feature for on-the-go labeling.

Customization is another crucial aspect. Consider machines that offer various templates and design tools. Having the option to create unique labels can set your products apart. It is worth thinking about whether the machine can handle different materials. Some projects may require waterproof or tear-resistant labels. This versatility can be beneficial.

However, it’s important to reflect on the learning curve. Some machines may require time to master their features fully. This could delay your project timeline. Evaluating your needs carefully can help avoid unexpected challenges later. Researching user reviews and experiences can provide insight into the usability of different models. Keep these points in mind as you make your selection.

When considering purchasing a label printing machine, effective budgeting is essential. Industry reports indicate that businesses can spend between $2,000 to $10,000 for a reliable machine. However, hidden costs often arise. Maintenance and materials, like labels and ink, can significantly impact your overall budget.

The cost of materials varies widely. For instance, high-quality labels can run up to $400 for a single roll. Many businesses overlook these additional expenses, leading to overruns. A survey highlighted that nearly 40% of businesses exceed their initial budget due to unforeseen costs in production.

Evaluating your needs is crucial. A machine that's too powerful for your demands may lead to wasted resources. A smaller, more efficient printer might suffice. Many users report regret over choosing excessive features. Reflecting on your specific requirements can prevent costly mistakes, leading to better financial decisions in the long run.