Leave Your Message

Packaging machines play a crucial role in modern manufacturing. They streamline processes and ensure products reach consumers efficiently. Choosing the right packaging machine is essential for various industries. Different machines cater to specific needs, making it vital to evaluate options carefully.

Consider factors like speed, accuracy, and versatility. Some machines specialize in bottling, while others excel at sealing or labeling. Understanding these distinctions can enhance operational efficiency. Reflection is needed when selecting a machine that truly meets your business demands.

While innovation drives the packaging industry, it’s important to acknowledge limitations. Not every machine fits every product. Some packaging machines struggle with complex designs or large volumes. A thoughtful approach can help manufacturers find solutions tailored to their unique challenges.

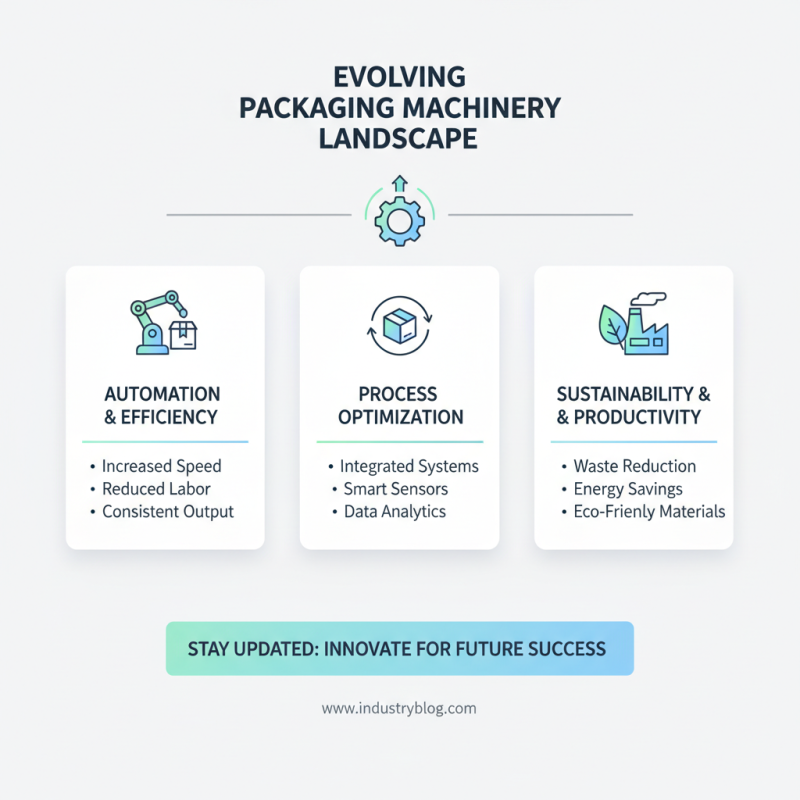

The landscape of packaging machines is rapidly evolving. Industry standards are increasingly leaning towards automation and efficiency. Companies seek machines that not only pack products but also optimize the entire process. It’s essential to stay updated on innovations that can enhance productivity while reducing waste.

Not all machines are created equal. Some may lack the adaptability to various products. For instance, a machine that excels at packing liquids may struggle with solids. This inconsistency can lead to costly errors. Companies must evaluate machines based on their specific needs. Consideration of future growth is vital. Machines should accommodate scalable production lines.

Moreover, sustainability has become a key focus. Packaging machines that help minimize material use are gaining traction. However, some technologies may require time to implement and adjust. The transition can be challenging, even if the outcome is beneficial. Industry professionals often find themselves rethinking logistics and training staff. Petty issues can arise during this transition. Embracing change is a continuous process.

When considering packaging machines, it is crucial to understand the various types available. Each type serves different applications and industries. For instance, vertical form-fill-seal machines are popular for granulated products. They efficiently pack items like rice or sugar. On the other hand, horizontal flow wrappers are great for sealing individual snacks. These machines enhance shelf appeal through attractive packaging.

Another option is shrink wrappers. They protect items by using heat to shrink the film tightly around the product. This type increases durability but may require more space. In contrast, labelers focus on branding. They ensure that each product has a clear label attached, allowing for easy identification. The choice of machine influences not only production speed but also product presentation.

However, not every machine fits every business. The initial cost can be daunting. Maintenance may also pose challenges. It's essential to evaluate long-term efficiency over short-term savings. Some machines require special training for operators. This can add to the overall expenses. Creating a balance between cost and functionality can be a daunting task. Understanding these details makes the decision process more informed.

| Machine Type | Application | Speed (Packages/min) | Cost ($) | Efficiency (%) |

|---|---|---|---|---|

| Vertical Form Fill Seal | Snacks, Powdered Products | 60 | 25,000 | 85 |

| Horizontal Flow Wrapper | Bakery Items, Confectionery | 80 | 30,000 | 90 |

| Labeling Machine | Bottles, Cans | 120 | 20,000 | 95 |

| Cartoning Machine | Products into Boxes | 50 | 40,000 | 88 |

| Filling Machine | Liquids, Granulates | 100 | 35,000 | 92 |

| Shrink Wrapper | Bundles, Multipacks | 70 | 28,000 | 85 |

| Stand Up Pouch Machine | Snacks, Pet Food | 60 | 27,000 | 89 |

| Overwrapping Machine | Cigarettes, Gifts | 50 | 45,000 | 84 |

| Wrap Around Case Packer | Bottles, Cans | 85 | 50,000 | 91 |

| Automatic Tray Sealer | Meat, Vegetables | 40 | 32,000 | 86 |

When evaluating packaging machines, speed,

efficiency, and versatility are essential metrics.

Recent studies indicate that packaging line speeds can reach up to 150 units per minute.

However, many operations still experience bottlenecks due to outdated machinery.

In fact, nearly 30% of production facilities face efficiency drops because of slow equipment.

This statistic highlights the need for modern solutions to achieve optimal throughput.

Efficiency, measured in terms of output per hour, often varies significantly across machines.

Some new models can increase overall efficiency by up to 25%.

This improvement is crucial, especially for companies handling large volumes.

However, choosing the right machine isn’t just about speed.

Versatility plays a critical role too.

Machines capable of handling multiple package types can save time and reduce waste.

Reports suggest that versatile packaging machines can cut product changeover times by nearly 50%.

Despite these advancements, not all machines live up to the claims.

Companies find that their machines may not deliver as promised, leading to frustration.

It's vital for businesses to conduct thorough evaluations before committing to any device.

The blend of speed, efficiency, and versatility must align with specific production requirements.

This alignment is not always easy, but it’s essential for leveraging full potential in the packaging process.

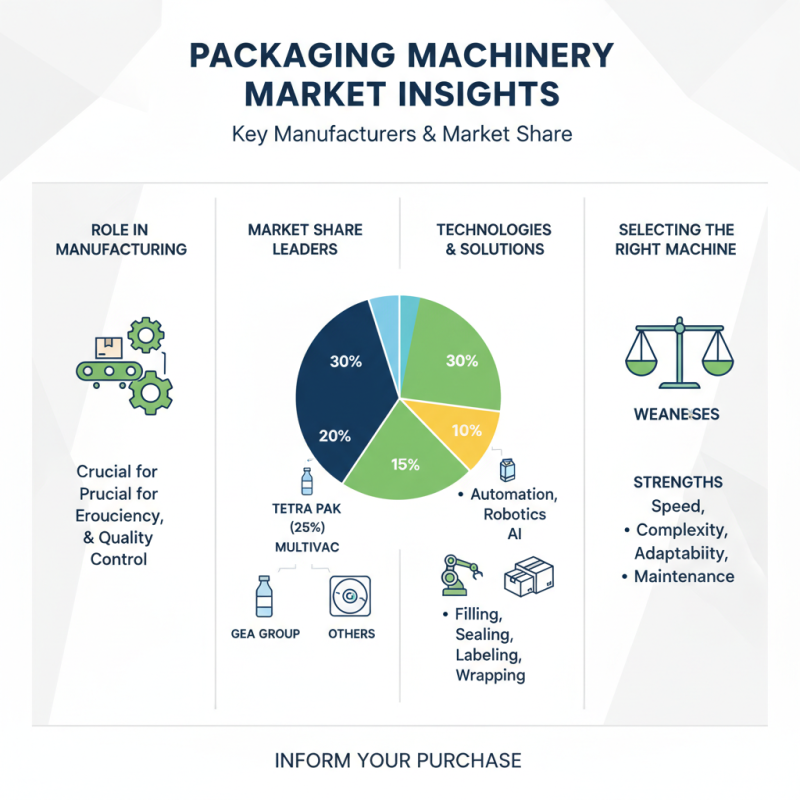

Packaging machinery plays a crucial role in manufacturing. Understanding market share insights helps businesses select the right machines. Several key manufacturers dominate the market. They offer different technologies and solutions. Each manufacturer has its strengths and weaknesses. Knowing these can guide your purchasing decisions.

Tips: Evaluate your production needs carefully. Not every machine fits all operations. Test different models before committing.

Innovation drives the packaging machinery sector. Automation and smart technologies improve efficiency. However, some machines may overwhelm operators. Too much complexity can lead to mistakes. Continuous training is essential for staff. Consider user-friendly designs to ease the learning curve.

Tips: Keep an eye on market trends. This helps in making informed choices. Don’t rush into buying. Incremental upgrades can be more effective.

As packaging technology continues to evolve, sustainability emerges as a key focus. Reports indicate that 74% of consumers prefer eco-friendly packaging. This is driving companies toward using materials that reduce environmental impact. Biodegradable options and recycled materials are in high demand.

Automation also plays a vital role in this landscape. Industry studies reveal that automated packaging can increase efficiency by 30% while reducing labor costs. However, the integration of advanced robotics presents challenges. Many businesses struggle with initial investments and training staff. These hurdles highlight the need for a balanced approach.

Despite innovations, some issues persist. Not all sustainable materials provide the durability that traditional packaging does. Companies need to evaluate the trade-offs closely. Balancing cost, efficiency, and environmental responsibility remains a complex puzzle. The future of packaging technology will depend on overcoming these limitations while meeting consumer expectations.