Leave Your Message

In the ever-evolving landscape of beverage innovations, the Boba Sealing Machine has emerged as a vital tool for bubble tea enthusiasts and business owners alike. As we dive into the top five Boba sealing machines of 2023, it is essential to understand the significance of this equipment in ensuring the integrity and quality of each drink. According to industry expert Dr. Lisa Chang, a renowned specialist in beverage technology, “A perfectly sealed drink not only enhances customer experience but also plays a crucial role in preserving the freshness and flavor of the ingredients.”

The demand for bubble tea continues to soar, making it imperative for shops to invest in reliable sealing solutions. A high-quality Boba Sealing Machine can minimize spillage, enhance portability, and elevate the aesthetic appeal of the drinks. In today’s competitive market, shops with efficient sealing processes are likely to gain an edge, attracting more customers while improving operational efficiency. Join us as we explore the leading Boba sealing machines that promise to deliver perfectly sealed drinks, ensuring that each sip is as delightful as intended.

Boba sealing machines are pivotal in ensuring the quality and presentation of bubble tea, a beverage characterized by its chewy tapioca pearls and vibrant flavors. These machines create an airtight seal on the cups, preserving the freshness of the drink and preventing spills, which is essential for enhancing the customer experience. According to industry reports, over 90% of boba customers prefer tightly sealed drinks, emphasizing the importance of reliable sealing methods in maintaining beverage integrity during transportation and consumption.

In the competitive bubble tea market, the significance of effective sealing cannot be overstated. A poorly sealed cup can lead to leaks, compromising the quality of the drink and resulting in potential waste. Furthermore, an efficient sealing process can increase service speed, a critical factor in high-demand environments. Data suggests that businesses utilizing advanced sealing technology can witness up to a 30% boost in operational efficiency, allowing them to serve more customers faster without sacrificing drink quality.

Tips for choosing the right boba sealing machine include considering the machine's speed and sealing quality. It's also advisable to assess the warranty and maintenance support offered by the manufacturer to ensure long-term reliability. Additionally, integrating training for staff on the proper use of sealing machines can significantly reduce human error, ensuring that every drink is sealed securely and maintaining customer satisfaction.

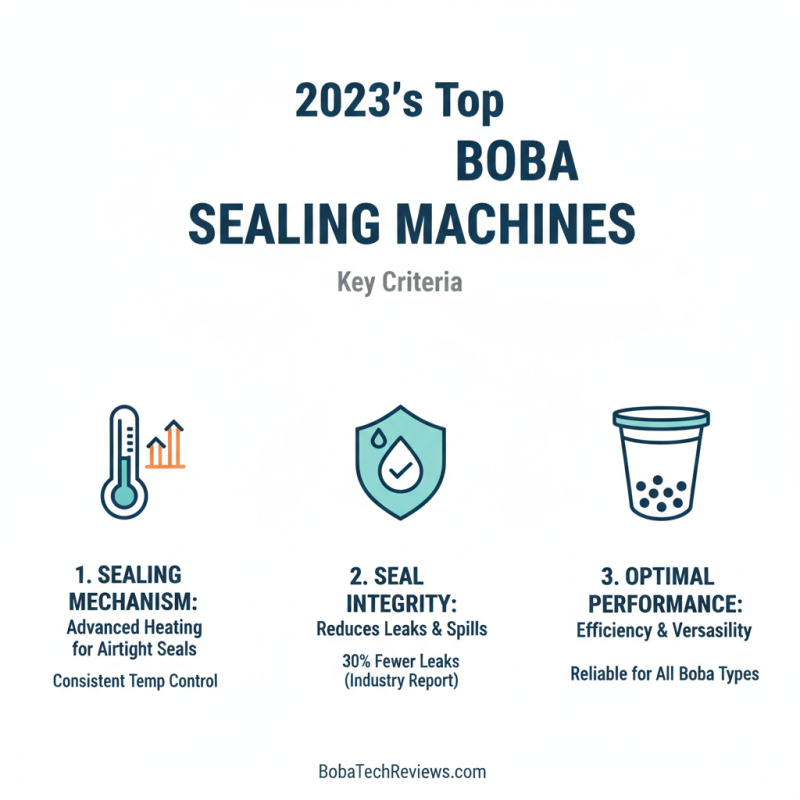

When selecting the best boba sealing machines for 2023, it’s crucial to consider several key criteria to ensure optimal performance and versatility. First, the sealing mechanism plays a vital role in the efficiency of sealing drinks. Machines with advanced heating technology provide consistent temperature control, which is essential for achieving airtight seals. Industry reports indicate that machines equipped with high-quality heating elements can enhance seal integrity by up to 30%, reducing the risk of leaks and spills during transportation.

Another important factor is the machine’s capacity and speed. High-demand establishments require machines that not only seal drinks quickly but also accommodate various cup sizes and materials. Data from recent market analyses suggest that machines designed for high volume can increase productivity by over 40%, making them ideal for bustling environments like bubble tea shops and cafes. Additionally, user-friendly features such as digital displays and automatic functions simplify operation and minimize the learning curve for new staff.

Tips: When investing in a sealing machine, always look for models that offer adjustable sealing settings. This versatility can help adapt to different cup types and ensure a perfect seal every time. Another tip is to prioritize machines with easy maintenance features, as this can significantly reduce downtime and keep your establishment running smoothly.

In the rapidly growing bubble tea industry, the importance of sealing machines cannot be overstated. According to a recent market report, the bubble tea market is projected to reach a staggering $3.2 billion by 2025, with a compound annual growth rate (CAGR) of 7.5%. This surge highlights the need for efficient beverage sealing solutions that ensure freshness and reduce spillage. Boba sealing machines play a critical role in maintaining the integrity of each drink, enhancing the overall customer experience.

When selecting a boba sealing machine, several key features contribute to its effectiveness. First, temperature control is essential for achieving a perfect seal, with optimal heat settings ensuring that the plastic film adheres properly to the cup. Additionally, user-friendly interfaces and quick heating times can significantly improve workflow efficiency in busy shops. According to industry experts, machines that can seal multiple cup sizes and types tend to perform better in diverse settings, allowing businesses to cater to a broader range of products and customer preferences.

Moreover, the benefits of investing in a high-quality sealing machine extend beyond just functionality. Reports indicate that businesses utilizing advanced sealing technology often see a reduction in drink wastage, leading to more cost-effective operations. Enhanced aesthetics, with clean, reliable seals, also attract more customers, as well-sealed drinks convey professionalism and attention to detail. Thus, understanding the features and advantages of contemporary boba sealing machines is crucial for any bubble tea business aspiring to thrive in this competitive market.

| Rank | Model | Sealing Speed (cups/min) | Temperature Control | Weight (lbs) | Price (USD) |

|---|---|---|---|---|---|

| 1 | Model A | 25 | Yes | 15 | 300 |

| 2 | Model B | 20 | No | 12 | 250 |

| 3 | Model C | 30 | Yes | 14 | 280 |

| 4 | Model D | 15 | No | 10 | 200 |

| 5 | Model E | 22 | Yes | 13 | 260 |

When it comes to sealing drinks, the quality of your boba sealing machine can significantly impact both presentation and customer satisfaction. In 2023, the market features a variety of models that not only promise efficiency in sealing but also come at different price points. Evaluating these machines requires careful consideration of their performance metrics such as sealing speed, durability, and ease of use. Generally, higher-priced models offer advanced features like adjustable sealing temperatures and automated processes, which can enhance productivity in a busy environment.

When choosing a sealing machine, remember that price doesn’t always equate to quality. Some mid-range options provide surprisingly robust performance, ensuring a tight seal without breaking the bank. It’s essential to compare the specifications and user reviews of each model, as this will help you identify the best value for your specific needs.

**Tips:** Always test a machine with different cup sizes and materials to see how well it adapts to various requirements. Additionally, consider the maintenance cost over time, as some machines may require more frequent repairs or replacement parts, increasing overall expenditure. Lastly, a warranty can be a crucial factor, offering peace of mind for your investment.

When operating a boba sealing machine, proper use and maintenance are crucial for ensuring consistently high-quality drinks. According to a 2023 industry report, improper sealing can lead to significant product waste, with up to 12% of drinks being discarded due to leakage or poorly sealed lids. To prevent this, it's essential to follow the manufacturer's guidelines on adjusting machine settings according to the type of cups and seals being used. Ensuring the sealing surface is clean and free from residues will contribute to tighter seals, enhancing both the presentation and the drink's overall integrity.

Regular maintenance is another critical aspect of extending the lifespan of your boba sealing machine. Cleaning the sealing area after every use can prevent buildup that might affect performance. Industry experts recommend a thorough inspection every month, including checking the heating element and the sealing pads for wear and tear. According to market analysis, establishments that adhere to strict maintenance protocols can reduce operational costs associated with machine failures by nearly 25%. By investing the time in both proper usage and maintenance, businesses can maximize their efficiency and enhance customer satisfaction with perfectly sealed boba drinks.