Leave Your Message

In the vibrant world of boba tea, ensuring the perfect drink closure is as crucial as crafting the ideal beverage itself. According to Dr. Emily Chen, a renowned expert in the boba tea industry, "The right Boba Tea Sealing Machine not only preserves the drink's freshness but also enhances the customer experience." As the demand for boba tea continues to soar, so does the importance of using advanced sealing technology to maintain the quality and flavor of these delightful concoctions.

Selecting the best Boba Tea Sealing Machine is essential for any business aiming to provide exceptional service. These machines not only prevent spills and leaks but also contribute to the overall aesthetic appeal of the drink, enticing customers with a beautifully sealed cup. In our exploration of the top five sealing machines, we will delve into their features, performance, and the impact they can have on your boba tea operation. Ultimately, investing in a reliable sealing machine can transform how your beverages are presented and enjoyed, ensuring that every sip of boba tea is a delightful experience.

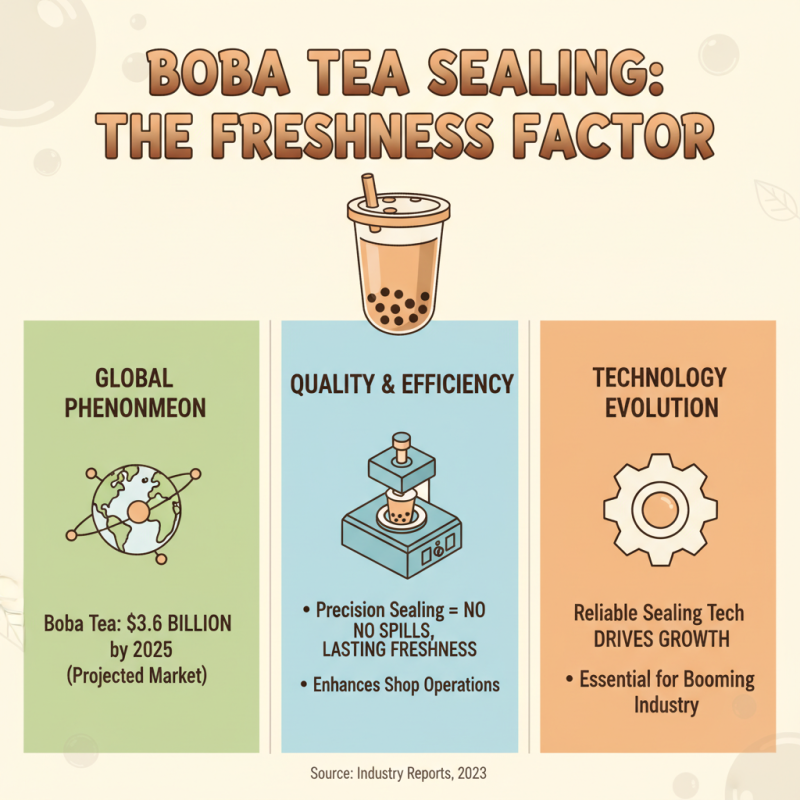

Boba tea, also known as bubble tea, has taken the beverage industry by storm, with its popularity surging globally. An essential component in ensuring an enjoyable boba experience is the sealing of cups, which preserves the drink's freshness and prevents spills. Boba tea sealing machines have evolved to meet this demand, offering precision and efficiency that enhance operational efficiency for shops. The global boba tea market is expected to reach approximately $3.6 billion by 2025, which underscores the necessity for reliable sealing technology in this booming industry.

Modern boba tea sealing machines utilize advanced technology to provide airtight seals, minimizing leakage while maintaining the quality of the drink. A study indicates that approximately 60% of boba tea consumers prefer drinks that are sealed, as this not only keeps the beverage fresh but also enhances the overall aesthetic presentation of the drink. Furthermore, many machines have implemented features such as adjustable sealing temperatures and speeds, catering to varying cup sizes and materials. This adaptability is crucial, considering that successful boba tea shops often serve different types of beverages and packaging options to meet diverse customer preferences. As the market continues to grow, investing in high-quality sealing machines becomes a priority for establishments aiming to maintain their competitive edge.

When selecting a sealing machine for boba tea, it's essential to consider several key features that ensure optimal performance and reliability. One of the primary aspects to look for is the heating element quality. A high-quality heating mechanism guarantees even temperature distribution, which is vital for sealing various cup sizes and materials effectively. Additionally, look for machines that offer adjustable temperature settings. This flexibility allows you to tailor the sealing process per the specific requirements of different drinks.

Another crucial feature is the sealing capacity of the machine. A model that accommodates high-volume beverage production will significantly enhance your operational efficiency, especially during peak hours. Consider the speed of the sealing process as well; machines with quick sealing functions help streamline service without compromising on the quality of the drink closure. Lastly, ease of use and maintenance can greatly impact day-to-day operations. A user-friendly interface and easy cleaning mechanisms help reduce downtime and improve staff productivity, making it easier to keep up with customer demand while ensuring that each drink is perfectly sealed.

When it comes to serving the perfect boba tea, an essential component is the sealing machine. A high-quality boba tea sealing machine not only ensures that your drinks remain fresh and spill-free but also enhances the overall presentation, making them visually appealing to customers. Among the various options available in the market, certain machines stand out due to their efficiency, durability, and user-friendly features.

One of the top recommended machines is designed for high volume tea shops, offering quick sealing times and consistent results. These machines often allow for the adjustment of sealing temperature and pressure, ensuring a perfect fit for different cup sizes and materials. Additionally, they are built with robust materials, making them reliable for daily use in busy environments. For smaller establishments or home use, there are compact models available that maintain quality while being space-efficient.

When selecting a sealing machine, consider factors such as sealing speed, ease of operation, and maintenance requirements. A good sealing machine will not only streamline your service but also enhance the customer experience by providing perfectly sealed drinks every time. Investing in a quality machine can contribute significantly to the operational efficiency of your boba tea business.

When it comes to serving the perfect boba tea, the efficiency of the sealing machine plays a pivotal role. A high-quality sealing machine ensures a tight seal that prevents any leaks while preserving the freshness of the drink. In a comparative analysis, factors such as sealing speed, temperature control, and durability of materials become crucial indicators of a machine's performance. Machines that offer adjustable settings for different cup sizes and sealing methods can enhance workflow, making them ideal for busy bubble tea shops.

Tips: When selecting a sealing machine, consider the volume of orders during peak hours. A faster sealing machine can significantly reduce wait times for customers, improving overall service efficiency. Additionally, look for machines that provide consistent sealing quality. Inconsistent seals can lead to customer dissatisfaction due to potential spills and lost product.

Another important aspect is ease of maintenance. Machines that are easy to clean and service can reduce downtime, keeping operations smooth. Regular maintenance checks ensure the longevity of the machine and its sealing capabilities, which is essential for consistent product quality in your boba tea offerings.

When operating a boba tea sealing machine, proper maintenance is crucial for ensuring optimal performance and longevity. Regularly inspect the sealing film and ensure it is correctly threaded and tensioned. This practice not only guarantees a tight seal but also prevents jams that could interrupt your workflow. Additionally, keep the machine clean by wiping down surfaces daily and removing any residue that may accumulate during use, as this can affect sealing quality and hygiene.

Another essential tip for maintaining your boba tea sealing machine is to regularly check the heating element. Over time, buildup or damage to the heating plate can lead to ineffective seals or even machine malfunction. If you notice any inconsistencies in sealing, it may be time to replace the heating element. Furthermore, remember to lubricate moving parts periodically to ensure smooth operation, as this helps reduce wear and tear and maintains the machine's efficiency. By incorporating these maintenance tips into your routine, you can significantly extend the life of your sealing machine while ensuring every drink is perfectly closed.

| Machine Model | Sealing Speed | Seal Type | Weight | Price Range | Maintenance Tips |

|---|---|---|---|---|---|

| Model A | 15 cups/min | Double Sealing | 10 kg | $300 - $400 | Clean after every use; check seals monthly. |

| Model B | 12 cups/min | Single Sealing | 8 kg | $200 - $300 | Inspect heating elements weekly; lubricate moving parts. |

| Model C | 10 cups/min | Double Sealing | 12 kg | $350 - $450 | Daily cleaning; avoid overheating. |

| Model D | 18 cups/min | Single Sealing | 7 kg | $180 - $280 | Regular inspections; maintain cleanliness. |

| Model E | 14 cups/min | Double Sealing | 9 kg | $250 - $350 | Change sealing film regularly; clean rollers. |