Leave Your Message

In the fast-paced world of manufacturing, efficiency is key. Liquid Filling Machines play a crucial role in various industries, from food and beverage to pharmaceuticals. According to John Smith, a renowned expert in packaging technology, “Understanding the types of liquid filling machines can streamline production and enhance product quality.” His insight highlights the importance of recognizing the right equipment for specific needs.

Different types of Liquid Filling Machines are designed for varied applications. Each machine has unique features suited for its tasks, influencing productivity. Selecting the correct machine can be overwhelming, especially with the variety available. Mistakes in this choice can lead to production delays and increased costs.

Buying the right Liquid Filling Machine is essential. Yet, many companies overlook critical factors. An informed choice can greatly enhance operational efficiency. Understanding the landscape of filling machines allows businesses to make better decisions. This article explores the top ten types you should know. It offers guidance for anyone navigating this complex world.

Liquid filling machines play a crucial role in various industries. They streamline the packaging process for liquids, ensuring efficiency and consistency. According to a 2021 industry report by Research and Markets, the global liquid filling machine market is expected to grow at a compound annual growth rate (CAGR) of 4.8% from 2021 to 2026. This growth indicates a rising demand for automated solutions in different sectors.

The importance of liquid filling machines cannot be overstated. These machines improve productivity and reduce human error. In industries like food and beverage, pharmaceuticals, and cosmetics, accuracy is key. A study from Allied Market Research highlights that the food and beverage segment dominated the market in 2020, accounting for over 40% of total revenue. However, not all machines are perfect. Issues such as inconsistent fill volumes and maintenance requirements can arise.

Regular training and adjustment are necessary to maintain optimal performance. In a fast-paced production environment, these challenges can disrupt workflows. Industry reports emphasize the need for continual advancements and innovation in machine technology. This highlights a significant area for reflection as businesses must adapt to evolving customer needs and regulatory standards.

When it comes to liquid filling machines, understanding their mechanics is crucial. There are several types based on how they fill containers. One popular type is the gravity filler. This machine relies on gravity to fill products. It is commonly used for low-viscosity liquids like water and juices. According to industry studies, gravity fillers account for approximately 30% of the liquid filling market. Their design is simple, but it may lead to variations in fill levels.

Another widely used type is the pump filler. This machine uses a pump to move the liquid from a reservoir into the container. It suits a variety of products, from thick sauces to thin beverages. Around 25% of manufacturers prefer pump fillers due to their accuracy. However, they require regular maintenance to avoid mechanical failures. The complexity of this machine can sometimes frustrate operators.

Pressure fillers are also popular. They use air pressure to push the liquid into containers. A recent report found that pressure fillers are often chosen for carbonated beverages. This method ensures consistency in fill levels. Yet, it can be tricky to calibrate and control the pressure accurately. Every machine type has its strengths and weaknesses. Understanding these is vital for selecting the right equipment for your needs.

When it comes to liquid filling machines, gravity fillers and pressure fillers are two main types that often come into play. Gravity fillers operate by using the force of gravity to fill containers. They are simple and cost-effective, making them a popular choice for many businesses. However, they require a steady flow of liquid and may struggle with thicker products. This can lead to inconsistencies in fill levels, which is not ideal for precision applications.

On the other hand, pressure fillers utilize pressurized tanks to dispense liquid. This method allows for a more controlled flow, ensuring that fill levels remain consistent, even with thicker liquids. Pressure fillers can accommodate a variety of container shapes and sizes, increasing their versatility. However, they can be more complex and may require regular maintenance to ensure proper functioning. Both types have their advantages and challenges, and choosing the right one depends on the specific needs of the production line. It's essential to weigh these factors carefully before making a decision.

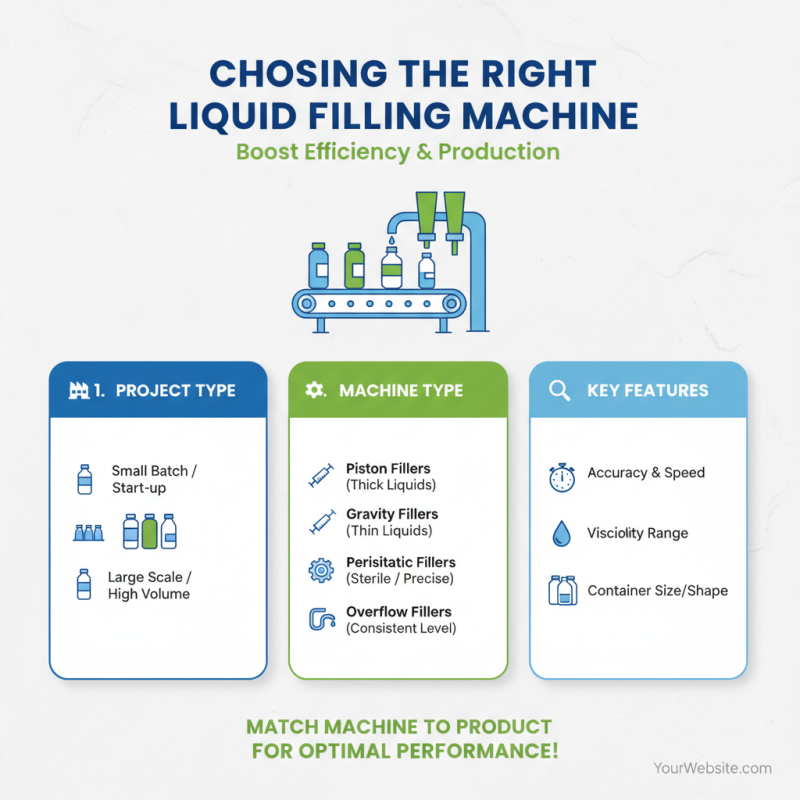

Choosing the right liquid filling machine is crucial for efficiency. Different projects require different types of machines, each with unique features. Understanding these features can help you make a sound decision.

When considering a machine, think about the fill volume. Is it small or large? Machines vary in their capability to handle different volumes. Some may struggle with small batches, while others are designed for high-speed production.

Tips: Assess your production needs carefully. Look for a machine that aligns with your capacity requirements.

Another factor is the type of liquid. Thick liquids require different mechanisms than thin ones. Some machines are versatile, but not all are suitable for every liquid type. Poor compatibility can lead to issues.

Tips: Research the specific machine's compatibility with your liquid type. Test small batches before full-scale production.

Also, consider the budget. High-tech machines can be costly. However, cheaper options may not meet quality standards. Striking a balance is essential. Invest wisely.

Tips: Don’t ignore maintenance costs. They can add up over time, impacting your long-term budget.

Liquid filling technology has seen remarkable advancements in recent years. Modern machines are designed for efficiency and precision. They cater to various industries, from food and beverage to pharmaceuticals. These innovations aim to reduce waste while improving production rates. Many machines now feature smart technology. This allows real-time monitoring and adjustments during the filling process.

Automation is a key trend shaping the future of liquid filling. Businesses are moving towards fully automated systems. These systems minimize human error and increase safety. Another interesting development is environmentally friendly materials. Many filling machines are now made from recyclable or sustainable resources. This reflects a growing commitment to sustainability in manufacturing.

However, adapting to these trends can be challenging. Not all businesses can afford the latest technology. There's also a learning curve with new systems. Training staff on advanced machinery takes time and effort. Many companies grapple with these issues. They recognize the importance of innovation but may hesitate to invest heavily. This creates a tension between keeping up with trends and budget constraints.