0102030405

2025: Automation Equipment Empowers Factories to Cut Costs and Boost Efficiency

2025-05-22

In 2025, automation equipment is injecting unprecedented impetus into the development of factories, delivering remarkable results in cost reduction and efficiency enhancement. A multitude of enterprises are actively adopting advanced automation solutions, revolutionizing their production models to gain a competitive edge in the market.

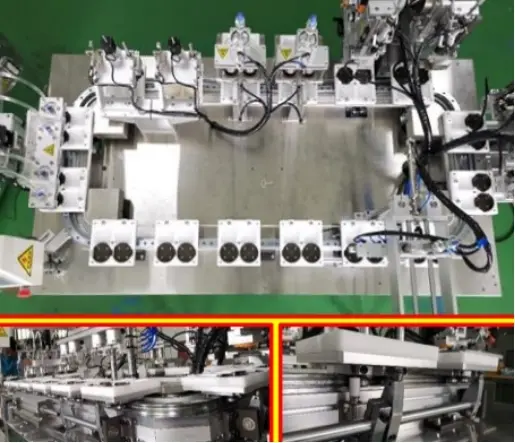

Jiangxi Jianguan Technology Co., Ltd., a leading enterprise in the auto parts industry, has made significant strides in digital transformation. Inside its production workshop, intelligent devices seamlessly integrate with automated production lines. In the past, relying on manual experience to diagnose production issues was time-consuming, labor-intensive, and often inaccurate. Now, state-of-the-art intelligent equipment can precisely locate products in real-time and adjust parameters promptly, effectively minimizing production errors. The automated operation of these devices has substantially reduced the company’s dependence on human labor, enabling the reallocation of saved labor costs to research and innovation, thereby further strengthening its market competitiveness. According to Wu Jiankang, the company's administrative manager, after the introduction of digital technologies, production costs have decreased by 10%, production efficiency has increased by approximately 15%, and product output has seen a significant surge. This allows the enterprise to plan production more accurately and optimize resource allocation, helping it stand out in the market.

Weihai Tianrun Intelligent Technology Co., Ltd. has also achieved remarkable success in automation transformation. Tianrun Industry initiated its automation journey as early as 2015. Through deep integration of automation, digitization, and intelligence, coupled with the application of cutting-edge information technologies such as 5G, big data, the Internet of Things (IoT), and artificial intelligence, the company has comprehensively elevated the automation and intelligence levels of its production lines. In its smart workshop, intelligent production robots, including gantry robots and automatic grinding units, operate efficiently, handling tasks such as random part grabbing and material grinding. The production process is centrally controlled via an industrial internet platform, with all stages—from production and processing to logistics and quality inspection—completed by industrial robots and automated logistics devices. By collecting data on equipment operation, quality inspection, and logistics, the system can automatically analyze and manage production line quality, equipment failures, and material flow. These measures have significantly improved production efficiency, product quality, and workplace safety. Cong Hongfeng, Director of the Enterprise Management and Data Management Department at Tianrun Industry Technology Co., Ltd., stated that after the intelligent transformation, the automation and digitization rate of the company's production lines reached 90%, daily production capacity increased from 120 units to 160 units, the workforce was reduced from 35 to 7 people, and overall energy consumption decreased by 37%, marking a fundamental shift in the company's management approach.

Moreover, in modern manufacturing, cleanliness and safety are crucial for ensuring production efficiency and safeguarding employees' health. Sunwoda, a global leader in the new energy industry, has established an intelligent operation network covering multiple production scenarios by introducing three products from Pudu Robotics: CC1, Happy Delivery 2, and T300. The CC1 cleaning robot addresses the demanding cleaning requirements of manufacturing workshops, warehouses, and dust-free environments. In manufacturing workshops, with its automatic detergent dispensing and powerful dual-brush technology, it achieves an oil stain removal rate of 99.7%, significantly reducing work-related accidents caused by slippery surfaces. In warehouses, its real-time vacuuming and floor-washing combination effectively controls dust from tire wear, protecting stored materials and preventing dust accumulation. In dust-free workshops, it coordinates with AGV/AMR systems in milliseconds, ensuring seamless integration between cleaning operations and material transportation. The Happy Delivery 2 robot tackles the challenges of multiple production lines and high-volume operations. A network of 32 robots executes a full closed-loop management process, covering tasks from sampling inspection and delivery to production line replenishment, material warehousing, and waste recycling. This has increased material distribution efficiency by 40%, with an average daily handling capacity exceeding 3,000 batches, driving an 18% increase in overall production capacity. Deeply integrated with the Manufacturing Execution System (MES) of the smart factory, it covers approximately 60% of material flow and distribution processes. The PUDU T300, serving as the central connector for production processes, has enhanced material turnover efficiency by 50%. Its unique narrow-passage navigation capability (with a minimum passage width of 60 cm) enables it to maneuver flexibly in confined spaces, facilitating seamless material transportation between production lines. These three robotic systems, interconnected through a unified IoT platform, form a “logistics-cleaning-distribution” trinity intelligent network, elevating factory operational efficiency to new heights.

As more and more enterprises recognize the immense advantages of automation equipment and actively invest in its adoption, the role of automation equipment in empowering factories to cut costs and boost efficiency will become even more prominent. It will continuously drive the manufacturing industry towards high-end, intelligent, and green development, reshaping the industry landscape.https://www.hrdautomaticequ.com/news/