Automation Technology Innovation of BB Cream Filling Machines Leads Industry Transformation and Facilitates the Efficient Upgrading of the Beauty Industry

With the continuous increase in the global demand for cushion BB creams in the beauty market, the technological innovation of filling equipment has become the focus of attention in the industry. In recent years, Chinese cosmetics manufacturing enterprises, through independent research and development and intelligent upgrades, have launched a number of efficient and precise filling equipment. These not only solve the pain points in traditional production but also drive the industry towards automation and green development. The following is an in-depth interpretation of the current industry trends and technological progress:

Technological Breakthroughs: Precise Filling and Anti-overflow Design as the CoreHigh-precision Servo Motor Control

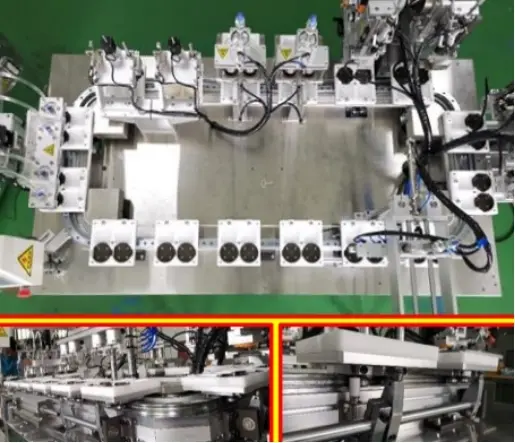

The new filling production line is driven by multiple sets of servo motors, precisely controlling the filling volume and speed. For example, the filling equipment of Guangzhou Haoruid Chuangsi Precision Technology Co., Ltd. achieves a filling accuracy of ±0.5g through the linkage of two sets of servo motors, combined with intelligent sensors and controlled by a PLC. This effectively solves the problem of overflow caused by uneven filling in traditional equipment.

Uniform Filling Technology

The air cushion BB cream filling device developed by Guangzhou Haoruid Chuangsi Precision Technology Co., Ltd. enables the paste to be evenly distributed, avoiding accumulation and overflow. This technology, combined with a ceramic antibacterial design, improves stability and reduces raw material waste. It is suitable for different formulations with high viscosity or strong fluidity.

Multifunctional and Multicolor Filling Adaptation Process

Through the design of detachable single-hole and multi-hole filling nozzles, it can flexibly meet the filling needs of materials with different viscosities and colors. For example, for high-viscosity materials, single-hole and single-color low-speed filling is adopted, while for low-viscosity materials, multi-hole rapid penetration is used, achieving multicolor pattern filling and significantly improving the utilization rate of the equipment.

Industry Trends: Emphasis on Both Automation and Environmental Protection

Popularization of Fully Automated Production Lines

The cushion BB cream filling device developed by Guangzhou Haoruid Precision Machinery Co., Ltd. uses ceramic cans to ensure a sterile environment and reduce raw material loss. The equipment is made of 304 stainless steel and is driven by a ring track servo system. The daily production output can reach 30,000 pieces, and the number of operators is reduced to 3 to 5 people. The filling efficiency and labor cost are increased by 50% compared with traditional models.

Innovation Driven by the Demand for Green Production

According to the "China BB Cream Industry Report 2025-2031", consumers' preference for environmentally friendly and natural ingredient products drives enterprises to use low-energy-consuming equipment. The new filling machine, through a vacuum recovery system, recovers and reuses the overflowed materials, reducing production waste by more than 30%.

Flexible Manufacturing to Cope with Market Segmentation

The categories of cushion BB creams are becoming increasingly diverse (such as sunscreen type and oil-control type), and the filling equipment needs to support small-batch customized production. For example, the production line of Coretronic adds an "artificial box supply area" and an "automatic ring pressing part", which is compatible with different specifications of packaging boxes and realizes the flexible switching of multi-functional use of one machine.

With the deep integration of 5G, AI technologies and filling equipment, future production lines will move towards the goals of "intelligence" and "zero waste". Industry experts point out that equipment manufacturers need to further optimize energy consumption and compatibility to meet consumers' higher expectations for personalized and sustainable beauty products.