Fully Automatic Cushion BB Cream Filling Machine Becomes the Preferred Choice in the Industry, with Five Core Advantages Helping Enterprises Seize the Market Initiative

With the intensification of competition in the beauty market and the improvement of consumers' requirements for product quality, the fully automatic cushion BB cream filling machine has become the first choice for cosmetics production enterprises to upgrade their equipment due to its characteristics of high quality, high efficiency, and high productivity. From technological innovation to cost optimization, from safety control to environmental adaptation, fully automatic filling equipment is redefining industry standards. The following is an in-depth analysis of its core competitiveness:

Ⅰ.The Revolution of Production Efficiency: The Automated Process Achieves a Leap in Production Capacity

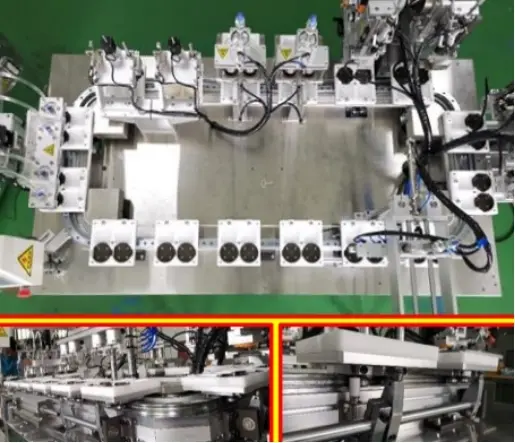

The fully automatic filling machine integrates processes such as feeding, filling, pressing the cream, pressing the inner ring, online automatic labeling, and unloading into a continuous production line through a circular track drive system and multi-station collaborative operation. For example, the filling equipment of Guangzhou Haoruide Chuangsi Precision Technology Co., Ltd. adopts the synchronous belt circular track transmission technology, and the material tray circulates on the circular track. The daily production capacity can reach 2,800-3,000 boxes per hour, which is more than 50% higher than that of traditional semi-automatic equipment.

Ⅱ.Precision Control Technology: The Servo System Ensures Stable Quality

Filling precision is the key to the production of cushion BB cream. Currently, mainstream equipment generally uses the linkage control of servo motors:

Filling Servo Motor: Through two sets of motors, the stroke and speed of the filling head are precisely regulated, and the error range can be controlled within 0.5g, solving the problems of overflow or uneven filling of traditional equipment.

Anti-overflow Technology: Due to the locking device used in the filling station, combined with the high-precision circular track, the matching precision between the filling head and the cushion box can be controlled within ±0.1mm. During filling, the servo motor is used for extrusion and exhaust to ensure the permeability of the filling of the material and the quantity of the filled material, completely avoiding the overflow of the filled material.

Constant Pressure Filling System: The fully automatic model of Guangzhou Haoruide Chuangsi Precision Technology Co., Ltd. effectively avoids the generation of bubbles through balanced pressure control and vertical servo screw technology, meeting the diversified needs of highly fluid or viscous paste materials.

Ⅲ.Flexible Adaptability: Modular Design for Multiple Uses with One Machine

In response to the diversity of cushion BB cream formulas (such as high-viscosity concealing type and low-viscosity translucent type), the fully automatic equipment can replace the filling head and the double-pressure material station to achieve free process switching:

Single-hole and Multi-hole Filling Nozzles: The patented technology of Jigao Network provides two types of filling heads. The single-hole low-speed filling is suitable for high-viscosity materials, and the multi-hole high-speed penetration is suitable for formulas with strong fluidity.

Ⅳ.Safety and Compliance: Intelligent Management and Control Reduces Risks

The fully automatic filling machine complies with international safety standards from the hardware to the operation process:

Dual Protection of Circuit and Machinery: Made of 304 stainless steel, it is equipped with a cascaded power-off switch and a overheat protection module to eliminate the risks of electric leakage or mechanical failure.

GMP Compliant Production: The non-contact design of the filling head and the vacuum anti-drip system ensure a sterile environment and product consistency, meeting the stringent certification requirements of the export market.

Operator Safety Training System: The equipment manufacturer provides a standardized training program, covering the whole process of emergency handling, maintenance, etc., reducing the rate of human operation errors.

Ⅴ.Cost-Effectiveness Optimization: Significant Long-term Return on Investment

Although the initial investment in fully automatic equipment is relatively high, its comprehensive cost advantages are significant:

Labor Cost Savings: The automated process reduces the dependence on manpower by 70%, and manpower is only required to participate in auxiliary links such as supplying boxes and rings.

Double Reduction of Energy Consumption and Waste: The energy consumption of the servo motor is 25% lower than that of the traditional motor.

Rapid Production Changeover Ability: The modular design supports the switching of the filling head and parameter adjustment within 1 hour, adapting to small batch customized orders and improving the utilization rate of the equipment.

Industry Outlook: Intelligent and Sustainable Development Advance Hand in Hand

According to the "2025-2031 Beauty Equipment Industry Forecast Report", the market size of fully automatic filling machines will grow at an average annual rate of 18%. In the future, technologies such as 5G remote monitoring and AI dynamic parameter adjustment will be further integrated into the equipment, promoting the popularization of "dark factories". By choosing a fully automatic filling machine, enterprises can not only cope with the current pressure of e-commerce explosive orders but also lay the foundation for green manufacturing and personalized production.