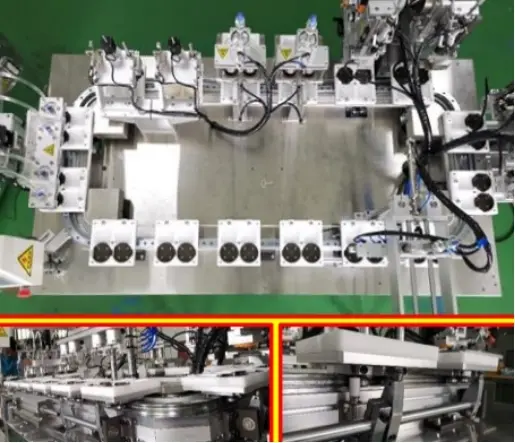

Uses and Classification of Automatic Labeling Machines

An automatic labeling machine is a device that can automatically paste labels onto products or packaging. It is widely used in various industries such as food, pharmaceuticals, daily chemicals, and electronics, greatly improving production efficiency and labeling quality.

In terms of uses, the automatic labeling machine first meets the basic need for product identification. In the food industry, it affixes production dates, ingredient lists, and brand labels to beverage bottles, cans, etc. In the pharmaceutical industry, through precise labeling, it marks the names of drugs, usage instructions, and expiration dates to ensure the safety of medication. For daily chemical products, labeling is used to display product ingredients, usage instructions, and other information, enhancing the brand image. In addition, the automatic labeling machine can also achieve anti-counterfeiting and traceability functions. By attaching labels with QR codes or barcodes, it is convenient for consumers to query the authenticity and traceability information of products, and it also helps enterprises manage product circulation.

According to different classification criteria, automatic labeling machines can be divided into various types. According to the labeling method, there are flat surface labeling machines, round bottle labeling machines, side labeling machines, and curved surface labeling machines, etc. Flat surface labeling machines are suitable for labeling flat objects such as cartons and paper boxes. Round bottle labeling machines are specifically designed for cylindrical bottles and can complete circumferential, side, or top labeling. Side labeling machines are used for labeling the sides of products, such as the ingredient instructions on the side of cosmetic boxes. Curved surface labeling machines can adapt to irregular curved objects, such as labeling spherical bottles. According to the degree of automation, they can be divided into semi-automatic labeling machines and fully automatic labeling machines. Semi-automatic labeling machines require manual placement of products, and the machine completes the labeling action. Fully automatic labeling machines can achieve the full automation of a series of processes such as product conveying, positioning, labeling, and detection, and are suitable for large-scale production scenarios.https://www.hrdautomaticequ.com/news/uses-and-classification-of-automatic-labeling-machines/