Product advantage

1.Filling characteristics

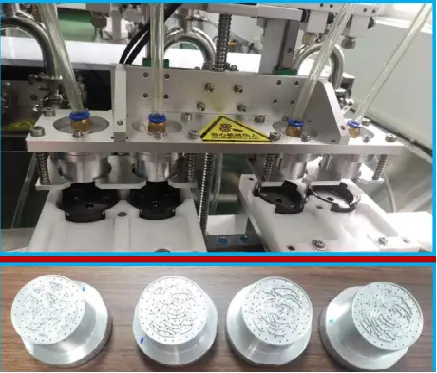

① Using four heads at the same time filling, filling efficiency can reach 3000 / hour.

② Can be multi-color filling, 1-4 colors can be, according to customer design pattern filling, not subject to color and shape restrictions.

③ The viscosity of the filling liquid can exceed 40000mpas, and the density of the sponge surface can exceed 50kg/m³, which greatly solves the limitations of the design ingredients.

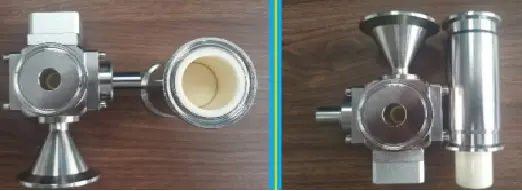

④ Ceramic pump is used in the filling liner to ensure easy cleaning and long-term guarantee the filling accuracy, which can be controlled within the error range of 0.5g.

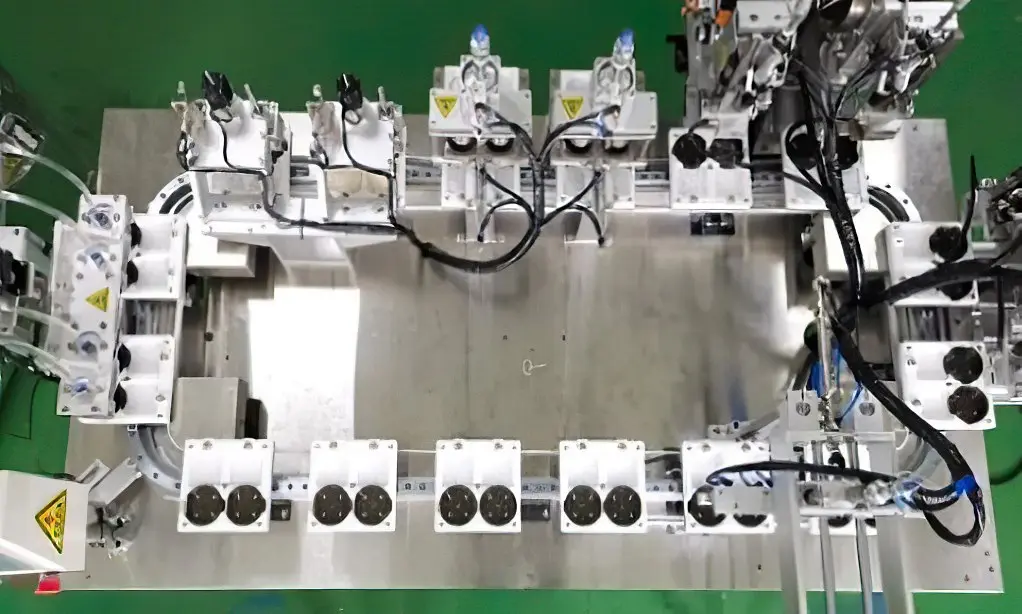

2.Conveying Method

The use of ring track conveying method to ensure the continuity of 16 stations, while ensuring the accuracy of stop station operation, controllable within ±0.05mm. This ensures the central position of the filling head, so that after pressing the middle circle, the liquid will not overflow, which greatly solves the previous situation of high defective rate, and the pass rate is as high as 99%.

3.automatic box taking device

Under the premise of ensuring no damage to the inner liner, scratching and other defects, the assembled makeup box is automatically removed from the pallet of the conveyor line by using the claw.

Place on the side conveyor belt for the next packing station operation. This greatly reduces the time and cost of manual box retrieval.

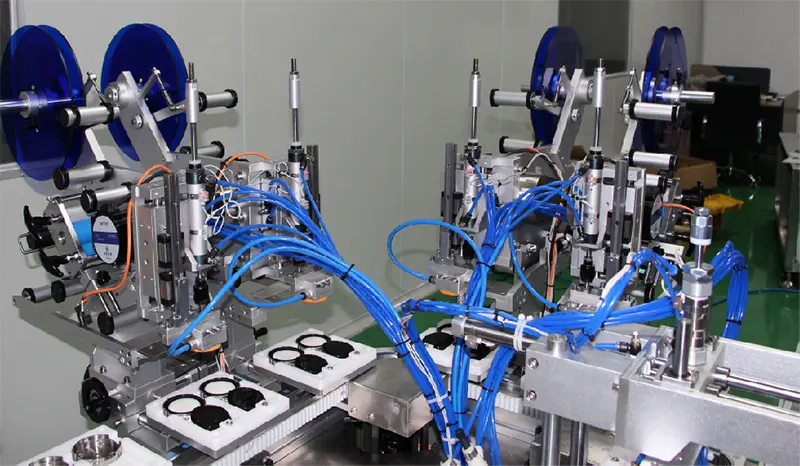

4.four head automatic sealing label

The automatic four-head sealing label is used at the same time to ensure that the labeling accuracy is controllable within 0.5mm, while improving the production capacity and reducing the labor cost.